Sparking off a diesel

Page 57

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

Spark ignition for starting might enable the compression-ignition engine to rival petrol performance By P. A. C. BROCKINGTON, A nn I Mach E

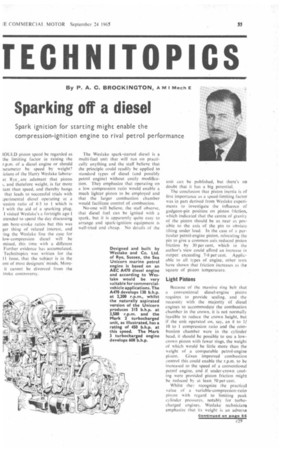

IOULD piston speed be regarded as the limiting factor in raising the r.p.m. of a diesel engine or should mrameter be speed by weight? licians of the Harry Weslake laboraat Rye., are adamant that piston

and therefore weight, is far more tant than speed, and thereby hangs that leads to successful trials with :perimental diesel operating at a .ession ratio of 6.3 to 1 which is 1 with the aid of a sparking plug. I visited Weslake's a fortnight ago ntended to spend the day discussing urn bore-stroke ratios but this was ger thing of related interest, and ing the Weslake line the case for low-compression diesel will be mined, this time with a different Further evidence has accumulated. Technitopics was written for the 11 issue. that the subject is in the ont of most designers' minds. Moreit cannot be divorced from troke controversy. The Weslake spark-started diesel is a multi-fuel unit that will run on practically anything and the staff believe that the principle could readily be applied to standard types of diesel (and possibly petrol engine) without costly modification. They emphasize that operating on a low compression ratio would enable a much lighter piston to be employed and that the larger combustion chamber would facilitate control of combustion.

No-one will believe, the staff observe, that diesel fuel can be ignited with a spark, but it is apparently quite easy to arrange and spark-ignition equipment is well-tried and cheap. No details of the

unit can be published, but there's no doubt that it has a big potential.

The conclusion that piston inertia is of first importance as a speed-limiting factor was in part derived from Weslake experiments to investigate the influence of gudgeon-pin position on piston friction, which indicated that the centre of gravity of the piston should be as near as possible to the axis of the pin to obviate tilting under load. In the case of a particular petrol-engine piston, relocating the pin to give a common axis reduced piston friction by 30 per cent, which in the author's view could afford an increase in output exceeding 7-8 per cent. Applicable to all types of engine, other tests have shown that friction increases as the square of piston temperature.

Light Pistons

Because of the massive ring belt that

a conventional diesel-engine piston requires to provide sealing, and the necessity with the majority of diesel engines to accommodate the combustion chamber in the crown, it is not normally feasible to reduce the crown -height, but if the unit operated on. say, an 8 to 1/ 10 to 1 compression ratio and the combustion chamber were in the cylinder head, it should be possible to usc a lowcrown piston with fewer rings, the weight of which would be little more than the weight of .a comparable petrol-engine piston. Given improved combustion control this could enable the r.p.m. to be increased to the speed of a conventional petrol engine, and if under-crown cooling were provided piston friction might be reduced by at least 50 per cent.

Whilst they recognize the practical value of a variable-compression-ratio piston with regard to limiting peak cylinder pressures, notably for turbocharged engines. Weslake technicians emphasize that its weight is an adverse

factor at higher speeds for the reasons stated, and that simplicity and low cost are essential features of any system that engine makers would consider for general use. The more serious stress problems associated with high inertia loads could be overcome by using a high-grade material such as titanium for big-end bolts and if necessary for the connecting rod, but the problem of heavy piston-bore pressures would remain. It is pertinent to note that at higher r.p.m. the downward thrust created by combustion is partly or wholly balanced by piston inertia for a substantial part of the stroke, and combustion loading on the bearings is. therefore, of secondary importance.

High-speed Snag

A major disadvantage of • a high compression ratio is that deflections of the piston/connecting-rod assembly that occur at higher speeds cause much larger variations in the effective compression ratio and in the combustion characteristics than do comparable deflections if a lower compression 'ratio is used, because of the reduced volume of the combustion chamber of the high-compression engine. Although the potential advantages of a low compression ratio, combined with a lightweight piston. are c40 applicable to longand short-stroke engines, they would possibly offer greater benefits to the former, the uprating of which represents a particularly vexed problem on account of piston-speed and inertia difficulties. The assumption might he valid that engines of up to 10 litres could be developed with a bore-stroke ratio of 1 to 1.3, or as much as 1 to 1-4. and a compression ratio of around 9 to 1 which would operate at over 3,500 r.p.m.

No Comparisons

So far as I know, no tests have been made to obtain a direct comparison between the minimum specific fuel consumption of a low-compression diesel and a petrol engine of the same capacity with a comparable compression ratio. A number of engine makers have built experimental high-compression petrol engines that give diesel-engine economy on full load when running on highoctane petrol, their main disadvantage, apart from the cost of the fuel, being poor economy at part loads. No information is available on any of these units, but it is probable that their compression ratios do not exceed about 12 to 1 and possibly. in one case, not more than 10 to 1, and this enhances the case for the low-compression diesel, with regard to economy. Is it not feasible, therefore, that a high-speed, lightweight, lowcompression, spark-started diesel could be built which had the output of a petrol engine of the same capacity and a fuel consumption that closely approached the normal consumption of a diesel through out its load/speed range? Maybe it depends on improving the air utilization of the diesel, which some authorities believe would be easier to achieve with a low-compression engine.

As a footnote, the paradox may be posed that piston inertia is not the bugbear that it was once supposed to be, that it is in fact a valuable aid to over all efficiency. As mentioned earlier, piston inertia absorbs at least a substantial proportion of the force of combustion at higher speeds, which is, therefore, utilized during the early part of the stroke to reverse the piston. The force is restored to the cycle lower in the stroke at a relatively large connectingrod/crank angle and gives improved mechanical efficiency as well as a reduction in bearing loads and structural deflections. By the very nature of things. burning must be completed near top dead centre. otherwise heat losses become excessive, and if it were not for piston inertia a far greater proportion of the combustion force would be absorbed in " stretching " the engine, The Wcslake staff agree with this premise.