A TIDY PAC LAG

Page 50

Page 51

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

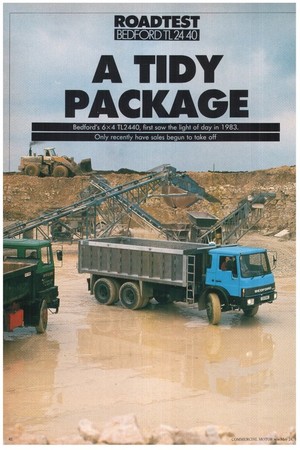

Bedford's 6x4 112440, first saw the light of day in 1983.

Only recently have sales be.un to take off

In recent months much attention has ised on Bedford's poor trading per-nance.

lilt Bedford has been very successful its hybrid light vans, and there ms every likelihood that its middleght double-drive tipping chassis will )w suit.

'he TL2440 which grosses 24.39 nes is marketed as a lighter and aper alternative to the larger-cabbed 6 x 4.

3 chassis cab form it scales a remarka6,195 kg. This is 400 kg lighter than equivalent Leyland model which comic's a 40 percent lion's share of the :e-axle tipper market and 1,000 to 00 kg less than the Daf 2300 and T: Volvo FL respectively.

'ipper operators might well raise a :zical eyebrow at the IL2440's low b weight, and question its relative :ngths.

leavier machines such as the Daf and vo may give up to one tonne lower load but they and other heavier leis are generally renowned for duray and longevity. Bedford engineers their part, however, are confident . by building the TL 2440 with a hed chassis of S77/2 grade 24.39 ne yield steel, is adequately stressed both tipping and mixer applications. work of an extreme nature, they , there is always the option of the vier TM 6 x 4 chassis_ 'he inverted L-shaped chassis rein:ements on the TL2440 run from just yard of the front springs rear hanger the end of the main rails and are :eti and rivetted outside the original nnel.

DRIVELINE ay components and bracketing items n the TM range are used on the TL wheeler, including the turbocharged -litre 'Blue series' of engine.

'he 8.2/210 TD as it is known, was ;Many developed for the military TM 4 I but is also used on 24 to 32.5 tonne GCW IL tractive units.

The engine is probably at its liveliest where its 156kW (208hp) at 2,500rpm provides a healthy 6. 5kW tonne (8.7hp/ton) power-to-weight ratio that is well in excess of the 4.4kW/tonne (6.0hp/ton) minimum legal requirement.

Irrespective of road conditions, the engine's broad 1,200-1,800rpm torque band helped produce a smooth, yet lively, performance and complemented the slick gear selection of the Fuller RTX 6609 nine-speed constant mesh gearbox.

Although there are three gearboxes to choose from, the standard unit as fitted on the test vehicle is the Fuller vrx 6609 nine-speed constant mesh box. This range-change transmission, with its 0.73:1 overdrive top, is matched to the 6.50:1 Eaton 401 DS/DR bogie axles. Using 11R 22.5 tyres, they allow a theoretical top speed of 99.8m/h (62.0mph); but with govenor run-out, the actual maximum speed was about 8% faster at 106km/h (67mph). A direct top Fuller RT6609 box is also available with the 6.50:1 axles. Operators may instead prefer a ZF S6-65 six speed direct top synchromesh unit which, together with the RT6609, is available for the lower (numerically) 4:88:1 final drives.

The major difference between them lies not so much in their relative maximum speeds which vary by only 3.2km/h (2.0mph) but in their gradeability.

Where the test vehicle with its RTX 6609 box and 6.55:1 axles had a 99.8km/ (62mph) maximum speed, its hill climbing ability is given as 27% (1 in 3.7). This would be slightly more suitable for working out of deep quarries and over hilly terrains than the ZF box with its 4.88:1 rear axles which have a 96km/h (60mph) top speed and a 22% (1 in 4.5) gradeability.

There is an immediate bonus in choosing a synchromesh unit. This is not so much in reduced clutch operation, but a reduction in the list price by V126.

Whatever transmission is specified, it will drive through a Spicer ceramic-faced single-plate clutch, which is now fitted in preference to the twin-plate arrangement, with traditional organic linings.

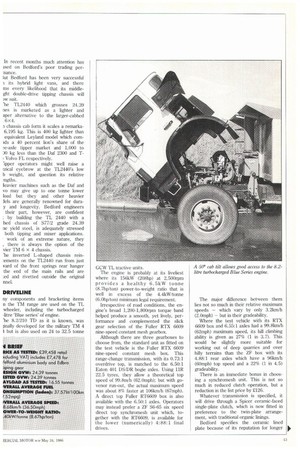

Bedford specifies the ceramic lined plate because of its reputation for longer life and durability. There has also been minor changes to the clutch actuation, which now uses a pull-type arrangement with the air chamber mounted on the left hand side of the gearbox.

On the MIRA test hills the 6 x 4 showed that there is no difference in performance between the two types of plate, apart from being insensitive as the drive is taken up.

Using crawler gear, the TL2440 showed that it could achieve its 27% gra&ability rating by pulling away quite easily from the 25% (1 in 4) test hill.

• PERFORMANCE Achieving sharp acceleration figures proved to be well within this vehicle's capability too, as the track test results illustrate.

The Bedford 6 x 4's times from 0 to 48krii/h (0.30mph) kept pace with the Perkins V8-powered Dodge G24 (CM July 27,85) but could not sustain it beyond. From 0-801cm/h (0-50mph), however, it showed a clean pair of heels to Leyland's

24.21 Constructor with its TL11A (CM May 4, 85) in a time that was 30 seconds faster.

On the roads the 6 x 4 proved to be capable of keeping up with fast-flowing traffic, especially through built-up areas.

Starting off from traffic lights on the flat required only second and fourth in the low range, followed by sixth, seventh, and then top. Only on the sharper climbs was it necessary to use first gear to move away from rest, with crawler reserved for the severest hill starts.

On the two-stage hill climb at Edge Hill on the A422, the well run-in Fuller RTX/6609 box was helped by the lightlyoperating clutch pedal which allowed for easy skip-shifts.

The sharp 16.5% rise brought it quickly down to third low, where another half gear would have sufficed. In fact, it was necessary to drop a further gear to second and ease off the pedal, before climbing at 12km/h (7mph) at about 1,800rpm with power to spare.

On the TL2440, Bedford fits a fixed, six

bladed fan, in case a front-mounted pt-o needed; but this might have been betl as an option with a thermostatical controlled device as standard, to cutpower losses slightly. Not that it had a ill-effect when working so hard, as t temperature gauge climbed no furth than midway, at around 90°C.

While the weather during the two da trial brought showers, there was ye little wind throughout, and traffic w quite light for what was the first sl wheeler around our new tipper route.

There can be no cross-comparisions t tween results on this and the origii route. Previously, there had been motorway running but a deal more off-ro work involved.

However, the TL2440 performance especially over the A-road section seemed very favourable. Here it turned its best figures of 35.1 lit/1001 (8.05mpg) at an average speed 54.0km/h (33.60mph).

Despite the contraflow plague on t Ml, the 6 x 4 produced a fairly qui

65km/h (50.75mph) average speed on motorway section, which was on a par :h the LT-250 powered Seddon Atkin, 8x4 tested last week. Running at the km/h (60mph) limit helped to bring the E!rall figures down to 37.61it/100km 52mpg) fuel consumption at 58.71km/h i.5mph).

HANDLING

idulating roads highlighted a softness at front end where the two-leaf, semitic springs allowed a tendancy to dip mewhat. But, generally, they combined 1 with the Norde rubber suspension at 1, rear.

Over rough site roads especially, the 6 4 gave a stable, well-controlled ride d handled well. For manoeuvrability, 1'L2440, with its Cam Gears powerRisted steering, scores highly.

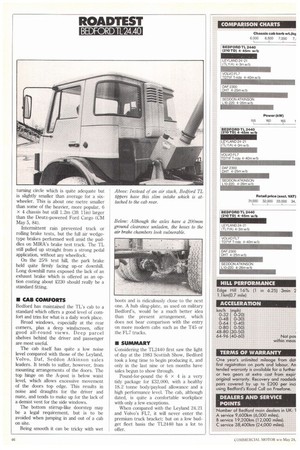

Whether in a busy site such as Smith d Sons quarry at Ardley Fields, or in a ngested town road, the TL is easy to turning circle which is quite adequate but is slightly smaller than average for a sixwheeler. This is about one metre smaller than some of the heavier, more popular, 6 x 4 chassis but still 1.2m (3ft llin) larger than the Deutz-powered Ford Cargo (CM May 5, 84).

Intermittent rain prevented track or rolling brake tests, but the full air wedgetype brakes performed well amid the puddles on MIRA's brake test track. The TL still pulled up straight from a strong pedal application, without any wheellock.

On the 25% test hill, the park brake held quite firmly facing up-or downhill. Long downhill runs exposed the lack of an exhaust brake which is offered as an option costing about £230 should really be a standard fitting.

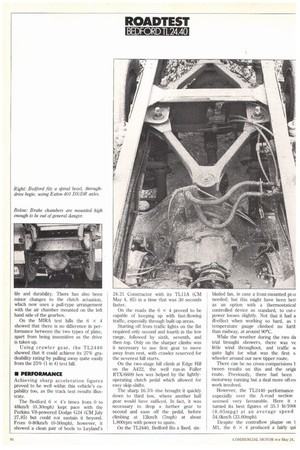

• CAB COMFORTS

Bedford has maintained the TL's cab to a standard which offers a good level of comfort and trim for what is a daily work place.

Broad windows, especially at the rear corners, plus a deep windscreen, offer good all-round views. Deep parcel shelves behind the driver and passenger are most useful.

The cab itself has quite a low noise level compared with those of the Leyland, Volvo, Daf, Seddon Atkinson sales leaders. It tends to suffer, however, from mounting arrangements of the doors. The top hinge on the A-post is below waist level, which allows excessive movement of the doors top edge. This results in noise and draughts for the driver and mate, and tends to make up for the lack of a demist vent for the side windows.

The bottom stirrup-like doorstep may be a legal requirement, but is to be avoided when jumping in and out of a cab on site.

Being smooth it can be tricky with wet boots and is ridiculously close to the next one. A hub sling-plate, as used on military Bedford's, would be a much better idea than the present arrangement, which does not bear comparison with the entry on more modern cabs such as the T45 or the FL7 trucks.

• SUMMARY

Considering the TL2440 first saw the light of day at the 1983 Scottish Show, Bedford took a long time to begin producing it, and only in the last nine or ten months have sales begun to show through.

Pound-for-pound the 6 x 4 is a very tidy package for £32,000, with a healthy 18.2 tonne body/payload allowance and a high performance level. The cab, although dated, is quite a comfortable workplace with only a few exceptions.

When compared with the Leyland 24.21 and Volvo's FL7, it will never enter the premium truck bracket; but on a low budget fleet basis the TL2440 has a lot to offer.