SIMPLE MECHANICS

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

SUSPENSION, 4

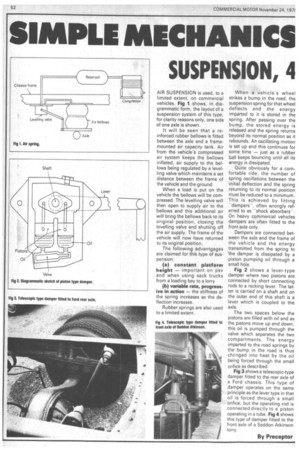

AIR SUSPENSION is used, to a limited extent, on commercial vehicles. Fig 1 shows, in diagrammatic form, the layout of a suspension system of this type; for clarity reasons only, one side of one axle is shown.

It will be seen that a reinforced rubber bellows is fitted between the axle and a framemounted air capacity tank. Air from the vehicle's compressed air system keeps the bellows inflated, air supply to the bellows being regulated by a levelling valve which maintains a set distance between the frame of the vehicle and the ground.

When a load is put on the vehicle the bellows will be compressed. The levelling valve will then open to supply air to the bellows and this additional air will bring the bellows back to its original position, closing the levelling valve and shutting off the air supply. The frame of the vehicle will now have returned to its original position.

The following advantgages are claimed for this type of suspension: (a) constant platform height — important on psv and when using sack trucks from a loading bay to a lorry (b) variable rate, progressive in action — the stiffness of the spring increases as the deflection increases.

Rubber springs are also used to a limited extent. When a vehicle's wheel strikes a bump in the road, the suspension spring for that wheel deflects and the energy imparted to it is stored in the spring. After passing over the bump, the stored energy is released and the spring returns beyond its normal position as it rebounds. An oscillating motion is set up and this continues for some time — just as a rubber ball keeps bouncing until all its energy is dissipated.

Quite obviously for a comfortable ride, the number of spring oscillations between the initial deflection and the spring returning to its normal position must be reduced to a minimum.

This is achieved by fitting "dampers", often wrongly ref erred to as "shock absorbers". On heavy commercial vehicles dampers are often fitted to the front axle only.

Dampers are connected between the axle and the frame of the vehicle and the energy transmitted from the spring to the damper is dissipated by a piston pumping oil through a small hole.

Fig 2 shows a lever-type damper where two pistons are connected by short connecting rods to a rocking lever. The latter is carried on a shaft and on the outer end of this shaft is a lever which is coupled to the axle.

The two spaces below the pistons are filled with oil and as the pistons move up and down, this oil is pumped through the valve which separates the two compartments. The energy imparted to the road springs by the bump in the road is thus chEnged into heat by the oil being forced through the small orifice as described.

Fig 3 shows a telescopic-type damper fitted to the rear axle of a Ford chassis. This type of damper operates on the same principle as the lever type in that oil is forced through a small orifice, but the operating rod is connected directly to a piston operating in a tube. Fig 4 shows this type of damper fitted to the front axle of a Seddon Atkinson lorry.

By Preceptor