BRAKING NEW GROUND

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

Volvo's Cumulo regenerative braking system can be used on city buses to great effect. It may sound a complicated idea but its appeal increases considerably when one realises it can cut fuel costs by a third

• Like most good ideas, regenerative braking is a simple concept. The principle of the system is to recover the braking energy generated when a bus pulls up, store it while the passengers get on or off and then release it to help the bus pull away.

The friction brakes fitted to a conventional city bus waste the vehicle's precious energy resources. In slightly more technical terms, the friction dissipates the bus's kinetic energy into heat which is then lost. The energy being wasted is fuel — and a major operator like London Buses spends some 218 million a year on diesel, so the potential for saving money is vast.

Buses working in cities are best placed to reap the rewards of regenerative braking, because they are constantly stopping and starting. The distance between stops can be tiny and traffic jams add to the stuttering pace at which most urban buses travel.

Regenerative braking is not new. Engineers have been toying with the idea for years and various designs have been formulated, using mechanical, electrical and hydraulic gadgetry. Volvo Flygmotor's Cumulo system uses hydraulic power and the giant Swedish company has been testing the design for some time now.

Not surprisingly, Volvo has tested its system in a city bus — the market which has the most to gain and will give its design the most punishing treatment.

REGENERATION

Hydraulic regeneration uses the bus's braking power to charge a high-pressure storage cylinder or accumulator with hydraulic fluid.

Once the braking effect has forced the fluid into the accumulator it is stored there as the passengers get on or off the bus: the pressurised fluid is then released to power a hydraulic motor which gets the vehicle underway.

In other designs electrical regenerators store the braking energy in batteries and use it to drive electrical motors, while mechanical systems usually store the ki netic energy by using it to spin a flywheel. The bus makes use of the flywheel's energy through a steppeddown clutch and gear system.

For any system to be a practical and commercial proposition, however, it will have to fit in with a wide range of different diesel engines and drive trains. Hydraulic systems could have the edge here because they don't need batteries or flywheels.

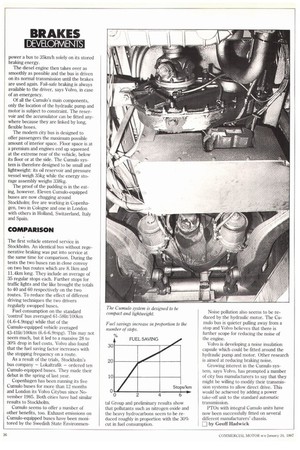

Volvo's Cumulo system connects a variable-displacement hydraulic pump and motor to the bus's automatic transmission: a microprocessor controls everything using data picked up by sensors on the brakes and the accelerator pedal in the driver's cab. The hydraulic oil is stored in a separate tank.

Immediately the bus brakes, the Cumulo system takes over. The bus engine is automatically switched to idle and the transmission knocked into neutral. The braking energy is then diverted into the hydraulics and fluid is pumped into the accumulator, which uses a plunger within the cylinder which in turn acts against a pocket of gas.

The accumulator is capable of storing braking energy ranging from a half-loaded bus travelling at 50Iun/h on a flat road, to a brake dab in urban traffic. When the bus accelerates, the pressurised fluid is released from the accumulator to drive the hydraulic motor which drives directly to the bus's wheels. When the Cumulo accumulator is fully charged it is also to power a bus to 35Ianfh solely on its stored braking energy.

The diesel engine then takes over as smoothly as possible and the bus is driven on its normal transmission until the brakes are used again. Fail-safe braking is always available to the driver, says Volvo, in case of an emergency.

Of all the Cumulo's main components, only the location of the hydraulic pump and motor is subject to constraint. The reservoir and the accumulator can be fitted anywhere because they are linked by long, flexible hoses.

The modern city bus is designed to offer passengers the maximum possible amount of interior space. Floor space is at a premium and engines end up squeezed at the extreme rear of the vehicle, below its floor or at the side. The Cumulo system is therefore designed to be small and lightweight: its oil reservoir and pressure vessel weigh 35kg while the energy storage assembly weighs 338kg.

The proof of the pudding is in the eating, however. Eleven Cumulo-equipped buses are now chugging around Stockholm; five are working in Copenhagen, two in Cologne and one in London with others in Holland, Switzerland, Italy and Spain.

COMPARISON

The first vehicle entered service in Stockholm. An identical bus without regenerative braking was put into service at the same time for comparison. During the tests the two buses ran in close convoy on two bus routes which are 8.1km and 11.41cm long. They include an average of 35 regular stops each. Further stops for traffic lights and the like brought the totals to 40 and 60 respectively on the two routes. To reduce the effect of different driving techniques the two drivers regularly swopped buses.

Fuel consumption on the standard 'control' bus averaged 61-581it/1001cm (4.6-4.9mpg) while that of the Cumulo-equipped vehicle averaged 43-41kt/100km (6.6-6.9mpg). This may not seem much, but it led to a massive 28 to 30% drop in fuel costs. Volvo also found that the fuel saving factor increases with the stopping frequency on a route.

As a result of the trials, Stockholm's bus company — Lokaltrafik — ordered ten Cumulo-equipped buses. They made their debut in the spring of last year.

Copenhagen has been running its five Cumulo buses for more than 12 months and London its Volvo Citybus since November 1985. Both cities have had similar results to Stockholm.

Cumulo seems to offer a number of other benefits, too. Exhaust emissions on Cumulo-equipped buses have been monitored by the Swedish State Environmen tal Group and preliminary results show that pollutants such as nitrogen oxide and the heavy hydrocarbons seem to be reduced roughly in proportion with the 30% cut in fuel consumption. Noise pollution also seems to be reduced by the hydraulic motor. The Cumulo bus is quieter pulling away from a stop and Volvo believes that there is further scope for reducing the noise of the engine.

Volvo is developing a noise insulation capsule which could be fitted around the hydraulic pump and motor. Other research is aimed at reducing braking noise.

Growing interest in the Cumulo system, says Volvo, has prompted a number of city bus manufacturers to say that they might be wilting to modify their transmission systems to allow direct drive. This would be achieved by adding a power take-off unit to the standard automatic transmission.

PTOs with integral Cumulo units have now been successfully fitted on several different manufacturers' chassis.

by Geoff Hadwick