GOOD PERFORMANCE By ? I :3111 1 . °m'

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

AT 14 TONS GROSS

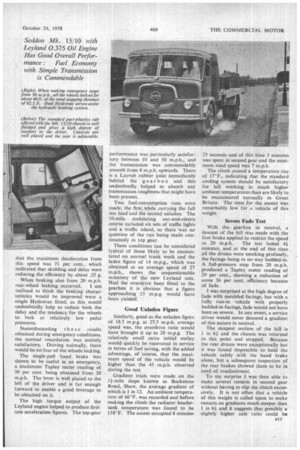

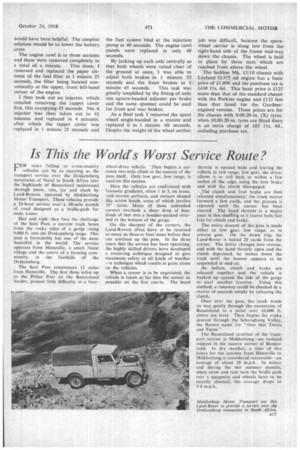

SINCE its introduction at the beginning of this year, the Seddon Mk. 15/10 14-ton-gross fourwheeler has proved popular with longdistance hauliers for loads of 9-10 tons. Originally offered with a choice of Perkins or Gardner oil engines, it is now available with a third unit—the Leyland 0.375 110 b.h.p. engine.

It has been road tested with the Leyland engine, and provisional results were briefly given in The Commercial Motor on September 19. These figures showed that the vehicle is commendably economical and has . good acceleration characteristics.

The test also revealed that the Seddon lacked nothing in hill-climbing performance, whilst the braking system was, if anything, too powerful for a grOss weight of 14 tons. The vehicle handled well and the cab gave a high degree of comfort.

Leyland 0375 Engine The Leyland 0.375 .engine has the same external dimensions as the lowerpowered 0.350 unit, being virtually a bored-out version of it.

A Meadows 250 C5 five-speed constant-mesh gearbox is standard in all models of the Mk. 15/10. When employed .with the Leyland engine, this gearbox has the same ratios as are used with the Perkins R6 unit and at present a 13-in.-diameter clutch is installed with both engines, although a 14-in. diameter unit will later be fitted to the Leyland engine. The Meadows box coupled to the Gardner 4LW engine (which also has a 14-in, clutch) has closer ratios than in the other applications.

Alternative to the Meadowssearbox, however, is the Albion five-speed constant-mesh unit and it was this box which was fitted to the vehicle supplied for test. At extra cost it may be supplied with an overdrive sixth speed. Alternatively, the sixth speed can be incorporated in the gearbox at a later date merely by removing spacers on the gear shafts and replacing them with a set of gear wheels.

Other than the availability of the optional power units, the specification of the Mk. 15/10 has remained unchanged basically since its introduction last February. The Aeon hollow-rubber helper springs formerly fitted at both axles have, however, been dispensed with.

The chassis frame also has been modified slightly. The maximum sidemember depth is now 9 in., an increase of in., and the .frame flanges are parallel throughout the greater part of their length. The 9.00-20-in, nylon tyres formerly offered as standard are replaced by Michelin X 10.00-20-in. equipment carried on three-piece wheels with B7.00 rims.

As supplied for test the Mk. 15/10 had the standard plastics-panelled cab and a Seddon-built 20-ft. light-alloy platform body with timber flooring. This was a non-standard body, a 19-ft. body being provided normally on this chassis.

Test weights totalling 9 tons 101 cwt. had been loaded on to the body, specially wedged to prevent movement during braking. With Frank Galbraith, of Seddon, and myself, the vehicle was tested at a gross weight of 14 tons 24 cwt., the front-axle loading being 5 tons 31 cwt.

Wide, Level Road

For the first series of tests the vehicle was taken out to the Heaton Park area, a wide, level stretch of littleused road being used for the braking and acceleration trials. The power of the braking system was such that all four wheels could be locked without much effort.

Unfortunately, there was evidence of lag in line-pressure build-up, presumably because of the size of the two Atlas Hydrovacs, and this resulted in longer stopping distances being obtained than initial acquaintance with the system would suggest.

If this lag can be reduced I have no doubt that the vehicle will stop from 30 m.p.h. in under 50 ft. As it was, when braking from this speed the average stopping distance was 62.5 ft. and the wheels were locked for no less than 40 ft. The Tapley meter showed that the maximum deceleration from this speed was 71 per cent., which indicated that skidding and delay were reducing the efficiency by about .25 g.

When braking also from 20 m.p.h.

rear-wheel locking occurred. I am inclined to think the braking characteristics would be improved were a single Hydrovac fitted, as this would undoubtedly help to reduce both the delay and the tendency for the wheels to lock at relatively low pedal pressures.

Notwithstanding t h ese results obtained during emergency conditions, the normal retardation was entirely satisfactory. Driving noimally, there would be no fear of the wheels locking.

The single-pull hand brake was shown to be useful in an emergency, a maiimum Tapley meter reading of 30 per cent. being obtained. from 20 m.p.h. The lever is well placed to the left of the driver and is far enough forward to enable a good leverage to be obtained on it.

The high torque output of the Leyland engine helped to produce firstrate acceleration figures. The top-gear performance was particularly satisfactory between 10 and 30 m.p.h., and the transmission was commendably smooth from 8 m.p.h. upwards. There is a Layrub rubber joint immediately behind the g ear box and this undoubtedly helped to absorb any transmission roughness that might have been present.

Two fuel-consumption runs were made, the first while carrying the full test load and the second unladen. The 10-mile undulating out-and-return course included six sets of traffic lights and a traffic island, so there was no question of the run being made continuously in top gear.

These conditions can be considered typical of those likely to be encountered on normal trunk work and the laden figure of 14 m.p.g., which was obtained at an average speed of 27 m.p.h., shows the unquestionable economy of the new Leyland unit. Had the overdrive been fitted to the gearbox it is obvious. that a figure approaching 15 m.p.g. would have been yielded.

Good Unladen Figure

Similarly, good as tile unladen figure of 18.5 m.p.g. at 27.5 m.p.h. average speed was, the overdrive ratio would have brought it up to 20 m.p.g. The relatively small extra initial outlay would quicklybe recovered in service in terms of fuel saving, with the added advantage, of 'course, that the maximum speed of the vehicle would be higher than the 45 m.p.h. observed during the test.

Gradient trials were made on the 11-mile slope known as Buckstone Road, Shaw, the average gradient of which is 1 in 12. An ambient temperature of 66°F. was recorded and before making the climb the radiator headertank temperature was found to be 158°F. The ascent occupied 8 minutes 25 seconds and of this time 3 minutes was spent in second gear and the minimum road speed was 7 m.p.h.

The climb caused a temperature rise of 17°F., indicating that the standard cooling system should be satisfactory for hill working in much higher ambient temperatures than are likely to be encountered normally in Great Britain. The time for the ascent was remarkably low for a vehicle of this weight.

Severe Fade Test

With the gearbox in neutral, a descent of the hill was made with the foot brake applied to restrict the speed to 20 m.p.h. The test lasted 4+ minutes, and at the end of this time all the drums were smoking profusely, the facings being in no way bedded-in. A full-pressure stop from 20 m.p.h. produced a Tapley meter reading of 29 per cent., showing a reduction of some 36 per cent, efficiency because of fade.

I was surprised at the high degree of fade with moulded facings, but with a fully run-in vehicle with properly bedded-in facings, fade would not have been so severe. In any event, a service driver would never descend a gradient of this nature in neutral.

The steepest section of the hill is I in 61 and the chassis was returned to this point and stopped. 13ecause the rear drums were exceptionally hot it was found impossible to hold the vehicle safely with the hand brake alone, but a subsequent inspection of the rear brakes showed them to be in need of readjustment.

To my surprise I was then able to make several restarts in second gear without having to slip the clutch excessively. It is not often that a vehicle of this weight is called upon to make restarts on gradients much steeper than 1 in 6+ and it suggests that possibly a slightly higher axle ratio could be

employed to give a greater maximum speed and possibly improve the fuel consumption and acceleration without affecting the gradient performance.

I drove the Seddon during most of the test and was pleased with its characteristics. Although the steering is unassisted, it was comfortably firm at normal speeds and not excessively heavy at walking pace despite the axle loading of over 5 tons. The castor action is of assistance on corners, although a slight kick at the steering wheel was noted on several occasions over rough surface.

The suspension gave a comfortable ride when laden, telescopic dampers being standard at the front axle, but when running empty the rear end tended to buck a little, which could produce slight discomfort in the cab at high speeds.

No further comment on the gearbox is required, for 1 have frequently praised it. By virtue of its short gearlever travel and light action, it permits even easier gear changing than is possible with most synchromesh boxes and, indeed, makes use of the clutch superfluous for normal purposes.

The engine is willing and works smoothly at all speeds without being excessively noisy. It idles well and at no time was any smoking at the exhaust outlet observed,

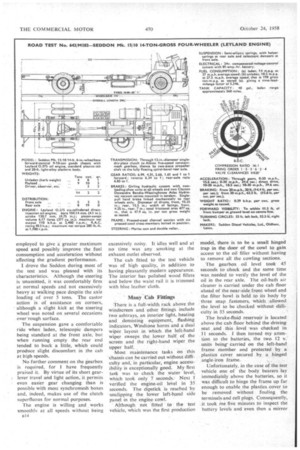

The cab fitted to the test vehicle was of high quality, in addition to having pleasantly modern appearance. The interior has polished wood fillets and below the waist rail it is trimmed with blue leather cloth.

Many 'Cab Fittings

There is a full-width rack above the windscreen and other fittings include two ashtrays, an interior light,heating and .demisting 'equipment, flashing indicators, Windtone horns and a dual wiper layout in which. the left-hand wiper sweeps the lower half of the screen and the right-hand wiper the upper half.

Most maintenance tasks on this chassis can be carried out without difficulty and, in particular, engine accessibility is exceptionally good. My first task was to check the water level, which took only 7 seconds.\ Next 1 verified the engine-oil level in 35 seconds. The dipstick is reached by unclipping the lower left-hand side panel in the engine cowl.

Although riot fitted to the test vehicle, which was the first production

model, there is to be a small hinged trap in the door of the cowl to gain access to the oil filler without having to remove all the cowling sections.

The gearbox oil level took 45 seconds to check and the same time was needed to verify the level of the oil in the rear axle. The oil-bath air cleaner is carried under the cab floor

ahead of the near-side front wheel and the filter bowl is held to its body by three snap fasteners, which allowed the level to be checked without difficulty in 35 seconds.

The brake-fluid reservoir is located above the cab floor behind the driving seat , and this level was checked in 11 seconds. I then turned my attention to the batteries, the two 12 v. units being' carried on the left-hand frame member and protected by a plastics cover secured by a hinged angle-iron frame.

Unfortunately, in the case of the test vehicle one of the body bearers lay immediately above the batteries, so it was difficult to hinge the frame up far enough to enable the plastics cover to be removed without fouling the terminals-and cell plugs. Consequently, . it took me five minutes to inspect the battery levels and even then a mirror would have been helpful. The simplest solution would be to lower the battery crate.

The engine cowl is in three sections and these were removed completely in a total of a minute. This done, I removed and replaced the paper element of the fuel filter in 1 minute 25 seconds, the filter being located conveniently at the upper, front left-hand corner of the engine.

I then took out an injector, which entailed removing the tappet cover first, this occupying 45 seconds. No. 6 injector was then taken out in 4* minutes and replaced in 4 minutes, after which the tappet cover was replaced in 1 minute 25 seconds and the fuel system bled at the injection pump in 40 seconds. The engine cowl panels were replaced in only 48 seconds.

By jacking up each axle centrally so that both wheels were raised clear of the ground at once, I was able to adjust both brakes in 1 minute 35 seconds and the front brakes in 1 minute 45 seconds. This task was greatly simplified by the fitting of only one square-headed adjuster per brake and the same spanner could be used for front and rear brakes.

As a final task I removed the spare wheel single-handed in a minute and replaced it in 1 minute 40 seconds. Despite the weight of the wheel neither job was difficult, because the sparewheel carrier is slung low from the right-hand side of the frame mid-way down the chassis. The wheel is held in place by three nuts which are reached from above the wheel.

The Seddon Mk. 15,110 chassis with Leyland 0.375 oil engine has a basic price of £1,896 and the purchase tax is £438 11 s. 6d. This basic price is £125 more than that of the standard chassis with the Perkins engine and £125 less than that listed for the Gardnerengined version. These prices are for the chassis with 9.00-20-in. (X) tyres: when 10.00-20-in. tyres are fitted there is an extra charge of £65 11 s. 4d„ including purchase tax.