Putting a spring in your step

Page 96

Page 97

Page 98

If you've noticed an error in this article please click here to report it so we can fix it.

Given the rough ride they get on today's crumbling roads, it is surprising that steel springs do not break more often. Peter Watt looks at a few companies that can help when they do

• Considering the wave of high technology that is sweeping across modern commercial vehicles, it is somewhat surprising that a great number of new trucks are suspended on thin sheets of steel clamped loosely together. As we shall see, however, the low cost and ease of repair of the multi-leaf spring can still make it the most sensible choice for certain applications.

The springing medium has a vital function to play on any vehicle. Not only does it insulate the driver and the load from road irregularities, it also prevents such disturbances from damaging the chassis. At the same time, the springs must support the weight of the loaded vehicle, and provide springing characteristics which lead to good vehicle handling.

Conflicting demands

Because of these often conflicting demands, only two other general types of springing have arisen to challenge the long-established leaf. Air springing (which will not be considered in this article) is one such, and can offer performance advantages over steel. Air provides a better ride (important when fragile loads are being carried), and is often used on trailers when compactness and load bearing capacity is important. To be set against this, however, is the increased cost, complexity and, to a certain extent, vulnerability inherent in air systems.

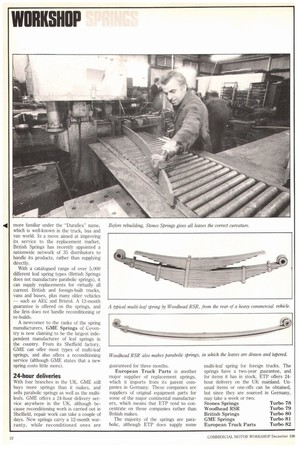

The other main alternative to the multileaf spring is the parabolic spring, which is a more sophisticated version of the leaf. The main difference is that a parabolic spring has a tapered profile — the thickness varies along its length. A parabolic spring has, weight for weight, a greater load capacity than a multi-leaf spring. Fitting parabolic springs, therefore, leads to a lighter vehicle, and thus to a higher payload for the operator.

Not surprisingly in these productivityconscious times, parabolic springs have gradually begun to take over from multi leafs. In addition to their lower weight, they are also claimed to be longer lasting, and to have a more progressive springing action. Their disadvantages, however, include higher cost, and their inability to be repaired. Perhaps more important for a lot of people, though, is that when a parabolic spring breaks, the vehicle is stranded. Multi-leaf springs, by contrast, offer a limited "get-you-home" capability.

For these reasons, some manufacturers are now offering a choice between multileaf and parabolic. This allows operators working on building sites or quarries (where large, heavy objects are often dropped onto a waiting vehicle, with ob vious consequences) to choose the more practical multi-leaf.

With the countless up-and-down movements they have to make and the punishment dished out by ever-worse road surfaces, springs on today's hard-worked trucks often have a finite life. A healthy replacement and repair market has developed in response to this, and the companies involved in this range from small, self-contained businesses to larger companies with national networks.

Thoroughly examined

An example of the former is Stones Springs of Bristol. With its team of ex perienced staff, Stones has been in the multi-leaf spring business for over 25 years. It offers a reconditioning service, and can also make new springs for any vehicle (within reason). A visit to its workshops will reveal not only truck springs, but also those for cars, steam locomotives and horse-carts.

When reconditioned, each multi-leaf spring is stripped down, tempered in the furnace (to restore the desired metal properties), then thoroughly examined for any faults. All suspect leafs are replaced by new, then the spring is reassembled to the correct camber settings. New clip bolts, centre bolts and bushes are always used, and the spring is painted before being returned to the customer.

Serving the area around Bristol, Stones has six vans which collect and deliver springs to its customers — both large fleet users and smaller operators. Using its experience of multi-leaf spring design, Stones can also uprate a spring where the manufacturer's original design proves too weak for the usage.

'Same day' offer

For all its springs, both new and reconditioned, Stones offers a six-month guarantee, and although not produced on the premises, Stones will also supply pa rabolic springs where required. A particular feature of the service from Stones is its "same day" offer, which ensures that an operator's spring will be returned within the day to prevent unnecessary downtime (at no extra cost).

At the other end of the scale in terms of size comes Jonas Woodhead, one of Europe's largest spring manufacturers. Its subsidiary, Woodhead RSR, serves the replacement spring market, and has set up over 30 branches throughout Great Britain, and in so doing claims to be market leaders.

Its new multi-leaf springs are manufactured both at the central plant and at many of the branches, and should include models to satisfy any truck, bus or trailer operator. The parabolic springs are only manufactured centrally, but Woodhead has set up regional stocking centres with stocks of over 300 springs to support the stocks held in the individual branches. All new springs are offered with a 12 month warranty.

Woodhead RSR also offers exchange and reconditioning services through its branches, with the reconditioned product coming with a six-month warranty. Each branch will attempt to provide a 24-hour or even same-day service if possible, and can take on multi-leaf springs from any model or age of truck. The branches have pick-up and delivery vans for their customers.

Another large manufacturer of springs which supplies both to the replacement and to the original equipment market is British Springs. Its product is perhaps

more familiar under the "Duraflex" name, which is well-known in the truck, bus and van world. In a move aimed at improving its service to the replacement market, British Springs has recently appointed a nationwide network of 35 distributors to handle its products, rather than supplying directly.

With a catalogued range of over 5,000 different leaf spring types (British Springs does not manufacture parabolic springs), it can supply replacements for virtually all current British and foreign-built trucks, vans and buses, plus many older vehicles — such as AEC and Bristol. A 12-month guarantee is offered on the springs, and the firm does not handle reconditioning or re-builds.

A newcomer to the ranks of the spring manufacturers, GME Springs of Coventry is now claiming to be the largest independent manufacturer of leaf springs in the country. From its Sheffield factory, GME can offer most types of multi-leaf springs, and also offers a reconditioning service (although GME states that a new spring costs little more).

24-hour deliveries

With four branches in the UK, GME still buys more springs than it makes, and sells parabolic springs as well as the multileafs. GME offers a 24-hour delivery service anywhere in the UK, although because reconditioning work is carried out in Sheffield, repair work can take a couple of days. New springs carry a 12-month warranty, while reconditioned ones are guaranteed for three months.

European Truck Parts is another major supplier of replacement springs, which it imports from its parent companies in Germany. These companies are suppliers of original equipment parts for some of the major continental manufacturers, which means that ETP tend to concentrate on those companies rather than British makes.

The majority of the springs are parabolic, although ETP does supply some multi-leaf spring for foreign trucks. The springs have a two-year guarantee, and for items it has in stock, ETP offers 24hour delivery on the UK mainland. Unusual items or one-offs can be obtained, but since they are sourced in Germany, may take a week or two.

Stones Springs Turbo 78 Woodhead RSR Turbo 79 British Springs Turbo 80 GME Springs Turbo 81 European Truck Parts Turbo 82