The cold craftsmen have it well under contro

Page 24

Page 25

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

IN THE offices of those who make major purchasing decisions in the road transport industry, company reputations generally count for almost as much as they do in the financial institutions off Threadneedle Street in the City of London.

Nowhere is this more evident than in the controlled-temperature sector of the industry. When a single 12.2m (40ft) refrigerated van, semi-trailer can cost little short of £25,000 and will be expected to have a life of no less than ten years, it is easy to understand why the purchasing company needs to be confident that the equipment's manufacturer will still be around in five years' time and be able to provide the service support it then needs.

The shrewd buyer will also want to be convinced of the quality of the construction and feel sure that the insulation properties of the body will not deteriorate drastically after a number of years in service.

At the same time, a manufacturer of controlled-temperature bodywork has to face the apparently conflicting requirement of keeping up with technical developments if he is not to risk falling behind his competitors. And nowadays there are many competitors.

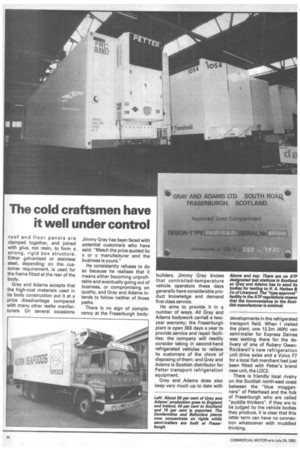

One builder that has continued to guard jealously its reputation for top quality workmanship while adopting, indeed to an extent pioneering, modern construction techniques is Gray & Adams Ltd of Fraserburgh, Scotland. Nowadays it is more strictly accurate to refer to the company as Gray and Adams Ltd of Fraserburgh, Dunfermline and Ballyclare, Northern Ireland. For there are manufacturing and service facilities at each of these locations. There is also an agent for the bodies in England in Atlas Refrigerated Vehicles Ltd of Nottingham.

The formation of the nE Northern Irish company, Gray Adams (Ireland) Ltd, on May this year marked the latest sta! in the Scottish bodybuildel modest expansion programn which has continued at a steal pace since 1974 when the cor pany switched to chassisle construction for its semi-trail vans.

The Dunfermline branch w, opened six and a half years ag and under the managership Bob Smith has proved successful venture. Now bodii up to 6.1m (20ft) long can t built at Ballyclare and Dunfern line, while the Frazerburgh he office and works concentratE on semi-trailers.

Justifiably, Jimmy Gray, wh co-founded the company 2 years ago and is now one of ii three directors, is proud th■ during an exceedingly bleg period for the semi-trailer ma ket over the past three year. when many jobs were lost at th larger manufacturers in the UP there were no redundancies Gray and Adams. 130 people ar employed at Fraserburgh, 25 E

unfermline and 25 at Ballyare.

Mr Gray is not a man to seek ublicity at every opportunity or boast of his company's chievements and he certainly oes not care much for the raz-natazz of marketing slogans nd high-powered advertising ampaigns, but when pressed e will tell you to what he attriutes the company's success: Refusing to compromise on uality, a good reputation, and heer hard work".

It is also clear that a major facPr in the success of Gray and ■ dams (co-founder Jim ■ dams is now technical director nd Lewis Gray is production irector) has been its ability to espond to, and in many cases, nticipate changing market denand.

The already-mentioned switch D chassisless semi-trailer contruction in the early seventies is good example, as is the hange to the type of one-piece aminate construction currently isod. That change was made in 978, in advance of many of its ompetitors in Britain.

Gray and Adams is unusual and perhaps unique now) among iritish reefer manufacturers vhich use composite panels in :ompleting the entire manufacuring process under one roof, hat is not buying in ready-made iandwich panels.

Jimmy Gray told me that his :ompany's first chassisless railers were built using bought n, ready made panels. His vason for preferring to build his pwn were that he had direct ::ontrol over the quality at every assembly stage and he had more flexibility in changing panel size or design if it were required.

The panelling now used is of Dutch, Heiwo design with an insulation core of Klegecell, expanded pvc foam, which comes from France. The major advantage of this type of insulation over the more usual polyurethane is that it is impermeable to water and so its weight and insulating properties should not be affected by water ingress during its life.

Gray and Adams claims a K factor (the coefficient of heat transfer) for a 12.2m (40ft) semitrailer with Klegocell insulation 80mm thick walls and 12Qmm thick roof panel, of 0.28 Kcal/hourisqm/deg C which is well below the minimum of 0.35 de mended for ATP heavily insulated Class "C" certification.

The Klegecell core on the Gray and Adams panel is sandwiched between two 9mm marine plywood panels. The inner side is faced with a one-piece polyester skin, cured at the Fraserburgh plant, and the outer face is an aluminium panel with a stove enamelled white finish, again one-piece construction.

This pre-finished aluminium alloy is easy to keep clean, durable and can provide the basis for an attractive livery, as was shown by the G and A-bodied vehicles operated by Christian Salvesen, BOC Transhield for Marks and Spencer, James McIntosh and Company Ltd of Aberdeen, Frigoscandia and numerous others, including major rental companies.

The elements of each panel are bonded together under compression but the details of the bonding process are, understandably, a close-kept secret. The complete front, side roof and floor panels are clamped together, and joined with glue, not resin, to form a strong, rigid box structure. Either galvanised or stainless steel, depending on the. customer requirement, is used for the frame fitted at the rear of the body.

Gray and Adams accepts that the high-cost materials used in its body construction put it at a price disadvantage compared with many other reefer manfacturers. On several occasions Jimmy Gray has been faced with potential customers who have said: "Match the price quoted by x or y manufacturer and the business is yours."

He consistently refuses to do so because he realises that it means either becoming unprofitable and eventually going out of business, or compromising on quality, and Gray and Adams intends to follow neither of those paths.

There is no sign of complacency at the Fraserburgh body

builders. Jimmy Gray knows that controlled-temperature vehicle operators these days generally have considerable product knowledge and demand first class service.

He aims to provide it in a number of ways. All Gray and Adams bodywork carrie§ a twoyear warranty; the Fraserburgh plant is open 363 days a year to provide service and repair facilities; the company will readily consider taking in second-hand refrigerated vehicles to relieve its customers of the chore of disposing of them; and Gray and Adams is Scottish distributor for Petter transport refrigeration equipment.

Gray and Adams does also keep very much up to date with developments in the refrigerated transport field. When I visited the plant, one 12.2m (40ft) van semi-trailer for Express Dairies was waiting there for the delivery of one of Rubery OwenRockwell's new refrigeration unit drive axles and a Volvo F7 for a local fish merchant had just been fitted with Petters brand new unit, the LOC2.

There is friendly local rivalry on the Scottish north-east coast between the "blue mogganners" of Peterhead and the folk of Fraserburgh who are called "puddle thinkers". If they are to be judged by the vehicle bodies they produce, it is clear that this latter term can have no connection whatsoever with muddled thinking.