A Fuel-injection System for Producer and Town-gas Engines

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

The DeIowa Apparatus In Which Gas Under Pressure is Admitted to the Cylinder at the End of the Compression Stroke by a Novel Method

EXPERIMENTS of an interesting and promising nature L. are being conducted by M. Delvaux, Uccle, Brussels. in the development of a new system of introducing fuel into the cylinders of an internal-combustion engine running on town or producer gas. So far, satisfactory results have been obtained with( the former, and there appear good prospects of the principle being successfully applied to the latter.

The scheme is to inject gas, under pressure, into the cylinder at the end of the compression stroke, as is done with liquid fuel in an oil engine.

The advantage of this practice, the inventor states, lies in the fact that if one injects into the cylinder of an engine of the petrol type, which is already full of air, a volume of poor gas, corresponding to the requirements of combustion, the calorific value of the volume of mixture is about 40 per cent, higher than that of a normal cylinder full of air-petrol mixture.

Moreover, the pressure at the end of the explosion is considerably augmented, as the compression, when cold, is virtually double, whilst the volumetric ratio has not been changed. There seems good reason to anticipate, according to M. Delvaux, that it will be possible, with his system, to obtain, on producer gas, an output at least equal to that given with petrol, and to do so without modification of the engine.

With town gas, the fuel is already under pressure, but with producer gas a small compressor would be required. This, of course, would constitute an obstacle, but not an insuperable one on heavy machines.

Not the least ingenious part of the scheme is the use of an oil-engine injection pump to operate the gas injector. Its function, however, is merely to open a valve; no liquid is discharged, the column in the pipe line simply moving backwards and forwards, for a distance dependant upon the angular position of the injection-pump cylinder, and transmitting the motion (or part of it) of the plunger to the stem of the gas inlet valve.

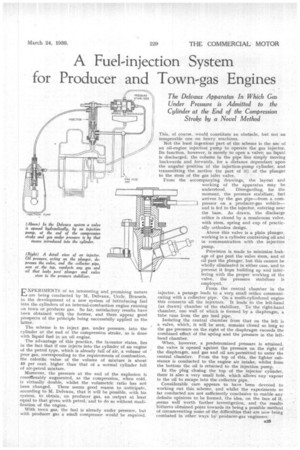

From the accompanying drawings, the layout and working of the apparatus may be understood. Disregarding, for the moment, the pressure stabilizer, fuel arrives by the gas pipe—from a compressor on a producer-gas vehicle— and is fed to the injector, entering near the base. As drawn, the discharge orifice is closed by a mushroom valve, with stem, spring and cup of practically orthodox design.

Above this valve is a plain plunger, working in a cylinder containing oil and in communication with the injection pump.

Provision is made to minimize leakage of gas past the valve stem, and of oil past the plunger, but this cannot be wholly eliminated in either case, and to prevent it frqm building up and interfering with the proper working of the valve, the pressure stabilizer is employed.

From the central chamber in the injector, a passage leads to a very small orifice communicating with a collector pipe. On a multi-cylindered engine this connects all the injectors; It leads to the left-hand (as drawn) chamber of the stabilizer. To the right-hand chamber, one wall of which is formed by a diaphragm, a tube runs from the gas feed pipe.

Isolating the central chamber from that on the left is a valve, which, it will be seen, remains closed so long as the gas pressure on the right of the diaphragm exceeds the combined effect of the spring and the pressure in the lefthand chamber.

When, however, a predetermined pressure is attained, the valve is opened against the pressure on the right of the diaphragm, and gas and oil are permitted to enter the central chamber. From the top of this, the lighter substance is conducted to the engine air intake, whilst from the bottom the oil is returned to the injection pump.

In the plug closing the top of the injector cylinder, there is also a very small hole, which. allows any vapour in the oil to escape into the collector pipe.

Considerable care • appears to have been devoted to working out this scheme, and whilst the experiments so far conducted are not sufficiently conclusive to enable any definite opinions to be formed, the idea, on the face of it, seems well worth further investigation, and the results hitherto obtained point towards its being a possible method of circumventing some of the difficulties that are now being combated in other ways by producer-gas engineers.