Hydrostatic drive for Drum cargo pumps

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

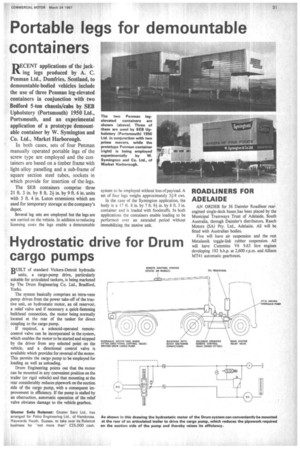

BUILT of standard Vickers-Detroit hydraulic units, a cargo-pump drive, particularly suitable for articulated tankers, is being marketed by The Drum Engineering Co. Ltd., Bradford, Yorks.

The system basically comprises an intra-vane pump driven from the power take-off of the tractive unit, an hydrostatic motor, an oil reservoir, a relief valve and if necessary a quick-fastening bulkhead connection, the motor being normally located at the rear of the tanker for direct coupling to the cargo pump.

If required, a solenoid-operated remotecontrol valve can be incorporated in the system, which enables the motor to be started and stopped by the driver from any selected point on the vehicle, and a directional control valve is available which provides for reversal of the motor. This permits the cargo pump to be employed for loading as well as unloading.

Drum Engineering points out that the motor can be mounted in any convenient position on the trailer (or rigid vehicle) and that mounting at the rear considerably reduces pipework on the suction side of the cargo pump, with a consequent improvement in efficiency. If the pump is stalled by an obstruction, automatic operation of the relief valve obviates damage to the vehicle gearbox.

Gloster Sells Rolamat: Gloster Saro Ltd., has arranged for Pelco Engineering Ltd., of Handcross. Haywards Heath, Sussex, to take over its Rolamat business for "not more than" E25,000 cash.