SYNCHRONIZED TANKER

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

SERVICE SELLS By AF. Smith, LIQUID glucose is not normally stored for long periods by consumers, and they must therefore have punctual deliveries synchronous with their production requirements. In the case of the biggest users, late

arrival of a tanker may disjoint not only the production programme but also their schedule for unloading a succession of vehicles throughout the day.

Tunnel Glucose Refineries, Ltd., whose up-to-date plant lies within a stone's throw of the Greenwich entrance to the Blackwall Tunnel, have set out more than to satisfy their customers in this respect, as service is considered to be a major factor in successful sales.

Bulk Tonnage The trend towards the delivery of this product in bulk rather than in drums has accelerated during the past 10 years. Before then about half the tonnage was sent out in bulk, but today it is nearer 90 per cent., apart, of course, from export trade.

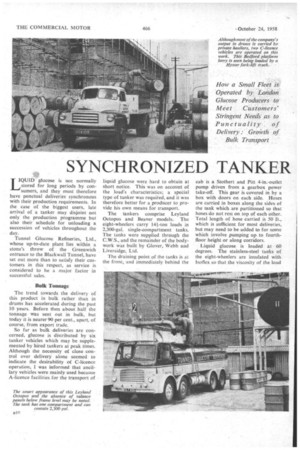

So far as bulk deliveries are con cerned, glucose is distributed by six tanker vehicles which may be supple mented by hired tankers at peak times. Although the necessity of close control over delivery alone seemed to indicate the desirability of C-licence operation, I was informed that ancillary vehicles were mainly used because A-licence facilities for the transport of liquid glucose were hard to obtain at short notice. This was on account of the load's characteristics; a special type of tanker was required, and it was therefore better for a producer to provide his own means for transport.

The tankers comprise Leyland Octopus and Beaver models. The eight-wheelers carry 141-ton loads in 2,300-gal, single-compartment tanks. The tanks were supplied through the C.W.S., and the remainder of the bodywork was built by Glover, Webb and Liversidge, Ltd.

The draining point of the tanks is at the front; and immediately behind the cab is a Stothert and Pitt 4-in.-outlet pump driven from a gearbox power take-off. This gear is covered in by a box with doors on each side. Hoses are carried in boxes along the sides of the tank which are partitioned so that hoses do not rest on top of each other. Total length of hose carried is 50 ft., which is sufficient for most deliveries, but may need to be added to for some which involve pumping up to fourthfloor height or along corridors.

Liquid glucose is loaded at 60 degrees. The stainless-steel tanks of the eight-wheelers are insulated with Isoflex so that the viscosity of the load can be maintained at a level consistent with easy unloading for at least four days.

This is a more stringent requirement than applies to certain other loads carried in bulk and is explained by the fact that liquid glucose cannot he reheated by steam coils if its temperature falls too low. This could cause a deterioration of the product.

The tank insulation allows for a 5degree drop in 24 hours. The lowest temperature at which liquid glucose has ever been unloaded was 35 degrees, an extreme exception which occurred one winter and was probably near the limit which could be tolerated.

The Beavers carry 6-ton loads. Two have stainless-steel tanks and the others have mild steel lined with a plastics coating. Time needed to load an Octopus is 12-15 minutes and unload 30-40 minutes, with the times for the 6-tonners in proportion.

Staff's Ideas When the recently acquired Octopus tankers were in the design stage, all drivers, mechanics and transport staff were invited to contributeto their specification. Among the requirements were ease of hose stowage and cleaning, ease of maintenance, including washing, and minimum vulnerability of bodywork when maneeuvring in confined spaces.

Emphasis was placed upon good appearance and lines, coupled with a colour scheme which would not readily show up mud on long journeys. For this reason in the two-tone colour scheme the lower colour tends towards neutrality, thus giving little contrast to mud. Tunnel's colour scheme of turquoise and grey is also chosen for publicity purposes. The sides of the bodies are panelled in for -tidy appearance, but vertical surfaces are not continued well below frame level in the manner of valances because of the vulnerability of such embellishments.

Need for delivery at specified times dictates the drawing-up of a schedule each Friday afternoon for the following week's work. • This is based on customers' ascertained needs and usually. covers three-quarters of actual work, the remainder representing urgent demands. On London work, the eight wheelers can do two deliveries a day and the Beavers three.

Two other tankers on continuous hire to Tunnel work in and out of the plant. These belong to North Cheshire Motors, Ltd., and carry a starch byproduct. One of these vehicles was made by Transport Vehicles (Warrington), Ltd. Tunnel have two platform vehicles for the distribution of liquid glucose in drums, but most of this traffic is handled by hauliers, chiefly Messrs. Coward Bros.

The drums themselves weigh 1 cwt. and contain 54 cwt. A depot is maintained at Plymouth for the supply of the hinterland to that town. Loads of 16-18 tons are sent down when necessary to replenish stocks.

At one time the railways were employed to carry drums until, with the advent of the denationalization of road transport, better service and much lower rates were available from free hauliers.

The company are self-sufficient concerning maintenance. Each vehicle covers over 20,000 miles a year, the Octopus tankers running greater mileages than the four-wheelers as customers able to take 12-14-ton deliveries preponderate outside London. They and two Beavers have Tecalernit Syndromic chassis lubricators and the other two vehicles are greased weekly.

Fuel Consumption Mobiloil Delvac engine oil is changed at 6,000 miles. Fuel is supplied by Shell-Mex and B.P. and average consumption rates are: Octopus, 10 m.p.g.; six cylindered Beaver, 12 m.p.g.; four-cylindered Beaver, 14-16 m.p.g.

The eight-wheelers are still running on their original Dunlop tyres, but the Beavers have been fitted with Michelin Metallics which are taken off at 45,000mile intervals for retreading. Some covers have, however, been rejected as the result of contamination by excess oil from the continuously lubricated steering joints and king pins. Other tyres 'suffer • from kerbing when vehicles are taken through the Blackwall Tunnel.

A good safety record is held by the drivers, who are entitled to an accident-free bonus every quarter. Currently Tunnel are selling hard a new kind of liquid glucose called Sweetose, which is claimed to offer certain advantages over other brands, and the fleet is to be expanded.