CHASSIS

Page 64

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

ACCESSIBILITY—

Its Bearing Upon Body Design

READY access to the various parts of the chassis is desirable from the points of view of both maintenance and repair. The organization of the motorbus and coach garage has now reached a high state of efficiency, but much has to be done during the few hours in which the vehicles are in the garage, ini order that each vehicle shall receive systematic and adequate attention. Therefore any factol that saves time not only reduces the maintenancecosts but also makes easier the task of keeping the fleet in firstclass running order.

The chassis may be well designed to provide easy access, but if this quality is to be preserved the close co-operation of the bodybuilder is essential. When the body is mounted, the chassis, behind the dash, is entirely hovered from above, often for several inches below the top of the chassis at the sides and back, whilst the drivel's compartment may be built either at the side of the engine or completely to envelop the power unit.

The wing, no matter what the position of the front axle may be in relation to the centre of the engine, usually forms a large obstruction, because it is not only situated close to the bonnet, but is 'often more than a foot wide.

When the bus is provided with a forward-control cabin, no advantage is gained by detachingthe offside wing, because part of the base of the cabin is shaped to fit it. The bonnet must, therefore, be provided. with au'easily removable side panel. A hinged plate would be useless, owing to the close proximity of the steering column.

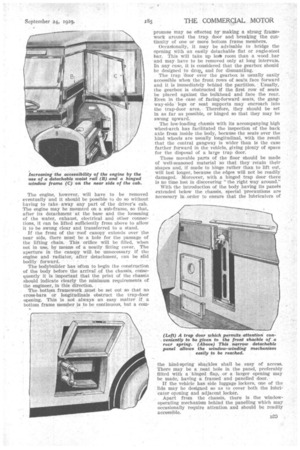

In order to give greater access to the engine, it may be desirable to design the near side of the half cabin so that the waist rail may be detached and the

window frame hinged back. With the near-side portion of the bonnet removed, the engine is then available for a wide variety of jobs. At the same time tti; engine is sufficiently exposed to permit its removal, if necessary, from the chassis.

Although the removal of the engine may be a rare occurrence, it may save time, provided that the 114et be standardized, to do so in the case of what might be considered in itself a minor repair.

The engine, however, will have to be removed eventually and it should be possible to do so without having to take., away any part of the driver's cab. The engine may be mounted on a sub-frame, so that, after its detachment at the base and the loosening of the water, exhaust, electrical and other connections, it can be lifted sufficiently from above to allow it to be swung clear and transferred to a stand. •

If the front of the roof canopy extends over the near side, there must be a hole for the passage of the lifting chain. This orifice will be filled, when not in use, by means of a neatly fitting cover. The aperture in the canopy will_ be unnecessary if the engine and radiator, after detachment, can be slid bodily forward.

The bodybuilder has often• to begin the construction of the body before the arrival of the chassis, consequently it is important that the print of the chassis should indicate clearly the minimum requirements of the engineer, in this direction.

The bottom framework "Mist be set out so that no cross-bars or longitudinals obstruct the trap-door opening. This is not always an easy matter if a bottom frame Member is to be continuous, but a corn

promise may De etteetea bymaking a strong frame. work around the trap door and breaking the euntinuity of one or more bottom frame members.

• Occasionally, it may be advisable to bridge the opening with an easily detachable flat or angle-steel bar. This will take up le A room than a wood , bar 'and may have to be removed only at long intervals. In any case, it is considered that the gearbox should be designed to drop, and for dismantling..

The trap 'door over the gearbox is usually easily accessible when the front, rows of seats, face forward and it is immediately behind the partition. Usually, the gearbox is obstructed if the first row of seats be placed against the bulkhead and face the rear. Even in the case of facing-forward-seats, the gang way-side legs or seat supports may encroach into the trap-door area. Therefore, they should be set in as far as possible, or hinged so that they may be swung upward.

The low-loading chassis with its accompanying high wheel-arch has facilitated the inspection of the back axle from inside the body, because the seats over the hind wheels are usually longitudinal, with the result that the central gangway is wider than is the case farther forward in the vehicle, giving plenty of space for the disposal of a large trap door.

These movable parts of the floor should be made of well-seasoned material so that they retain their shapes and, if made to hinge rather than to lift out, will last longer, because the edges will not be readily damaged. Moreover, with a hinged trap door there is no time lost in discovering "the right way around." With the introduction of the body having its panels extended below the chassis, special precautions are necessary in .order to ensure that the lubricators of

the hind-spring shapkles shall be easy of access. There may be a neat hole in the panel, preferably fitted with a hinged flap, or a larger opening may be made, having a framed and panelled door.

If the vehicle has side luggage lockers, one of the lids may be desigged so as to cover both the lubricator opening and adjacent locker.

Apart from the chassis, there is the windowoperating mechanism behind the panelling which may occasionally require attention and should be readily accessible. Zhouid a glass be. broken, there is seldom any difficulty in replacing it, as this can • usually be effected by removing the fillets above the waist line. Furthermore, there are balanced windows which are selfcontained and have no mechanism below the garnish rail. 3f, however, the window-lifting device be mounted under the light, it should not be necessary to remove any of the seats in order to repair or lubricate the mechanism. Removal of the seats may not be a lengthy operation if they be entirely supported from the floor and not partly from the side of the body. Even when the seat is removed, however, inside panels and mouldings have still to be detached.

It is suggested that the inside panelling should be arranged so that there is a narrow, detachable panel at the point at which the mechanism is situated. This could be suitably moulded at the edges and fixed with brass screws, cups, or metal thread screws, and tapped plates. These removable panels would be as deep as the mechanism,, if between the seats, or would reach to the cushion level if disposed at the seat position.