Fit Jakes and

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

save on brakes

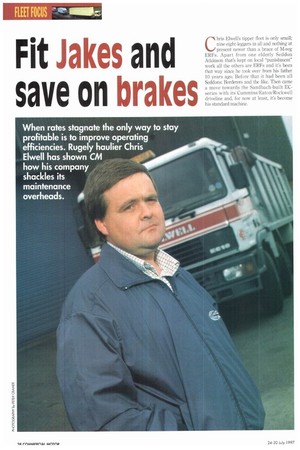

Chris Elwell's tipper fleet is only small; nine eight-leggers in all and nothing at present newer than a brace of M-reg EREs, Apart from one elderly Seddon Atkinson that's kept on local "punishment" work all the others are ERFs and it's been that way since he took over from his father 10 years ago, Before that it had been all Seddons: Borderers and the like. Then came a move towards the Sandbach-built ECseries with its Cummins/Eaton/Rockwell driveline and, for now at least, it's become his standard machine.

But throughout a decade in which fuel costs, VED and wage costs have soared, the quarries' delivery rates have been firmly pegged. It's a dilemma that has pulled many companies apart but Elwell has taken a positive approach in a bid to improve his own operating efficiencies.

His vehicles are specified with the utmost care, and with a wealth of Cummins-user experience he's followed his instincts and gone nap on Jacob's engine brake.

These were factory-fits on his last new tipper purchases—two Ms and an L-reg; the remainder were retrofitted in the Elwell workshop.

Jake's have been around for many years. They fit between the valves and the rockers and work by altering the diesel engine's exhaust valve operation, temporarily converting it into a power-absorbing compressor to produce a retarding effect at the drive axle. To prevent the engine from stalling, a cut-off switch prevents its use below 900rpm.

Being aware of the hazards on today's overcrowded roads, Elwell added the engine brakes as much for driver safety as for its promised maintenance benefits.

His tippers regularly collect aggregates from quarries in deepest Derbyshire and run over hilly roads in the Leek, Buxton, Matlock triangle which is tough on trucks and drivers alike. Descending some of the worst hills, says Elwell, a Jake will hold a laden ERF in third or fourth gear, leaving the service brake cool and fresh should a serious dab on the pedal be needed.

He's full of praise for his drivers, some of whom have been with him for nearly 15 years, and the way that they've taken to the engine brake. That gives Elwell peace of mind. "Think on—when your wagons leave the depot they're outside your control."

There's little to go wrong with the Jake, apart from checking it over visually during periodic engine maintenance. It only needs touching when valves and injectors are serviced every 12 months or at 90,000km.

CM caught up with one of Elwell's newer ERFs at Cummins Diesel, West Bromwich where it was undergoing an annual checkover. True to form, the Jake needed scant attention although the owner kindly agreed to CD West Brom' showing CM the simplicity of the installation and the test checks.

Having fitted Jake brakes across the fleet,

Elwell is monitoring them carefully but already he's certain that they offer material benefits.

Previously his wagons were having a full brake reline every six months, which worked out at around £650 a time plus labour. And every fourth or fifth reline they needed new drums, too, at £100 apiece.

His newest L-reg tipper has just passed the third year mark and has had its first front axle brake relines. "There's still the original paint on the drums," says Elwell, "so clearly the brakes remain cool." He's impressed with the greatly extended brake life and believes the pay-back on the initial £1,500 fitting cost takes around 18 months.

Any investment in tipping has to be costeffective but items such as on-board weighers and aluminium wheels have become the norm and all eight EC10-325s have them. His newest ERFs can carry 21tonne payloads, and the PM weighers enable the drivers to load right up to capacity.

Such money-saving moves are what keeps the company afloat, says Elwell: "We're keyed into the construction industry and when it stops or slows for whatever reason, so does tipper work."

So he's hesitant to lash out on expensive roll-over body covers when be can make his own. All the necessary materials are bought locally, the body end sections are fabricated and the assembled roll-over sheet added.

Stag Bodies builds the aluminium bodies to Elwell's own design and they're painted in his own workshop in Rugely.

"Aluminium bodies look terrific for a while in the metal but not so after a year or two," he says. With a good coat of paint he reasons, they look better longer, especially after a good washing down.

His tippers all have Hyva front-end tipping rams—Elwell shrewdly bought in a batch secondhand a few years back.

He employs a full time mechanic who, in between fixing the fleet, is kept busy repairing other operators' vehicles. He's also at one end of a tidy export operation selling secondhand trucks and components to New Zealand, where his father, Graham Elwell, now lives. In addition to all this he's established a small leasing fleet of 7.5-tonne tyre repair vehicles.

As he says: "At the end of the day we've got to keep looking for economies because there's never going to be any dramatic increase in the rates. And if all we did was operate tippers we'd be in a real sorry state—that's why we've diversified".

Elwell's trucks have had their fair share of transmission, tyre and differential troubles, but he points out: "If you could see the awful sites that my wagons have to tip on you wouldn't be at all surprised."

He's just ordered a new ERF EC11 tipper with 340hp Cummins Mll engine, and the spec will certainly include a Jake brake. fIe's also pleased to be returning to the latest Hendrickson rubber bogie suspension after having converted to ERF's steel suspension.

The steel-sprung bogie has been excellent but somehow Elwell's tippers ended up being 250kg heavier so there'll be extra payload with the new one.

The vertical exhaust and auto-lube come as standard; he reckons it's time the Jake also became part of the package "just like it does on the big 525hp models".

C by Bryan Jarvis