DRIVEN TO DRINK

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

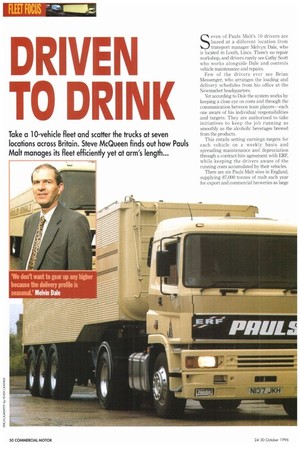

Seven of Pauls Malt's 10 drivers are based at a different location from transport manager Melvyn Dale, who is located in Louth, Lincs. There's no repair workshop, and drivers rarely see Cathy Scott who works alongside Dale and controls vehicle maintenance and repairs.

Few of the drivers ever see Brian Messenger, who arranges the loading and delivery schedules from his office at the Newmarket headquarters.

Yet according to Dale the system works by keeping a close eye on costs and through the communication between team players--each one aware of his individual responsibilities and targets. They are authorised to take initiatives to keep the job running as smoothly as the alcoholic beverages brewed from the products.

This entails setting earnings targets for each vehicle on a weekly basis and spreading maintenance and depreciation through a contrail-hire agreement with ERF, while keeping the drivers aware of the running costs accumulated by their vehicles.

There are six Pauls Malt sites in England, supplying 87,000 tonnes of malt each year for export and commercial breweries as large as Scottish Courage, as well as a growing number of independents.

Dale says: We have a site at Wallingford (Oxfordshire) which has two vehicles; one at Ipswich, which has none—Bury St Edmunds has three so it covers Ipswich— Louth, which has three; while Gainsborough, 35 miles away has none. Knapton (Yorkshire) some 80 miles away, has two. So it's basically five vehicles in the North and five in the South."

A number of independent operators bring in grain, which is the company's raw material. The grain is purchased at a delivered price so Pauls Malt has no responsibility for inward-bound vehicles. Its own vehicles deliver the processed malt but the company deliberately declines to deliver all of it.

"We aim to deliver only about 80% of the malt ourselves," says Dale. "We contract in the other transport requirements from a single haulier, Bartrum Haulage and Storage of Diss in Norfolk. We do this for operating efficiency reasons—we don't want to gear up any higher because the delivery profile is seasonal. For example, brewers don't take as much malt in January and February as they do in the run up to Christmas and Easter."

The company also shuns the opportunity to carry return loads, which means the vehicles run a significant amount of empty mileage: "We don't look elsewhere for haulage work—we would run the risk of missing our timed deliveries," says Dale.

All 10 of the Pauls Malt vehicles were supplied by ERF, but not all are part of the same deal. While the three older vehicles are wholly owned, the more recent acquisitions are part of a contract-hire agreement with the manufacturer.

In future, all of the Pauli; Malt fleet is likely to become part of the same contract, says Dale, as long as the deal is right.

ERF is currently favoured for two reasons. The first is historical. In 1985 the company had a contract-hire-plus-driver agreement, whereby BRS provided 80% of its transport. In 1987 Pauls Malt acquired a competitor, ABM, which had its own transport fleet, all ERFs. The initial tie was made.

''The other reason is more patriotic," says Dale, "We go into British breweries delivering British barley and we believe we should be using British trucks."

The latest EClOs are fitted with telephones to keep the drivers in touch with base and cruise control to save the drivers touching the accelerator, thereby conserving fuel and effort. Aluminium fuel tanks and alloy wheels have been specified to save precious vehicle weight, while at the same time enhancing the pristine image of the vehicles in the eyes of the customer.

Dale describes himself as a "transport enthusiast" who acquired the group transport responsibility by default. If that is true, it was the last time the company did anything concerning its vehicles without first studying the cost implications.

"Having taken over ABM, we had two different transport operations." he says. "It enabled us to consider the merits of the two systems side by side. We costed them over a period of six months to a year and decided to go back to managing and running our own fleet. We now have most of the fleet on a contract-hire basis through the manufacturer. In maintenance terms this saves us a lot of time and makes the operation much slicker."

This process extends to encouraging the driver on the spot to use initiative in certain situations.

"If there is a breakdown or any nonscheduled maintenance the driver deals through me, but the manual (introduced earlier this year) lays out the responsibilities and which jobs he has the authority to get done if I'm not available," says Dale.

For example, if there are any tyre problems the drivers know what to do. "We prefer to run on new tyres all round," he explains. "We never use remoulds. Our view is that we get more economical use by wearing down new tyres and returning the casings than we ever do out of running on remould tyres." He says the drivers must have the right attitude or the Pauls Malt system wouldn't work.

'It's not so much about experience or knowledge about malt deliveries. We need mature people with the right attitude who can take responsibility for keeping the job moving," says Dale.

By way of proof, the average length of service is 14 years and the average age is 52. Dale believes one reason why the company gets the best out of its drivers is because of its contract of employment.

"There are no differences between them and the rest of us in terms of pensions and benefits," he says. "They don't get overtime payments, they get no extras for keeping the lorry clean; only a night out allowance. The package is designed to motivate them, to make them feel they are part of a team. We sell malt on an annual contract—the driver goes in weekly and is the only real contact with the customer, so he has a lot 'of responsibility. He must be presentable and so must the vehicle."

As a food carrier, adherence to food safety legislation is paramount and hygiene is everything. Each driver is responsible for making sure that his trailer is swept, clean and dry before loading.

Hygiene is closely linked with safety and not just from a food quality point of view. Loading is a daily hazard because of rising dust and every load must be securely sheeted from the top. All drivers are equipped with airstream masks and hard hats. The trailers are all semi-enclosed to include a walkway with ladder and handrail. A safety harness is also supplied for use when the driver goes topside.

The vital use of this equipment is underlined through quarterly meetings, where Dale catches up with all the outlying drivers to make them aware of the running costs of their vehicles.

He also discusses any news about changes to legislation, tachograph analysis and training initiatives, as well as health and safety issues.

So while it might be true that the Pauls Malt fleet is operated at arm's length, there is no doubt about the quality of the controls that keep it running efficiently.