EIGHT WHEELER VARIATIONS

Page 35

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

Crowded as ever, Harrogate's exhibition centre was a popular venue for Tipcon visitors

• Harrogate's exhibition centre was as crowded as ever with vehicles and equipment on display for Tipcon, with several important vehicles having to pose outside.

New eight-wheelers were a feature of this year's show — or rather new versions of eight-wheelers were. Iveco had its new 300.25. This has the more modern look of the 'total efficiency concept' Iveco haulage vehicles, but retains the distinctive Deutz aircooled V8 engine of the old 'Maggie'. If anything, the bigger, slower-revving F8L513 engine has an even more distinctive engine noise. The cab is a definite improvement over the old Ulm one, and to prove the point, Iveco had a seven-year-old example of a 300.23 on its stand. This had covered 750,000km in the hands of Duggie Oxborough, hauling an estimated 175,000 tonnes of sand in that distance on its original engine and gearbox.

MAN has taken the lead in the power race for tippers by fitting its 246kW (33011p) Formula 6S engine to its eightwheeler to produce the 30.331. The vast amount of power and torque available is reflected in the re-gearing of this truck. It pulls a 4.2:1 rear axle ratio, compared with the 4.77:1 in the lower-powered 30.291. The big model is officially available to special order only. although seven had been sold before the show. The 30.331 has the Fuller 13speed Roadranger gearbox, and has a list-price premium of around £1,000 over the lowerpowered versions.

Hino's distributor has finally

got the 8x 4 tipper chassis type-approved, and the 6x4 followed two weeks ago. The company says that 32 of the 8 x4s (priced at £41,000) are on the road already, and it expects to sell up to 80 this year. The sales target for the 234,500 6x4 is higher at 90 units.

Fuel consumption is the single largest operational cost. Now for about 21,350, Swiss instrument maker Flowtronic will provide a package, containing a heat exchanger, that will allow the engineer to readily

check the performance of any vehicle in his fleet.

Bedford has its tiny Rascal tipper as a drawcard — lip. master's adaptation of the standard factory dropside body into a tipper using electro-hydraulic power and a four-stage ram is certainly tidy. The newest thing in the larger Bedford ranges was the paint job on the TL 6 x 4. When CM tested this self-same vehicle for this week's issue it was painted bright blue, but it appeared in Harrogate in a wellknown shade of yellow.

The ubiquitous Cummins L10 engine has found its way into Ford's 6x4 Cargo tipper chassis, in 181kW (240hp) form. This makes it Ford's most powerful tipper ever (unless somebody starts fitting tipping trailers to the more powerful Cummins-engined tractors). Although long-wheelbase versions of the new Transit are not yet available, there was a Transit tipper in Cross colours on the Ford stand.

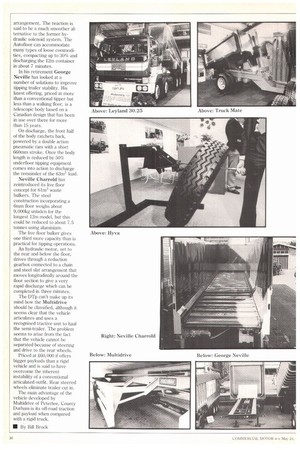

Leyland claims about 530 of the total 2,000 eight leggers sold in the UK each year but less than 10% of these are fitted with the company's own TL11C power units. Rolls Royce remains the most popular, followed closely by Cummins while Gardner is a long way behind accounting for just over 10%.

Tipcon was the first occasion on which Volvo has been able to show tipper versions of each of the FL6, FL7 and FL10 together. High point of the stand was the 6x4 FL7 which was the 5,000th Volvo to be sold by Yorkshire distributor Crossroads Commercials, since it started selling Volvos in November 1967.

Terberg, sold through Volvo in the UK, is still using the old range of cabs, but will be introducing Volvo's new FL6 cab and a turbocharged 10-litre en

gine on some fourand six-all wheel drive models later in the year.

At about the same time the company will bring in a fiveaxle rigid 10x8 using the F10/12 cab. Terberg hubroduction is used for the first and second axles; the third also with 10 tonne capacity is steered but not driven, while the fourth and fifth hub reduction axles are rated at 15 tonnes each.

The Truck Mate system designed by HCW Gaye gives an extension to the payload capacity of six and eight wheeled chassis without any road tax disadvantages.

Priced at £4,200 plus the body, the single-axle draw-bar trailer can take a 7.5 tonne payload. It is believed to be the first application using the Norde Fluidride suspension on a single axle.

Southworth demonstrated the benefit that can be gained by adding an extra axle to a 16 tonner.

Besides improving the ride, taxation class may be changed to that of a 21-tonner with three axles, saving £370 on road tax but with an extra 4 tonne carrying capacity. .

Where the plated weight is increased to 23 tons, there is an annual saving of 710 on the charge for a 24-tonner, though with the loss of 1 ton in payload, but with the possibility of recouping the installation costs several times over during the life of the vehicle.

Hyva is marketing a spare wheel carrier that removes all of the lifting associated with changing a spare wheel.

When it is released from its clamp, it is allowed to drop to an inclined position ready to be rolled away. To reposition a spare wheel the procedure is reversed so that, first using a bar, the wheel is lifted on to a front catch. From this position it is an easy matter to swing it up to locate and lock at the rear before tightening down with a single retaining nut.

It is sure to save a lot of effort but it is also quick and safe.

A walking floor system is one of three ideas that was demonstrated for the safe discharge of maximum size bulkers. The Wilcox design looked very little different from others that we have seen over recent years. That is until we examined beneath the moving slats to find that the sequence of movement is determined by an electric switching

arrangement. The reaction is said to be a much smoother alternative to the former hydraulic solenoid system. The Autofloor can accommodate many types of loose commodities, compacting up to 30% and discharging the 12m container in about 7 minutes.

In his retirement George Neville has looked at a

number of solutions to improve tipping trailer stability. His latest offering, priced at more than a conventional tipper but less than a walking floor, is a telescopic body based on a Canadian design that has been in use over there for more than 15 years.

On discharge, the front half of the body ratchets back, powered by a double action pneumatic ram with a short 660mm stroke. Once the body length is reduced by 50% underfloor tipping equipment comes into action to discharge the remainder of the 63m3 load.

Neville Charrold has reintroduced its live floor concept for 61m3 waste bulkers. The steel

construction incorporating a 6mm floor weighs about 9,000kg unladen for the longest 12m model, but this could be reduced to about 7.5 tonnes using aluminium.

The live floor bulker gives one third more capacity than is practical for tipping operations.

An hydraulic motor, set to the rear and below the floor, drives through a reduction gearbox connected to a chain and steel slat arrangement that moves longitudinally around the floor section to give a very rapid discharge which can be completed in three minutes.

The Dip can't make up its mind how the Multidrive should be classified, although it seems clear that the vehicle articulates and uses a recognised tractive unit to haul the semi-trailer. The problem seems to arise from the fact that the vehicle cannot be separated because of steering and drive to the rear wheels.

Priced at £60,000 if offers bigger payloads than a rigid vehicle and is said to have overcome the inherent instability of a conventional articulated outfit. Rear steered wheels eliminate trailer cut in.

The.main advantage of the vehicle developed by Multidrive of Peterlee, County Durham is its off-road traction and payload when compared with a rigid truck.

By Bill Brock