Plastic Body for New Reliant

Page 98

If you've noticed an error in this article please click here to report it so we can fix it.

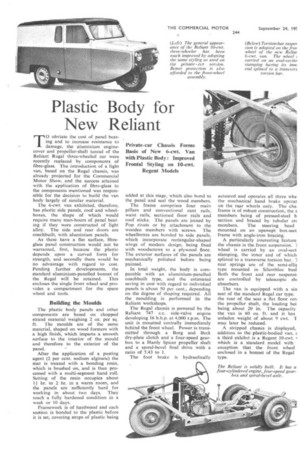

TO obviate the cost of panel beating and to increase resistance to damage, the aluminium enginecover and propeller-shaft tunnel of the Reliant Regal three-wheeled car were recently replaced by components of fibre-glass. The introduction of a light van, based on the Regal chassis, was already projected for the Commercial Motor Show, and the success attained with the application of fibre-glass to the components mentioned was responsible for the decision to build the van body largely of similar material.

The 6-cwt. van exhibited, therefore, has plastic side panels, roof and wheelboxes, the shape of which would require many man-hours of panel beating if they were constructed of light alloy. The side and rear doors are coachbuilt, with aluminium panels.

As these have a flat surface, fibreglass panel construction would not be warranted, first, because the plastic depends upon a curved form for strength, and secondly there would be no advantage with regard to cost. Pending further developments, the standard aluminium-panelled bonnet of the Regal will be retained. This encloses the single front wheel and provides a compartment for the spare wheel and tools.

Building the Moulds

The plastic body panels and other components are based on chopped strand material weighing 2 oz. per sq. ft. The moulds are of the same material, shaped on wood formers with a high finish, which imparts a smooth surface to the interior of the mould and therefore to the exterior of the panel.

After the application of a pasting agent (2 per cent. sodium alginate) the mat is treated with a bonding resin, which is brushed on, and is then processed with a multi-segment hand roll. Setting of the resin occupies about hr. to 2 hr. in a warm room, and the panels are sufficiently hard for working in about two days. They reach a fully hardened condition in a week or 10 days.

Framework is of hardwood and each seotion is bonded to the plastic before it is set, covering strips of plastic being added at this stage, which also bond to the panel and seal the wood members.

The frame comprises four main pillars and conventional cant rails, waist rails, sectioned floor rails and roof sticks. The panels arc joined by Pop rivets or by attachment to the wooden members with screws. The wheelboxes are bonded to side panels, which incorporate rectangular-shaped wings of modern design, being fixed with woodscrews to a plywood floor. The exterior surfaces of the panels are mechanically polished before being painted.

In total weight, the body is comparable with an aluminium-panelled coachbuilt type, and the estimated saving in cost with regard to individual panels is about 50 per cent., depending on the degree of shaping required. All the moulding is performed in the Reliant workshops.

The Regal chassis is powered by the Reliant 747 c.c. side-valve engine developing 16 b.h.p. at 4,000 r.p.m. The unit is mounted centrally immediately bchind the front wheel. Power is transmitted through a Borg and Beck dry-plate clutch and a four-speed gearbox to a Hardy Spicer propeller shaft and a spiral-bevel final drive with a ratio of 5.41 to 1.

The foot brake is hydraulically actuated and operates all three whe the mechanical hand brake operat on the rear wheels only. The cha: frame is of robust construction, the s members being of pressed-steel b section and braced by tubular cri members. The steering head mounted on an upswept box-sect frame with angle-iron bracing.

A particularly interesting feature the chassis is the front suspension. 1 wheel is carried by an oval-sect stamping, the inner end of which splined to a transverse torsion bar. rear springs are of the semi-ellir type mounted in Silentbloc bust Both the front and rear suspensii are controlled by telescopic du absorbers.

The van is equipped with a sin seat of the standard Regal car type. the rear of the seat a flat floor coli the propeller shaft, the loading hei being about 20 in. The capacity the van is 60 cu. ft. and it has unladen weight of about 9 cwt. T may later be reduced.

A stripped chassis is displayed, addition to the plastic-bodied van, 2

a third exhibit is a Regent l0-cwt. which is a standard model with exception that the front wheel enclosed in a bonnet of the Regal type.