INTERNATIONAL IOADSTAR 1100/YORK ARTIC

Page 70

Page 71

Page 72

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

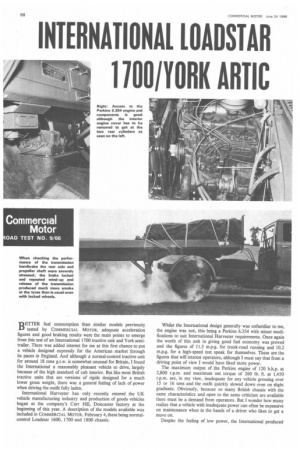

BETTER fuel consumption than similar models previously, tested by COMMERCIAL MOTOR, adequate acceleration figures and good braking results were the main points to emerge from this test of an International 1700 tractive unit and York semitrailer. There was added interest for me at this first chance to put a vehicle designed expressly for the American market through its paces in England. And although a normal-control tractive unit for around 18 tons g.t.w. is somewhat unusual for Britain, I found the International a reasonably pleasant vehicle to drive, largely because of the high standard of cab interior. But like most British tractive units that are versions of rigids designed for a much lower gross weight, there was a general feeling of lack of power when driving the outfit fully laden.

International Harvester has only recently entered the UK vehicle manufacturing industry and production of goods vehicles began at the company's Carr Hill, Doncaster factory at the beginning of this year. A description of the models available was included in COMMERCIAL MOTOR, February 4, these being normalcontrol Loadstar 1600, 1700 and 1800 chassis.

Whilst the International design generally was unfamiliar to me, the engine was not, this being a Perkins 6.354 with minor modifications to suit International Harvester requirements. Once again the worth of this unit in giving good fuel economy was proved and the figures of 11.5 m.p.g. for trunk-road running and 10.2 m.p.g. for a high-speed test speak for themselves. These are the figures that will interest operators, although I must say that from a driving point of view I would have liked more power.

The maximum output of the Perkins engine of 120 b.h.p. at 2,800 r.p.m. and maximum net torque of 260 lb. ft. at 1,450 r.p.m. are, in my view, inadequate for any vehicle grossing over 15 or 16 tons and the outfit quickly slowed down even on slight gradients. Obviously, because so many British chassis with the same characteristics and open to the same criticism are available there must be a demand from operators. But I wonder how many realize that a vehicle with inadequate power can often be expensive on maintenance when in the hands of a driver who likes to get a move on.

Despite the feeling of low power, the International produced acceleration times than all except one of the similar vehicles by COMMERCIAL ,MOTOR in the past two or three years. :asy change which was a feature of the five-speed synchrogearbox helped in this, but only after second gear, as the ;e from first to second was difficult when the first tests were d out. This was later found to be because of the need for slight clutch adjustment and after this the gear change was ;ood.

is hanging on of the clutch probably was also the reason for le difficulty experienced in the early tests with the ratio ;e in the two-speed axle. It was thought at first that this was d by newness as the vehicle tested had completed only a little than 200 miles when I first took it over, but there was again provement after clutch adjustment.

e Loadstars in production at Doncaster are built to a fairly specification, and although two V8 petrol engines with out1 180 and 182 b.h.p. net are listed as options these are con:d more applicable for export. The five-speed gearbox in the ehicle is standard, an option being a four-speed unit. The two-speed axle is, however, an option to the standard single speed. Like most of the mechanical components for the model, this is an import from America, it being of Eaton manufacture and different from the same design (18802) made by the British subsidiary of Eaton Axles only in respect of the differential bevel gears.

Another way in which the test chassis differed from the standard was in respect of braking, the air-assisted hydraulic system replacing the usual vacuum-assisted layout. All the tests on the International were carried out in the area south and west of Doncaster and the load consisted of steel farm-tractor wheel weights placed on the semi-trailer platform to give the desired (and designed) weight distribution. The actual figures can be seen in the specification panel and it was surprising that even with a 21 in. fifth-wheel position (forward of the rear axle centre line) the front axle was carrying only 2 tons 18 cwt. This did not make the steering feel excessively light but it was more than likely the reason for a feeling of vagueness in certain conditions. • The American Ross steering gear used by International gives a variable ratio of 24 to 1 in the straight-ahead position going up to 28 to 1 at full lock. This is fairly low gearing by normal British standards and could have been another reason for the vagueness. But whatever the cause there was a need for fairly continuous correction of the steering to maintain a straight line, particularly when running at high speed on the Doncaster by-pass.

First tests carried out were on the brakes and very good figures were obtained. But I believe they could have been better as there was a fair amount of evidence that the liners were far from bedded in to the drums. On most of the maximum-pressure stops there was some marking of the road by tyres, generally heavy. The position at which the locking occurred varied a good deal and whilst the offside driving wheel locked on all except one of the stops from 30 m.p.h., on one stop from 20 m.p.h. both driving wheels locked and on another the front wheels as well as the offside wheels locked. At no time did the semi-trailer wheels lock and on one of the stops from 30 m.p.h. there were slight marks only from the tractive unit driving wheels.

The road used for the tests was the old Al south of Bawtry and the outfit was completely stable on all the stops despite the variation in effort at the wheels that was apparent. The vehicle was also quite stable on the tests of the transmission handbrake, which produced surprising results with the unit locking both driving wheels immediately it was applied and the outfit bucking considerably and coming to rest in a cloud of smoke from the tyres. Applying a transmission brake from 20 m.p.h. is a very harsh way of treating the rear axle and propeller shaft on an artic grossing over 18 tons, but no trouble was experienced and the excellent Tapley meter reading of 52 per cent was obtained. As already stated, acceleration figures were well up to the standard of similar-design artics. Through-the-gears runs were made with the lower ratio engaged in the rear axle and so were the directdrive tests. On the latter, the Loadstar was not very happy at speeds below about 12 m.p.h., but from this point it pulled away quite steadily.

Still using the old Al, normal-speed fuel consumption tests were carried out on a 12.6 mile out-and-return run from a point north of Bawtry up to the roundabout at Doncaster racecourse and back. The figures of 11.8 m.p.g. fully laden and 17.9 m.p.g. unladen obtained on the two runs there were very good indeed and calculating the consumption that would be obtained on the vehicle running laden one way and empty return (from the actual fuel used) gives a figure of 14.2 m.p.g. A 12.5 mile out-and-return route over the northern end of the Doncaster by-pass was the scene of the high-speed consumption runs and the figures of 10.2 m.p.g. and 13.4 m.p.g. for laden and unladen tests respectively were equally impressive. When running unladen the average speed for the high-speed run increased by 11.1 m.p.h., which gives a good indication of the effect of a low power-to-weight ratio.

The high-speed laden consumption run was carried out in rain and there was a good deal of traffic on the by-pass at the time. Because of the steering characteristics already mentioned I was somewhat uneasy at driving the outfit at its maximum speed of about 57 m.p.h. (where possible) but this had to be done if the test was to have any value.

The light front axle loading and low-geared steering have been suggested as the reason for the way the outfit behaved, but control of the vehicle was very delicate when overtaking on the by-pass and a reason for this could have been the slope of the semi-trailer platform (and the rubbing plate) coupled with some stiffness in the York fifth-wheel spindles. It was also noted when the outfit was uncoupled that the fifth-wheel plate had some high spots.

When on the Doncaster by-pass later in the day maximum speeds in the gear were checked and these were found to be 7, 12, 20,33 and 45 m.p.h. in low axle ratio and 9, 16, 26, 48 and 57 m.p.h. in high axle ratio. These figures take into account a speedometer Iccuracy of 4 per cent fast at 30 m.p.h. and 6 per cent fast at aximurn speed.

There are no reilly good hills in the Doncaster area for gradientrformance tests and two places had to be used-the hill going out -Wentbridge for hill climbing and brake fade and a very minor ad just south of Maltby for hill starts and handbrake tests. The 1 at Wentbridge is 0.5 miles long and has an average gradient of in 12. A maximum-power ascent was made in 2 min. 59 sec., of tich 35 sec. were spent in second/low, the. lowest used, and the inirnum speed was 7 m.p.h. During the climb the temperature of Ater in the engine cooling system had risen from 72°C (162°F) the bottom to 80°C (176°F) at the top. Ambient temperature at e time was 22°C (72°F).

Turning round at the top of the hill, the 0.5-mile descent was made neutral with the footbrake applied to restrict the speed of the outfit 20 m.p.h. At the end of the run, which had lasted 1 min. 24 sec., maximum-pressure stop from 20 m.p.h. gave a Tapley meter ading of 46 per cent compared with 74 per cent on the earlier coldurn test. The tractive unit front brakes and the semi-trailer brakes ere smoking well at the end of the test, which was a little surprising ter such a short run, and the drop in efficiency was more than! pected. Much of the reduction was caused by drum expansion, ident through increased pedal travel.

lain points of eriticism The main points of criticism on the model tested from a driver's rint of view are low power and below-standard steering when den. The advantages for operators of the vehicle are evident from e results and drivers will find a lot to praise in the design. Before ing on to these I would say that! was not satisfied with the mirror cation. The mirrors themselves were large enough-although! mild have preferred convex glasses instead of flat-but the arms which they were mounted did not place them far enough away 3rn the driver to give a view down the sides of the semi-trailer. Most drivers agree that a view of the semi-trailer wheels and end 7 the platform are essential and I got a little improvement by visting the mirrors through 90° on their brackets, but this was not ally enough. Although a platform semi-trailer, visibility to the rear the test outfit was completely dependent on the mirrors because the low height of the International cab. This makes a change in e mirror arms essential if the tractive unit is to be used with 8ft.ide semi-trailers.

The International cab used on the Loadstar is a very well-made lit indeed and the comfort given the driver will be gratefully ceived. The windscreen is relatively shallow, but this did not ake for inadequate forward visibility. Access to the cab is very easy and the interior is well finished.

Instruments are provided rather than warning lights. There is an ammeter, oil-pressure gauge, water-temperature gauge, fuel gauge and air-pressure gauge as well as the speedometer. And as well as the air-pressure gauge reading the driver is warned of low pressure by a flashing indicator and audible alarm. All controls are within easy reach and the brake and clutch are light to operate. A very good ride was given by the suspension in both the laden and unladen conditions, although there was a tendency to bounciness on some road surfaces. Dampers were not fitted on the test vehicle and perhaps the incorporation of this option would have made for an improvement.

Other features of the cab are wind-down windows and opening quarter lights, a fully lined interior, cab light and sun visor, and there is a central ashtray on the facia. On the passenger side (a threeman bench seat is standard) there is a cubby box, and easily accessible in this is a panel containing fuses of the 12 electrical circuits-all well marked.

One advantage of normal-control layout is that normally there is a reduction in engine noise and there is improved access to the engine and components. The International was not noticeably quieter than many of the latest trucks available in the UK when at high speed and laden, but the vehicle was very quiet compared with some old designs. The rear, of the engine protrudes partly into the cab and access to the two rear injectors and so on is by removing a small interior cover.

Basic price of the Loadstar 1700 tractive unit tested is £1,593. Options fitted to the test vehicle with prices are: frame reinforcements, £26; air/hydraulic brakes, £81; two-speed axle. £190; heater, £21; and 9.00-20 Tyres (in place of the standard 8.25-20),39.