New 7-ton 30 m.p.h. Cement Tanker Cuts Building Costs

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

IN cases where the scale of individual building operations has not been large, attempts to reduce costs by carrying cement in bulk have often been hampered by difficulties of storage on Site. The need for employing a tanker of the 20 m.p.h. category has been usually a further deterrent.

With the specific object of meeting the requirements of the small and medium-sized contract, a new System has been evolved jointly by F. Sh,epherd and Son, Ltd., building and engineering contractors, of York, the London Aluminium Co., Ltd., the Northern Aluminium Co., Ltd., and the Portasilo Co.. Blue Bridge Lane, York.

The working of the system was demonstrated at Ymk last week to a large gathering of public-works officials and contractors. The equipment consists of a 5-ton drop-sided lorry, Portasilo for handling bulk cement, a device known as the Pullwey Mechanical Cement Man, and a Big Bedford of the 30 m.p.h. class, constructed as a 7-ton cement tanker with containers and fittings produced by the London Aluminium Co., Ltd., in conjunction with the Northern Aluminium Co., Ltd.

These units have been evolved over the past two years in practical service with F. Shepherd and Son, Ltd. The objective has been to eliminate the cost of cement packages and to reduce the high unladen weight of the bulk-cement vehicles employed. By the use of aluminium alloy, the weight of the pressurized containers and ancillary equipment has been cut and the Big Bedford chassis has enabled a payload of over 7 tons to be achieved.

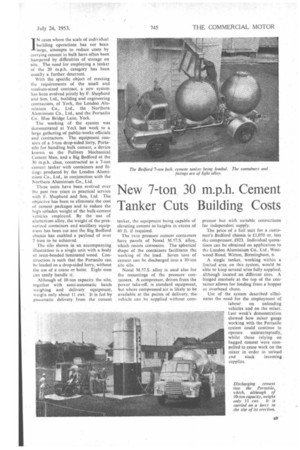

The silo shown in an accompanying illustration is a single unit with a body M resin-bonded laminated wood. Construction is such that the Portasilo can he loaded on a drop-sided lorry, without the use of a crane or hoist. Eight men can easily handle it.

Although of 10-ton capacity the silo, together with semi-automatic batch weighing and delivery equipment, meigits only about 11 cwt. It is fed by pneumatic delivery from the cement tanker, the equipment being capable of elevating cement to heights in excess of 40 ft. if required_

The twin pressure cement containers have panels of Noral M.57.S. alloy, which resists corrosion, The spherical shape of the containers facilitates the working of the load. Seven tons of cement can be discharged into a 10-ton site silo.

Noral M.57.S. alloy is used also for the mountings of the pressure containers. A compressor, driven from the power take-off, is standard equipment, but where compressed air is likely to be available at the points of delivery, the vehicle can be supplied without corn pressor but with suitable connections for independent supply_ The price of a full unit for a customer's Bedford chassis is £1,050 or, less tha compressor, £923. Individual quotations can be obtained on application to the London Aluminium Co., Ltd, Westwood Road, Witton, Birmingham, 6.

A single tanker, working within a limited area on this system, would be able to keep several silos fully supplied, although located on different sites. A hinged manhole at the top of the container allows for loading from a hopper or overhead chute.

Use of the system described Wailnates the need for the employment of labour on unloading vehicles and on the mixer. Last week's demonstration showed how mixer gangs working with the Portasilo system could continue to operate uninterruptedly, whilst those relying on bagged cement were compelled to cease work on the mixer in order to unload and stack incoming supplies.