Countless Urn ral Features in

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

A NEW BRITI. [ OIL TANKER

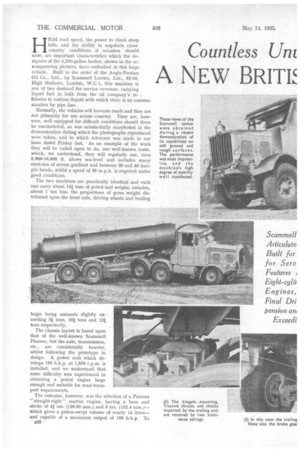

HIGH road speed, the power to climb steep hills, and the ability to negotiate crosscountry conditions if occasion should arise, are important characteristics which the designers of the 4,200-gallon tanker, shown in the ac

companying pictures, have embodied in this huge vehicle. Built to the order of the Anglo-Persian Oil Co., Ltd., by Scammell Lorries, Ltd., 52-59, High Holborn, London, W.C.1, this machine is one of two destined for service overseas, carrying liquid fuel in bulk from the oil company's re—. fineries to various depots with which there is no commurdcation by pipe line.

Normally, the vehicles will traverse roads and they are not primarily for use across country. They are, however, well equipped for difficult conditions should these be encountered, as was satisfactorily manifested in the demonstration during which the photographs reproduced were taken, and to which reference was made in our issue dated Friday last. As an example of the work they will be called upon to do, one well-known route, which, we understand, they will regularly use, rises 8,000-10,000 ft. above sea-level and includes many Stretches of severe gradient and between 30 and 40 hairpin bends, whilst a speed of 35 m.p.h. is required under good conditions.

The two machines are practically identical and each can carry about 141 tons of petrol and weighs, unladen, -about 1 ton less, the proportions of gross weight distributed upon the front axle, driving wheels and trailing

bogie being amounts slightly exceeding 3 tons, lot tons and 12i tons respectively.

The chassis layout is based upon that of the well-known Scammell Pioneer, but the axle, transmission, etc., are considerably heavier, whilst following the prototype in design. A power unit which develops 168 b.h.p. at 1,650 r.p.m. is installed, and we understand that some difficulty was experienced in obtaining a petrol engine large enough and suitable for road-transport requirements.

The outcome, however, was the selection of a Parsons " straight-eight " marine engine, having a bore and stroke of 4iins. (120.65 mm.) and 6 ins. (152.4 mm.)--which gives a piston-swept volume of nearly 14 litres— and capable of a maximum output of 180 b.h.p. To meet the requirements of the new conditions of usage, this power unit was drastically modified, the crankcase, cylinder heads, induction and exhaust systems and auxiliaries being among the components replaced or structurally altered,

Through a standard clutch with springs of increased strength, the crankshaft torque is transmitted to a Pioneer-type five-speed gearbox and thence to a Scammell double-layshalt two-speed box, giving an overdrive in the higher ratio. This is coupled to the fixed bogie axle by a short shaft incorporating two Hardy Spicer needle-roller-bearing universal joints, and the final drive is by trains of spur gears, contained in cases which form rocking beams, to the four driving wheels.

Mounted on the frame above the driving bogie, the kingpin assembly is of special interest. With their four ends housed in boxes, bolted to the frame, in which they are free to slide a limited distance, two leaf springs are arranged transversely across the frame, one behind the other. Between them, at the centre, and supported on a pair of angle-section cross-members, on which it can move in a fore-and-aft direction, is the kingpin socket housing. The pin itself is fixed to the base of the tank, and has a steel ball at its lower end which works in a phosphor-bronze cup.

The length of the pin and its spherical mounting permit universal articulation (of the two units comprising the vehicle), which is limited only by the tank fouling the mudguards or the back of the cab. An angularity in a horizontal plane of 90 degrees is practicable, which gives a turningcircle diameter of under 50 ft. Tractive and overrunning shocks are cushioned by the two transverse springs.

Unlike the Pioneer, which has a centrally pivoted front axle, the machine under present consideration has a new form of forward suspension in which are embodied Gniss air springs made by J. MacDonald and Co. (Pneumatic Tools), Ltd., Pollokshaws, Glasgow.

Mounted on the outsides of the longitudinals, at their front ends, the two air cylinders support, through theirmoving plungers, a floating cross-member, itself carrying the forward ends of the conventional seini-elliptia road springs, to which it is shackled. The trailing bogie follows in general design that used on the standard Scammell New Type eight-wheeler, but differs in that rubber columns are not employed. Instead, there is an inverted semi-elliptic leaf spring on each side, below the two radius arms which govern the movement of the trailing stub axles, the springs being fixed_at their centres to the main cross-member of the bogie superstructure and linked at their ends to the beams , above them. Thus independent movement of each wheel is permitted.

Operated by either a pedal or a hand lever, the main braking system is of the compressed-air type, incorporating the latest Dewandre pressure-servo gear. The master valve controls four air cylinders, one applying the driving-wheel brakes, two the front-wheel brakes, and the fourth the trailing-wheel brakes. The first-named are also mechanically connected to the controls, so that, in the unlikely event of the pressure failing, the four driving wheels can still be used for retardation. In addition, there is a Neate brake, by which the shoes in the trailing-wheel drums can be applied by cable, and a further control lever is mounted below the tank for parking.

Air pressure is created by a two-cylindered watercooled compressor, driven with the engine auxiliaries, and is stored in a 1.7-cubic-ft. tank at the back of the cab. The working pressure is 80 lb. per sq. in.

There are three compartments in the tank, which is a product of Thompson Brothers (Bilston), Ltd. Two of these are for 2,000 gallons each, and one for about 200 gallons. The small compartment is a service tank, provision being made for pumping, by hand, petrol from it to the two 45-gallon tanks, from which a pair of Amal 170-pint-per-hour fuel pumps feeds the two ClaudelHobson down-draught carburetters. The usual tanker equipment—a fire screen, upturned exhaust pipes, etc.— is included.

Within the can, mounted on the dashboard, are a B34 drinking-water and a reserve-lubricating-oil tank. Pro. vision is also made for a man to sleep, lying fore and aft, on the floor of the cab at the near side.

. Marles steering is used and all wheels are shod with Dunlop single 13.50-in. by 20-in. tyres, whilst it is of interest that the tank portion of the outfit can readily be detached from the tractive unit. There is a power takeoff on the main gearbox for driving a winch or other apparatus.

Reverting to the power unit, this is mounted in a subframe rigidly carried at three points on the main frame. Its eight cylinders are cast in pairs, and the heads, which give a compression ratio of 4.8 to 1, as previously mentioned, are of Scammell design. This also applies to the base, whilst the top half of the crankcase has been cast in aluminium to replace the heavier metal originally employed. It has doors on both sides to give access to the crankshaft and big-end bearings. There is a torsional vibration damper at the front end, and magneto and coil ignition with separate plugs and distributors are used.

All auxiliaries are mounted in tandem on the near side, being driven from the timing gear, which comprises helical gearing. A feature of the Scammell water pump is the employment of cork spring-loaded glands.

Each carburetter (also the compressor) draws airfrom a huge Visco oil-bath air cleaner, nearly 1 ft.

in diameter. These' are similar in design to that described in connection with the Scammell pipecarrying machine in the issue of The Commercial Motor dated September 28, 1934.

The engine speed is limited by a centrifugal-type governor, which controls the carburetter throttle valves. During experiments, separate

induction pipe governor valves were tried, but the final system showed a gain of -10 b.h.p. There is a balan,ce pipe between the two hotspot induction manifolds, and each group of four cylinders has its own exhaust system.

New exhaust valves have been fitted, and oil is fed under pressure to their stems, , a separate A.C. filter being in cluded in this circuit. The main oil supply is drawn by the plunger pump, driven from the camshaft, through a large gauze filter, no such device, which might cause a restriction, being incorporated in the main circuit on the pressure side of the pump.

To ensure adequate cooling of the power unit during the negotiation of the difficult mountain roads referred to earlier, an extra large Still-tube-type radiator is used, the draught being positively created by a fan working in cowling at the back of the radiator.

The original pistons were replaced by lighter ones of aluminium alloy, with floating gudgeon pins and split skirts, for which the unlined cylinder bores were rehoned. The running of these la,rge engines has been found entirely satisfactory in respect of output, consumption and efficiency, whilst, although electric starters are incorporated, we understand that they will start from cold .011,, the coil-ignition system without fail at the second pull up of the starting handle. The magneto is used alone for normal running.