TYRING ORK

Page 104

If you've noticed an error in this article please click here to report it so we can fix it.

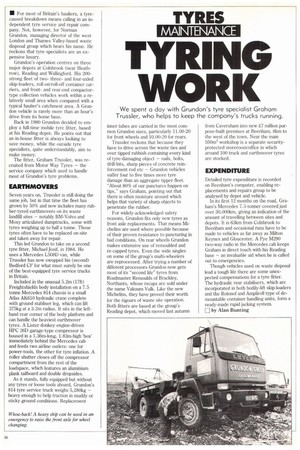

We spent a day with Grundon's tyre specialist Graham Trussler, who helps to keep the company's trucks running.

• For most of Britain's hauliers, a tyrecaused breakdown means calling in an independent tyre service and repair company. Not, however, for Norman Grundon, managing director of the west London and Thames Valley-based waste disposal group which hears his name. He reckons that tyre specialists are an expensive luxury.

Grundon's operation centres on three major depots at Colnbrook (near Heathrow), Reading and Wallingford. His 200strong fleet of twothreeand four-axled skip-loaders, roll-on/rolt-off container carriers, and frontand rear-end compactortype collection vehicles work within a relatively small area when compared with a typical haulier's catchment area, A Grundon vehicle is rarely more than an hour's drive from its home base.

Back in 1980 Grundon decided to employ a full-time mobile tyre fitter, based at his Reading depot. He points out that an in-house fitter is always looking to save money, while the outside tyre specialists, quite understandably, aim to make money.

The fitter, Graham Trussler, was recruited from Motor Way Tyres — the service company which used to handle most of Grundon's tyre problems.

EARTHMO'VERS

Seven years on, Trussler is still doing the same job, but in that time the fleet has grown by 50% and now includes many rubber-tyred earthmovers on its waste landfill sites — notably BM-Volvo and Moxy articulated dumptrucks, some with tyres weighing up to half a tonne. Those tyres often have to be replaced on-site and taken away for repair.

This led Grundon to take on a second tyre fitter, Michael Josif, in 1984. He uses a Mercedes L508D van, while Trussler has now swopped his (second) Bedford CF for what must surely be one of the best-equipped tyre service trucks in Britain.

Included in the unusual 5.2m (17ft) Freightshields body installation on a 7.5 tonne Mercedes 814 chassis is a small Atlas AK610 hydraulic crane complete with ground stabliser leg, which can lift 375kg at a 3.2m radius. It sits in the lefthand rear corner of the body platform and can handle the heaviest earthmover tyres. A Lister donkey engine-driven HPC 26D garage-type compressor is housed in a 1.36m-long, 1.83m-high 'box' immediately behind the Mercedes cab and feeds two airline outlets one for power-tools, the other for tyre inflation. A roller shutter closes off the compressor compartment from the rest of the loadspace, which features an aluminium plank tailboard and double dropsides.

As it stands, fully equipped but without any tyres or loose tools aboard, Grundon's 814 tyre service truck weighs 5,280kg — heavy enough to help traction in muddy or sticky ground conditions. Replacement inner tubes are carried in the most common Grundon sizes, particularly 11.00-20 for front wheels and 10.00-20 for rears.

Trussler reckons that because they have to drive across the waste ties and over tipped rubbish containing every kind of tyre-damaging object — nails, bolts, drill-bits, sharp pieces of concrete reinforcement rod etc — Grundon vehicles suffer four to five times more tyre damage than an aggregate tipper fleet. "About 80% of our punctures happen on tips," says Graham, pointing out that there is often moisture around which helps that variety of sharp objects to penetrate the rubber.

For widely-acknowledged safety reasons, Grundon fits only new tyres as front axle replacements. That means Michelins are used where possible because of their proven resistance to puncturing in bad conditions. On rear wheels Grundon makes extensive use of remoulded and re-capped tyres. Even the wide singles on some of the group's multi-wheelers are reprocessed. After trying a number of different processors Grundon now gets most of its "second life" tyres from Roadmaster Remoulds of Brackley, Northants, whose recaps are sold under the name Vakuum Vulk. Like the new Michelins, they have proved their worth for the rigours of waste site operation. Both fitters are based at the group's Reading depot, which moved last autumn from Caversham into new .27 million purpose-built premises at Beenham, 8km to the west of the town. Near the main 550m3 workshop is a separate securityprotected storeroom/office in which around 100 truck and earthmover tyres are stocked.

EXPENDITURE

Detailed tyre expenditure is recorded on Beenham's computer, enabling replacements and repairs group to be analysed by depot and vehicle.

In its first 12 months on the road, Graham's Mercedes 7.5-tonner covered just over 30,000km, giving an indication of the amount of travelling between sites and depots. It is 63km from Colnbrook to Beenham and occasional runs have to be made to vehicles as far away as Milton Keynes and Gloucester. A Pye M290 two-way radio in the Mercedes cab keeps Graham in direct touch with his Reading base — an invaluable aid when he is called out to emergencies.

Though vehicles used on waste disposal lead a tough life there are some unexpected compensations for a tyre fitter. The hydraulic rear stabilisers, which are incorporated in both bodily-lift skip-loaders and the Rolonof and Ampliroll type of demountable container handling units, form a ready-made rapid jacking system. Li by Alan Bunting