ARGYLL STORES is a fairly anonymous name but it includes

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

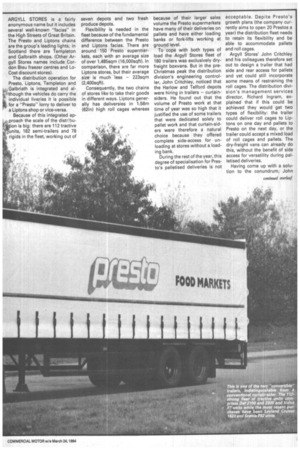

several well-known "facias" in the High Streets of Great Britain. The Presto and Liptons chains are the group's leading lights; in Scotland there are Templeton and Galbraith shops. (Other Argyll Stores names include Cordon Bleu freezer centres and LoCost discount stores).

The distribution operation for Presto, Liptons, Templeton and

1 Galbriath is integrated and al' though the vehicles do carry the individual liveries it is possible for a "Presto" lorry to deliver to a Liptons shop or vice-versa. Because of this integrated ap Otproach the scale of the distr:buion is big: there are 112 tractive „units, 182 semi-trailers and 78 rigids in the fleet, working out of

seven depots and two fresh produce depots.

Flexibility is needed in the fleet because of the fundamental difference between the Presto and Liptons facias. There are around 150 Presto supermarkets, each with an average size of over 1,485sqm (16,000sqft). In comparison, there are far more Liptons stores, but their average size is much less — 223sqm (2,400sqft).

Consequently, the two chains of stores like to take their goods in different ways. Liptons generally has deliversies in 1.58m (62in) high roll cages whereas because of their larger sales volume the Presto supermarkets have many of their deliveries on pallets and have either loading banks or fork-lifts working at ground level.

To cope with both types of load the Argyll Stores fleet of 180 trailers was exclusively dryfreight boxvans. But in the preChristmas peak the distribution division's engineering controller, John Critchley, noticed that the Harlow and Telford depots were hiring in trailers — curtainsiders. He found out that the volume of Presto work at that time of year was so high that it justified the use of some trailers that were dedicated solely to pallet work and that curtain-siders were therefore a natural choice because they offered complete side-access for unloading at stores without a loading bank.

During the rest of the year, this degree of specialisation for Presto's palletised deliveries is not acceptable. Depite Presto's growth plans (the company currently aims to open 20 Prestos a year) the distribution fleet needs to retain its flexibility and be able to accommodate pallets and roll cages.

Argyll Stores' John Critchley and his colleagues therefore set out to design a trailer that had side and rear access for pallets and yet could still incorporate some means of restraining the roll cages. The distribution division's management services director, Richard Ingram, explained that if this could be achieved they would get two types of flexibility: the trailer could deliver roll cages to Liptons on one day and pallets to Presto on the next day, or the trailer could accept a mixed load of roll cages and pallets. The dry-freight vans can already do this, without the benefit of side access for versatility during palletised deliveries.

Having come up with a solution to the conundrum, John Critchley went early in 1983 to York Trailer with his idea. York has built some Argyll trailers in the past and John Critchley felt the company was a particularly suitable choice for the new trailer. "I respect York's engineering skills; they are not just bodybuilders," he said.

York converted John Critchley's idea into the metal and built two trailers to the new design. Argyll Stores put them into service last October just in time for the Christmas rush.

Externally, the new trailer design looks like a conventional 12.2m (40ft) curtain-sider with rear doors and a tail-lift. And when it is used to carry a completely palletised load for a Presto delivery it also functions exactly like a normal curtainsider. There are webbing nets in 3m (10ft) lengths suspended from full-length roof rails set just inside and curtains to provide extra load security for the palletised goods.

But when the trailer is in its roll-cage configuration, pulling the curtain back reveals a removable internal steel frame. At the mid-point along each side there is a fixed vertical sidepost to support the roof structure. In addition, there are two removable posts on each side of the trailer, meaning there are verticals at 3m (10ft) intervals.

Horizontal rails are locked in to run between the posts, 30cm (1ft) and 1.52m (5ft) above the floor. Package Control's Loadlok 1806 tracking lines the inner face of the rails to give anchorage points for the load straps preferred by Argyll Stores because they take up less space than poles.

The strength of the framework is reckoned to give the curtainsider the same degree of load restraint as a dry-freight boxvan. It needs to; the Argyll Stores roll cages average 355-406kg (78cvvt) and their easy mobility works against them when it comes to load restraint.

Inevitably, the framework inside the Argyll trailer reduces its internal width, but since curtainsided bodywork maximises on width in the first place there is still 2.39m (7ft 10in) available, which is similar to the company's dry-freight vans.

The vertical side posts and horizontal rails in the framework are made of box-section steel and John Critchley estimated that they add 0.5-0.75 tonne to the weight. Including the onetonne capacity Ratcliff tail-lift, the trailer tips the scales at around 7.5 tonnes. Fortunately, weight is not a problem with the mixed loads of food products being carried by the Argyll Stores fleet; it is a 32-ton operation with no intention of moving up to 38 tonnes at an early date.

When palletised loads are being carried the framework is, of course, superfluous and the individual posts and rails are stowed in racks built into the trailer's roof structure. In the event of an unusually heavy load such as a complete delivery of canned goods or sugar it would be on pallets and so the framework could be left at the depot if necessary.

If the trailer is to be used to carry a mixture of pallets and roll cages, only the rear 3m (10ft) sections of framework are erected to restrain the roll cages — they need to be at the back so that they can be wheeled onto the tail-lift for unloading.

According to John Critchley, the conversion from pallet to roll-cage configuration or viceversa takes one man about 15 minutes, although he may need assistance when it comes to stowing the side posts in the roof — they are quite a weight to be held at arm's length overhead.

Argyll Stores is also using the two trailers to experiment with a new floor specification. Instead of its usual hardwood with treadplate the trailers have York's Vamel floor, which is plywood with a non-slip glass-reinforced plastic surface.

The two trailers went into service at the depots that had previously hired in curtain-siders at peak times — Telford and Harlow. They are just five months' old now and John Critchley said that their success or otherwise will be reviewed At least no adverse reaction has come back from the depots to the head office in Hayes where he is based, he said. And unlike another supermarket chain that has attempted to introduce a new trailer design, no industrial relations problems had occurred.

As far is John Critchley is concerned from an engineering point of view, the "convertible" trailer has been a success, but he admits it is not perfection If, at the end of the year's assessment the company decides that the principle of a flexible trailer is worth pursuing he has an alternative design that should allow a rather simpler conversion.

In place of the removable separate posts and rails the framework would be hinged from the roof structure and swing down in 1.52m (5ft) long sections. The idea was mooted when the current two trailers were in build last autumn, but the need to get the trailers on the road in time for the Christmas peak dictated the simpler solution. John Critchley also pointed out that the swing-down side sections method would save weight as well since the fairly extensive stowage bracketry in the roof would be eliminated.

In one respect, the two curtain-siders are inferior to the grp dry-freight boxvans; security. It has not been a problem to date, but John Critchley acknowledges that it could be.

The two trailers each cost E14,300, which is more than the dry-freight vans, but also presumably includes a small development cost.

With the planned growth of the Presto chain it is likely that the Argyll Stores distribution fleet will more frequently need pallet-carrying capability with side as well as rear access. But with roll cages still used for the majority of deliveries, a small proportion of the trailer fleet that can accommodate pallets and/or roll cages equally well should be useful.

• by David Wilcox