FUEL SAVINGS ARE N TH

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

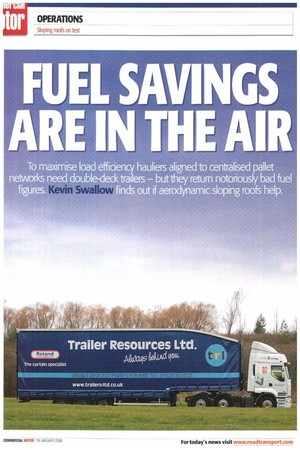

To maximise load efficiency hauliers aligned to centralised pallet networks need double-deck trailers — but they return notoriously bad fuel

figureirMirt.wa o finds out if aerodynamic sloping roofs help.

I he rise of centralised pallet 111 distribution and trunking has single handedly changed operators' fleets. Investment in double-deck trailers is vital, as they bring several advantages: by carrying two thirds more cargo, they save on manpower, fuel and running costs.

At night, on the motorway network, every other tractor driving to or away from the Midlands is pulling a double-deck — but most trailers have a flat front, giving them all the aerodynamic efficiency of a brick. Pitiful fuel returns are accepted by operators as a necessary evil. _ To overcome this trait manufacturers which specialise in doubledeck trailers have tried to create more fuelefficient designs in order to appease operators footing a raft of hefty fuel bills.The most common approach has been to introduce a more aerodynamic sloping roof, commonly called a 'cheese wedge'.

By slicing off the top of the headboard and sloping the roof from roughly the height • of the air-management kit, fuel efficiency is improved immediately.

That little piece of engineering reduces payload capacity and increases the price tag. But claims of 5-15% in subsequent fuel savings by • various trailer manufacturers are normally enough to warrant the purchasing decision. No manager would get fired for buying one— but what is the real fuel saving?

Commercial Motorwas keen to find out the true fuel saving a sloping front brings. So, with the help of Des O'Connor's Trailer Resources (Wake mine a doubler, CM17 January), proof was finally established.