Automatic Tailboards on Special purpose Tippers

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

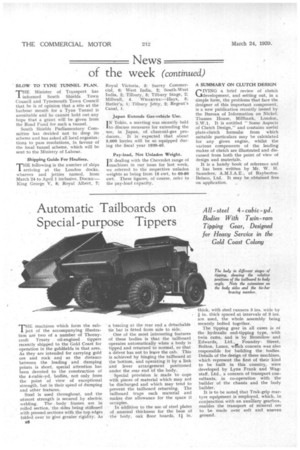

All-steel 4 cubic yd. Bodies With Twin-ram Tipping Gear, Designed for Heavy Service in the

Gold Coast Colony

THE machines which form the sub ject of the accompanying illustration are two of a number of Thornycroft Trusty oil-engined tippers recently shipped to the Gold Coast for operation in the goldfields in that area. As they are intended for carrying gold ore and rock and as the distance between the loading and dumping points is short. special attention has been devoted to the construction of the 4-cubic-yd. bodies, not only from the point of view of exceptional strength, but in their speed of dumping and other features.

Steel is used throughout, and the utmost strength is secured by electric welding. The body frames are in rolled section, the sides being stiffened with pressed sections with the top edges folded over to give greater rigidity. As u8 a bracing at the rear end a detachable tie bar is fitted from side to side.

One of the most interesting features of these bodies is that the tailboard operates automatically when a body is tipped and returned to normal, so that a driver has not to leave the cab. This is achieved by hinging the tailboard at the bottom, and operating it by a link and lever arrangement positioned under the rear end bf the body.

• Special provision is made to cope with pieces of material which may not be discharged and which may tend to prevent the tailboard returning. The tailboard traps such material and makes due allowance for the space it occupies.

In addition to the use of steel plates of unusual thickness for the base of the body, oak floor boards, 1i in. thick, with steel runners 3 ins, wide by in. thick spaced at intervals of 3 ins. are used, the whole assembly being securely bolted together.

The tipping gear in all cases is of the hydraulic end-tipping type, with twin rams, and is by Bromilow and Edwards, Ltd. Foundry Street, Bolton, Lanes, NI:rich concern was also responsible for building the bodies. Details of the design of these machines, which represent the first of their kind to be built in this country, were developed by Lyne Frank and Wagstaff, Ltd., a concern of transport consultants, in co-operation with the builder of the chassis and the body builder.

It is to be noted that Trak-grip reartyre equipment is employed, which, in conjunction with an auxiliary gearbox, enables the transport of mineral ore to be made over soft and uneven ground.