SPEEDING TH TURN-ROUND IAULAGE IN BEET

Page 38

Page 39

Page 40

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

Outstanding improvement in the Arra at Bardney, Lincs. Hauliers Can

tents for the Reception of Road Vehicles ce Fullest Advantage of it Only by rig Lorries Using 7 SUGAR is a topical subject. A few minutes before writing this article I was reading in the daily papers that important negotiations are in progress concerning the proportion of 'Cuban sugar that is likely to come to this country. There is, it seems, a prospect of that proportion being very small indeed, and I gather that the discussions have as their object some slight increase in the quantity which we shall receive. Only a day or two before this Mr. Strachey had announced that there was some prospect of a small increase in the sugar supplies during the year.

The crop of sugar beet in this country, according to latest information, will approximate to 4,300,000 tons, which is slightly better than that of last year, although the acreage under sugar beet is the same. The yield is rather better than average and is likely to be, in round figures, 11 tons per acre. Moreover, the sugar content is only slightly below normal. This is rather unexpected, for it had been prophesied that, because of the wet weather, the sugar content was likely to be low.

The tonnage of sugar beet that farmers will take to the factory will be greater, and they will receive more for it, being paid on the basis of a yield of 151 per cent. sugar to beet. The proportion is more likely to be in the neighbourhood of 16 per cent., and as the farmers are paid 4d. per ton extra for each 0.1 per cent. above 15/ per cent., they will receive an average of an extra Is. 8d. per ton from the crop this year.

The net yield of refined sugar is not the full 151-16 per cent., but is nearer to 13 per cent. Of that 151 or 16 per cent., a certain quantity issues as molasses; in.addition, there are certain impurities. The net yield of refined sugar is estimated at over --500,000 tons.

Hall, the improved sugar content, but because of the Hauliers will benefit, too, not as the result of increased yield per acre, which means that there T. E. One of the most interesting things about sugar beet is the way in which the traffic has passed from rail to road. In the beginning it was expected that 75 per cent. to 80 per cent. of the sugar crop would be brought to the factories by rail and the balance by road. To-day those figures are reversed. 75-80 per cent, of the crop being brought by road and the rest by rail. One of the most interesting points in my own study of sugatbeet haulage, which has gone on now for nearly 20 years, is the way in which the various beet-sugar factories have gradually, year by year, found it advisable to improve the conditions under which the beet is unloaded from road vehicles.

It was such an improvement, which I was informed had been carried out during the summer at Bardney, Lincs, that led me to pay a visit to that factory. There I was received by Mr. C. E. M. Scott, the manager, who gave me not only much of the information which is embodied in this article, but all the facilities to take the photographs with which it is illustrated.

This factory has a capacity to slice 2,400 tons of beet per day. Usually the "campaign," as it is called, starts towards the close of September and finishes at the end of December or the first week of January. The high acreage and exceptional yield have had the effect of lengthening the past two campaigns, and this season is likely to end after the middle of February.

Last year, in order to make conditions even among the various factories, a dead-line of February 10 was fixed, and factories which had a surplus dispatched it to others not so well placed All the factories were thus able to finish on time. In .this connection, it is interesting to note that at BardneY a total of '288,000 tons was sliced, but of that total 53,000 tons came from Norfolk.

Arising from this, I raised the question of cost of transport when beet is taken away from the factory to which it is normally consigned, and conveyed some distance to facilitate organization within the factories. I was told that the excess cost of carriage over and above that normally chargeable in conveying the beet to the usual factory is paid by the British Sugar Corporation, Ltd. .

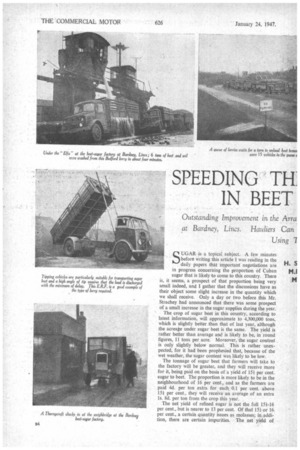

To facilitate deliveries of beet by road, an engineering feat of some magnitude has been carried out at Bardney. This is the building of an overhead roadway, similar in general principles to that which 'I described a couple of years ago as having been erected at the Brigg factory. but differing somewhat in detail.

Some technical particulars may be of interest. The structure is of reinforced concrete, with 15-in. by 6-in, beams in the roadway, carried on reinforced concrete columns and solid concrete walls. The top of the roadway is 13 ft. high from the road level. It is 300 ft. long and 36 ft. wide between 1-ft. thick kerbs

The roadway is supported every 10 ft. by 15-in, square reinforced-concrete columns. Between these is a continuous solid concrete wall 15 ins. thick. The roadway is designed to.carry a load of 3 cwt, per ft. superficial.

The approach is 177 ft. long by 10 ft. wide, having a gradient of 1 in 12. The top part is carried on 15-in. Square' concrete columns, with reinforced concrete 9i ins. thick for the roadway. The down ramp is 90 ft. long by 10 ft. wide, with a gradient of 1 in 8, and the roadway is similar in construction to that of the approach.

An important feature of the roadway is that it overhangs 6 ft. on each side of the supporting walls. The object is to facilitate the delivery of beet by tipping it off the edge of the roadway into the silo below.

VOW Months' Work The structural materials were reinforced by the British Reinforced Concrete. Co., and detailed plans were supplied by that company. The work was commenced in May and completed at the beginning of September. It was carried out by 24 of the Corporation's own men.

A point of interest arises here, as showing the value of a little financial encouragement when it is desired that work be completed in the minimum of time. At the beginning these men were laying 38 cubic yds. of concrete per week. A bonus was then offered for anything over 40 cubic yds., and, as a result, the figure rose up to 70 cubic yds. Moreover, the employees were so interested ' in the job and in getting it done that they completed it without the need for much overtime.

The object of building this roadway is to accelerate the turn-round of lorries. It is designed specifically for use by tipping vehicles, which can back up to the substantial kerb which runs along the edge of the road. tip the whole of the load into the silo below, and drive straight away again. Full advantage cannot, therefore, be taken of this improvement in the facilities available unless there be a large proportion of tipping vehicles employed.

Hauliers cannot but appreciate the benefits conferred by this innovation. Previously the sugar beet, or a good deal of it, was .unloaded by hand into silos or flumes by the side of the road. As the flumes filled, the level of the beet rose to a height in excess of that of the vehicles, so that for a large proportion of the time drivers and their mates had actually to throw the's4,ar beet upwards by hand on to the heaps in the silos.

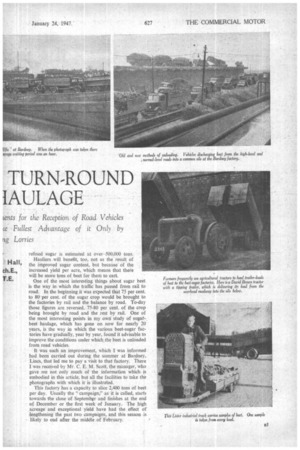

The situation now is that there are three methods whereby sugar beet can be unloaded at this factory. The vehicles can run under the " Elfa," whence the beet is washed off by powerful jets of water, being

delivered thence into flumes which carry it straight into the factory, where it is immediately processed. Alternatively, the beet can be unloaded by hand into the silos.

Tipping Into Silos .

Up to this year, only those two, methods were available Construction of the new overhead roadway has made the third method practicable—that Of tipping the beet direct into the existing says or flumes.

At present, .46 per cent. of the load is washed off the lorries, 34 per cent. is unloaded by hand and the balance of 20 per cent. tipped.

So far as the driver is concerned, and in the absence of tipping vehicles, unloading by means of the "'pa " is most attractive. It is quick and involves no labour whatever on his part. Unfortunately, this method involves waiting in a queue for a turn beneath the "El fa." The waiting time, naturally, varies with the. number of vehicles arriving. The time needed for the " Elfa " to unload a 6-ton lorry is 4 mins., but if, as was the case at the time of my visit, there be 15 lorries in the queue, an hour is spent in waiting. The total time expended is thus an hour's wait, 4 mins, for unloading, plus a few minutes while being weighed in and out.

For hand unloading there is practically no waiting, but it takes an hour or so to unload, so that the time occupied is practically the same as with the " Elfa."

With tippers there i practically no queuing. The load is unshipped in a matter of minutes, and an average time for a tipping vehicle to be in the yard is 15-20 cams.

Hauliers must obviously concentrate on acquiring as many tipping vehicles as they can in time for the next sugar-beet season. By so doing they will be able to increase the number of loads that they can deliver to the factory by at least one per day. No haulier, even with the most elementary knowledge of costing, will fail to appreciate what that means in respect of the profit that he can earn in a full season in transporting sugar beet.

Rates Increased On the question of rates which hauliers are receiving, Mr. Scott tells me that, so far as he is aware, practically every operator is working to a schedule of rates issued by the Road Haulage Association. A table of these rates is included with thia article, together with those for 1945 There has been a slight increase, justified, in my opinion, by rises in -costs. In no case does the increase exceed Is Id. per ton, which relates to mileages from 24 to 27. For mileages up to five the rise in price is only 6d. per ton.

On the matter ot rates, Mr. Scott, without criticizing this schedule, suggests that hauliers should be careful not to make any attempt to raise the rates they charge beyond the economic level, because that will increase the tendency for farmers to use their own lorries or tractors. At the present time, approximately 30 per cent. of beet Nought tO this factory is carried on farmers' vehicles Even if he has no lorry, nearly every farmer has a tractor and can bring the beet in on a suitable trailer

Tractors for Haulage ' I suggested to Mr. Scott that farmers ought surely to be able to find work for the tractor on the land, which would be more profitable to them than carting sugar beet, but he tells me that it is now possible, with the use of mechanization, to get ploughing over so quickly that there is no difficulty in releasing the tractor for haulage

On this point it is of interest to quote the comment of a haulage contractor who was actually engaged on hauling beet to Bardney. He confirmed that many farmers are buying lorries and using them to carry beet. Those who are doing so are under a complete misapprehension as to the cost and are apt to debit no more than petrol, oil and drivers' wages against the vehicle, making no provision for depreciation, maintenance and tyres. Indeed, they are now in the state of mind which was common to so many haulage contractors 10 or 15 years ago, when they were new to business.

This haulier, Mr. Bradshaw, is in a favourable position as regards sugar-beet haulage, as his headquartei s ,are centrally located between the three factories at Brim, Bardney and Kelham. He is approximately 20 miles from each and is therefore able to execute contracts of haulage to all of them.

He, nevertheless, admits that the threat to the haulier implied in the farmer's use of his own vehicles, is a serious one. In his view, however, most farmers fight shy of hauling over distances in excess of 10 miles Those who do haul beyond that radius and are using tippers can average as many as five loads daily, and have actually brought in seven loads per day.

Disciplining Hauliers The permit system, so often described in "The Commercial Motor," is, of course, in use at Bardney. and Mr Scott tells me that hauliers work fairly well to it. Any haulier attempting to "jump it" is put on the mat and, as a rule, behaves himself subsequently It is pointed out that the permit system is installed in the haulier's own interest, so as to minimize congestion and queuing.

During my day at the factory I could not avoid being impressed by the fact that there are so few large vehicles employed. I estimated that 90-95 per cent. were of 5-ton nominal capacity. Mr. Scott confirms this impression. He tells me that the average net load per vehicle is 51 tons of beet, which is equivalent to appro.cimately a 6-ton load of beet and dirt.

The few larger vehicles are usually from distances of approximately 30 miles, from farms near Boston, Skegness and Mablethorpe. It is for tilt:6e leads that large vehicles, and lorries with trailers, are usually employed. It is interesting to note that the average intake at this factory during the season is 400 lorries per day, occasionally rising to as many as 500.

Maintaining Constant -Flow A problem which is constantly in the mind of the manager of a beet-sugar factory is that of maintaining a constant flow of beet to the slicing machines. Broadly speaking, this object is achieved at Bardney as follows:—

The sugar beet, which is unloaded from the road vehicles during the day by the "Ella," is, as has already been stated, carried direct into the factory and provides sufficient material to keep the machines busy' during the period when road vehicles are being unloaded in that way. At night, railway wagons are brought beneath the " Elfa " At the week-ends and in emergencies, when the Elfa " is not operating, the sugar beet which is piled into the silos serves to keep the wheels turning. It is carried through in streams of water, which flow in sluices in the centre of the floor of the silos.

Storage in Water Abandoned

Until recently, a further method of ensuring this steady flow of beet was in use at Bardney. It was similar to that described in a previous article as applying in the case of the factory at Brigg. Any excess of beet from the " Elfas " was pumped to elevated sluices, where it was stored until required. That method of dealing with sugar beet has been discontinued at Bardney, because it was found that there was a loss of sugar content when the beet was stored temporarily in water: It is almost impossible, having in mind the figures quoted in the early paragraphs of this article, to avoid the reflection that the manufacture of beet sugar is an industry which could never have reached its present proportions, or been so succeskful, in the absence of an efficient service of road transport. By dint of private enterprise, road vehicles provide annually for the conveyance of over 3,000,000 tons of sugar beet over distances averaging 12 miles, equivalent to 500,000 wagonloads in 100 working days.