TRUCKBUILDING RALLY ROUND

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

Drawing upon a great tradition of truck engineering Unipower not only turns out spares for several former Scammells, but also plans to make its mark in the specialist heavyweights market.

• There's a discordant mix of styles at Unipower's new factory in Watford. The smart new offices are redolent of international banking, or high-tech publishing, but there's not a bottle of hair gel, or a pair of stripey braces to be seen. Cardigans mix with computers; grey hair clashes with pastel office decor, and the lined faces of experience rough it with smooth plastic desk tops — for here resides more than 420 combined years of experience in building specialist lorries, most of which was gained with Scanunell at the To!pits Lane site in Watford.

The facts of the case are clear. Leyland merged with Daf in February 1987, and Scammell was one of the victims. The 55-year-old company was closed with the loss of around 700 jobs. Leyland Daf now owns the Scammell name, together with the intellectual rights to the Scammell S26, the Routeman, and the Land Train.

After a period of Special Trucks, and an abortive management buyout, all hope for Scammell looked dead, and the workforce started to look for alternative employment. It was then that Unipower Group chairman Peter Rotherowe bought the licence to manufacture and supply parts for the former Scanunell; Commander, S24, Contractor, Explorer, Crusader, the Thornycroft Antar and, most importantly, the frontand rear-engined Nubian fire tenders. What Rotherowe had done, of course, was to buy out the competition for his own Unipower crash tender, gaining a number of other vehicles in the process.

Of the mix of vehicles that were thrown into the negotiations with Leyland Daf, Unipower has gained three up-to-date models which it can promote: the S24, the Commander, and the Crash Tender. In addition there is the important business of supplying spares back-up for all models.

NEGOTIATIONS

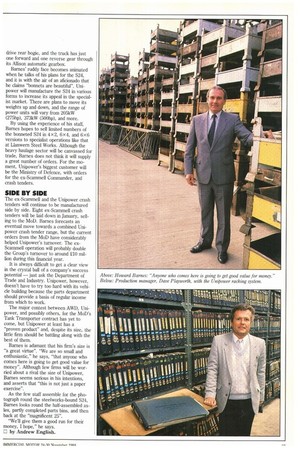

Although Unipower's sturdy managing director Howard Barnes was not thrown on to the table at the negotiations, the weekend of the talks were eventful for him. The erstwhile truck racer, and sales and marketing director for Scammell, received a phone call before Easter offering him the managing directorship. Within 48 hours, he had decided to head the fledgling operation, and started to round up former Scammell employees to join him. Acting like Yul Brynner in The Magnifkent Seven, Barnes cajoled and persuaded the best of the once-proud team out of secure jobs, and into the Watford operation. He now has a workforce of 25, including production manager Dave Playworth, sales manager Glynne Rees, and a formidable engineering department from the assembly workers to the drawing office. All claim to be able to turn their hands to anything, and in many cases they do.

The task facing the company is gargantuan; although much is already completed. the ex-Scammell spare parts and racking system are being assembled in the building behind the offices. The parts are being computer listed for easy location by the mechanical picker, and there are parts to be retooled and supplied to customers. Finding a particular door handle, or brake drum can take hours.

Trade in the spare parts is brisk, especially since the Army's Donnington warehouse fire, when a large number of Commander parts were destroyed and had to be replaced. This, the main part of the company's operation — selling spares and supplying them to all parts of the globe — will be the bread-and-butter income to finance the retooling of other areas, and the modest production of trucks.

Playworth says the entire racking system will be up and running by early next year and, considering what he has managed with his small workforce since August, one can only believe him.

PROPRIETARY PARTS

Unipower is supplying parts for its trucks to the Leyland Daf Multipart organisation, and is buying proprietary parts like oil filters from the same source. Parts are delivered using overnight couriers. Local haulage firms deliver heavier items. In many cases this is unnecessary because organisations like the Army will take a batch of parts straight from the subcontractor to put into its own stores.

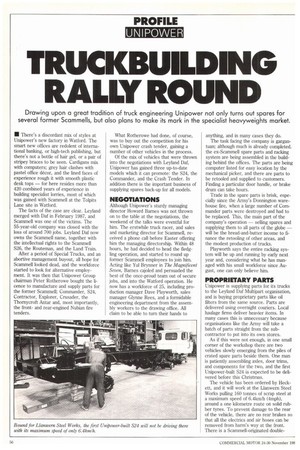

As if this were not enough, in one small corner of the workshop there are two vehicles slowly emerging from the piles of crated spare parts beside them. One man is patiently assembling axles, door trims, and components for the two, and the first Unipower-built S24 is expected to be delivered before this Christmas.

The vehicle has been ordered by Heckett, and it will work at the Llanwern Steel Works pulling 160 tonnes of scrap steel at a maximum speed of 6.4km/h (4mph), around a one kilometre route on solid rubber tyres. To prevent damage to the rear of the vehicle, there are no rear brakes so that all the electrics and air hoses can be removed from harm's way at the front. There is a Scammell-originated double drive rear bogie, and the truck has just one forward and one reverse gear through its Allison automatic gearbox.

Barnes' ruddy face becomes animated when he talks of his plans for the S24, and it is with the air of an aficionado that he claims "bonnets are beautiful". Unipower will manufacture the S24 in various forms to increase its appeal in the specialist market. There are plans to move its weights up and down, and the range of power units will vary from 205kW (275hp), 373kW (500hp), and more.

By using the experience of his staff, Barnes hopes to sell limited numbers of the bonneted S24 in 4x2, 6x4, and 6x6 versions to specialist operations like that at Llanwern Steel Works. Although the heavy haulage sector will be canvassed for trade, Barnes does not think it will supply a great number of orders. For the moment, Unipower's biggest customer will be the Ministry of Defence, with orders for the ex-Scarnmell Commander, and crash tenders.

SIDE BY SIDE

The ex-Scammell and the Unipower crash tenders will continue to be manufactured side by side. Eight ex-Scammell crash tenders will be laid down in January, selling to the MoD. Barnes forecasts an eventual move towards a combined Unipower crash tender range, but the current orders from the MoD have considerably helped Unipower's turnover. The exScarnmell operation will probably double the Group's turnover to around £10 million during this financial year.

It is always difficult to get a clear view in the crystal ball of a company's success potential — just ask the Department of Trade and Industry. Unipower, however, doesn't have to try too hard with its vehicle building because the parts department should provide a basis of regular income from which to work.

The major contest between AWL), Unipower, and possibly others, for the MoD's Tank Transporter contract has yet to come, but Unipower at least has a "proven product" and, despite its size, the little firm should be battling along with the best of them.

Barnes is adamant that his firm's size is "a great virtue". "We are so small and enthusiastic," he says, "that anyone who comes here is going to get good value for money". Although few firms will be worried about a rival the size of Unipower, Barnes seems serious in his intentions, and asserts that "this is not just a paper exercise".

As the few staff assemble for the photograph round the steelworks-bound S24, Barnes looks round the half-assembled axles, partly completed parts bins, and then back at the "magnificent 25".

"We'll give them a good run for their money, I hope," he says.

0 by Andrew English.