A NEW TWO-PART PISTON.

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

A Resume of Recently Published Patent Specifications.

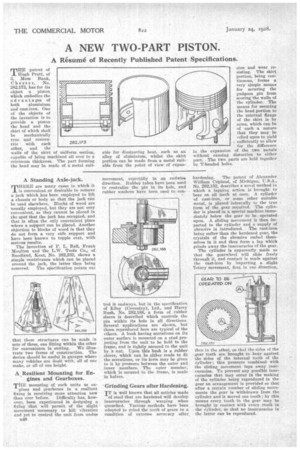

THE patent of Hugh Pratt, of 3, Moss Bank,

Chester, No. 282,173, has for its object a piston which embodies the advantages of both aluminium and cast-iron. One of the objects of the invention is to provide a piston the head and the skirt of which shall be mechanically true and concentric with each other, and the walls of the Skirt of uniform section, capable of being machined all over to a minimum thickness. The part forming the head may be made of a metal suit

A Standing Axle-Jack.

THERE are many eases in which it is convenient or desirable to remove a jack which has been employed to lift a chassis or body so that the jack can be used elsewhere. Blocks of wood are usually employed, but they are not very convenient, as they cannot be placed in the spot that the jack has occupied, and that is often the only convenient place where a support can be placed. Another objection to blocks of wood is that they do not form a very safe support and have been known to topple over, with serious results.

The invention of F. L. Ball, Prank Moulton and the L.W. Tools Co., of Snodland, Kent, No. 282,232, shows a simple-contrivance which can be placed around the jack, the latter then being

removed. The specification points out that these structures can be made in sets g three, one fitting within the other for convenience in stating. We illustrate two forms of construction. The device should be useful in garages where many vehicles are dealt with, all of one make, or all of one height.

A Resilient Mounting for Engines and Gearboxes.

THE mounting of, such units as en gines and gearboxes in a resilient fixing is receiving more attention now than ever before. Difficulty has, however, been experienced in designing a Mang that will permit of the slight Movement necessary to kill vibration and yet to control the unit from undue B48 able for dissipating heat, such as an alloy of aluminium, whilst the skirt portion can be made from a metal suitable from the point of view, of expan movement, especially in an endwise direction. Rubber tubes have been used to centralize the pin in its hole, and rubber washers have been used to con trol it endwoys, hut in the specification of Riley (Coventry), Ltd., and Harry Rush, No. 282,188, a form of rubber sleeve is described which controls the pin within its hole in all directions. Several applications are shown, but those reproduced here are typical of the others. A bush having serrations on its outer surface is mounted on a stud projecting from the unit to be held to the frame, and is tightly secured to the unit by a nut. Upon this bush is a rubber sleeve, which can be either made to fit the serrations, or its form may be given to it by pressure between the outer and inner members. The outer member, which is secured to the frame, is made in halves.

Grinding Gears after Hardening.

IT is well known that all articles made of steel that are hardened will develop inaccuracies through warping when quenched. Various methods have been adopted to grind the teeth of gears to a condition of extreme accuracy after,

sion and wear resisting. The skirt portion, being continuous, forms a very simple means for securing the gudgeon pin from scoring the walls of the cylinder. The means for securing the head portion to the internal flange of the skirt is by arms, which can be of such a nature that they may be relied upon to yield sufficiently to allow for the difference in the expansion of the two' Metals without causing distortion to either part. The two parts are held together by T-headed bolts.

hardening. The patent of Alexander William Copland, of Michigan, 'U.S.A., No. 282,152, describes a novel method iii which a lapping action is brought to bear on all teeth at .once. A cylinder of cast-iron, or some other suitable metal, is planed internally to the true form of the gear required. The cylinder is placed in a special machine immediately below the gear to be operated upon. A sliding movement is then imparted to the cylinder and a supply of abrasive is introduced. The cast-iron being softer than the hardened gear, the crystals of the abrasive embed themselves in it and thus form a lap which grinds away the inaccuracies ef the gear.

The cylinder is apparently made so that the gearwheel will slide freely through it, and contact is made against the cast-iron by imparting a slight Totary movement, first in one direction,

then in the other, so that the sides of the gear teeth are brought to hear against the sides of the internal teeth of the cylinder ; this pressure combined with the sliding movement laps away inaccuracies. To prevent any possible inaccuracies that may occur in the making of the cylinder being reproduced in the gear an arrangement is provided so that after a certain number of sliding movements the gear is withdrawn from the cylinder and is moved one tooth ; by this means every tooth in the gear may be brought in contact with every tooth -in the cylinder, so that no inaccuracies in the latter can be reproduced.