THE AFTER-THE-WAR HALLEY

Page 8

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

Radical Departure from Existing Designs.

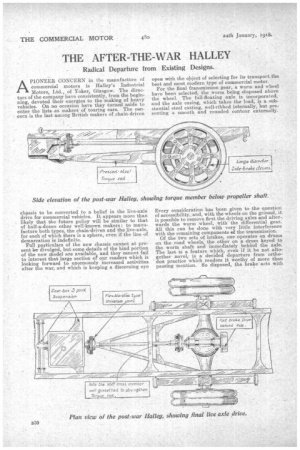

APIONEER CONCERN in the manufacture of commercial motors is Halley's Industrial Motors, Ltd., of Yoker, Glasgow. The directors of the company have consistently, from the beginning, devoted their energies to the making of heavy vehicles. On no occasion have they turned aside to enter the lists as makers of touring ears. The eiancern is the last among British makers of chain-driven

chassis to be converted to a belief in the live-axle drive for commercial vehicles. It appears more than likely that the future policy will be similar to that of half-a-dozen other well-known makers : to manufacture both types, the chain-driven and the live-axle, for each of which there is a sphere, even if the line of demarcation is indefinite.

Full particulars of the new chassis cannot at present be divulged, but some details of the hind portion of the new model are available, and they cannot fail to interest that large section of our readers which is looking forward to enormously increased activities after the war, and which is keeping a discerning eye open with the object of selecting for its transport the hest and most modern type of commercial motor.

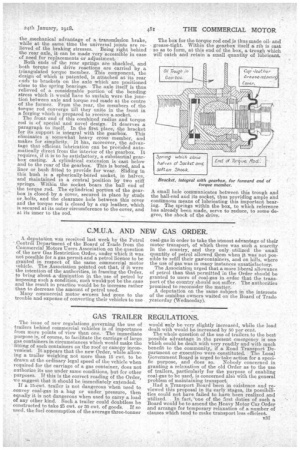

For the final transmission gear, a worm and wheel have been selected, the wornt being disposed above the wheel. The full-floating axle is incorporated, and the axle casing, which takes the load, is a substantial steel casting, well-ribbed internally, but presenting a smooth and rounded contour externally.

Every consideration has been given to the question of accessibility, and, with the wheels on the ground, it is possible to remove first the -driving axles and afterwards the worm wheel, iviththe differential gear. All this can be done with very little interference with the remaining components of the transmission.

Of the two sets of brakes, one operates on drums on the road wheels, the other on a drum keyed to the worm shaft and immediately behind the axle. The last is a feature which, even if it be not altogether novel, is a decided departure from orthodox practice which renders it worthy, of more than passing mention. So disposed, the brake acts with the .mechanical advantage of a transmission brake, while at the same time the universal joints are relieved of the braking stresses. Being right behind the rear axle, it can be made very accessible in case of need for replacements or adjustment. Both ends of the rear springs are shackled, and both torque and drive reactions are carried by a triangulated torque member. This component, the design of which is patented, is attached at its rear ends to brackets on the axle which are positioned close to the spring bearings. The axle itself is thus relieved of a considerable portion of the bending stress which it would have to sustain were the junction between axle and torque rod made at the centre of the former. From the rear, the members of the torque rod converge till they unite in the front in a forging which is prepared to receive a. socket. The front end of this combined radius and torque rod is of special and novel design. It deserves a paragraph to itself. In the first place, the bracket for its support is integral with the gearbox. This eliminates a somewhat heavy cross member, and makes for simplicity. It has, moreover, the advantage that efficient lubrication can be provided automatically direct from the interior of the gearbox. It requires, if it is to be satisfactory, a substantial gearbox casting. A cylindrical extension is cast below and to the rear of the gearbox. This is bored, and a liner or bush fitted to provide for wear. Sliding in this bush is a spherically-bored socket, in halves, and maintained in a central position by two stiff springs.. Within the socket bears .the ball end of the torque rod. The cylindrical portion of the gearbox is closed by a cover, secured in place by studs or, bolts, and the clearance hole between this cover and the torque rod is closed by a cup leather, which is secured at its outer circumference to the cover, and at its inner to the rod. The box for the torque rod end is thus made oiland grease-tight. Within the gearbox itself a, rib is cast so as to form, at this end of the box i a trough which will catch and retain a small quantity of lubricant.

A small hole communicates between this trough and the ball-end and its socket, thus providing ample and continuous means of lubricating this important bearing. The springs within the box, to which reference has already been made, serve to reduce, to some degree, the shock of the drive.