For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

If A PRIZE OF TEN. SHILLINGS is awarded each week to the sender of the best letter which we publish on this p „e ; all others are paid for at the rate of a penny a line, with an allowance for photographs. All notes are edited befor lig published. Mention pour employer's name, in confidence. as evidence of good faith, Address, D., M. and F„ JR Commercial Motor," 7-1.5, .Rosebery Avenue, London, E.G. 1.

Lamps Alight—

Light your lamps at 5.11 in 'London, 5,36 in Edinburgh, 5.4 in Newcastle, 5,15 in Liverpool, 5.14 in Birmingham, 5.21 in Bristol, and 5.38 in Dublin.

A Useful Garage Trolley.

The sender of the following communication has been awarded the 108 prize this week.

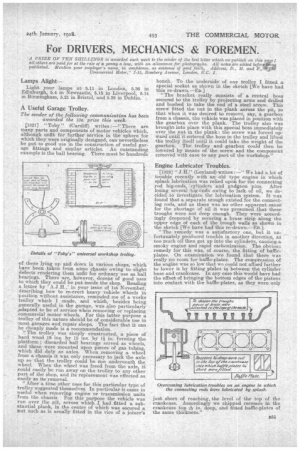

118211 " Toby " (Cardiff) writes :—" There are many parts and components of motor vehicles which, although unfit for further service in the sphere for which they were originally designed, can nevertheless be put to good use in the construction of useful garage fittings and siniilar articles. An outstanding example is the ball bearing. There must be hundreds of these lying up and down in various shops, which have been taken from same chassis owing to slight defects rendering them unfit for ordinary use as ball bearings: There are, hewever, dozens of good uses to which they could be put inside the shop. Reading a letter by A.J.H.,' in your issue of 1st November, describing how to re-erect heavy vehicle .wheels in position without assistance, reminded me of a works trolley which I made, and which, besides being generally useful in the garage, was also particularly adapted to be of service when removing or replacing commercial motor wheels. For this latter purpose a trolley of this nature should be. of considerable use in most garages and repair shops. The fact that it can be cheaply made is a recommendation.

"The trolley was simply constructed, a piece of hard wood 18 ins. by 15 ins, by l in. forming the .platform ; discarded ball bearings served as wheels, and these were mounted upon pieces of gas tubing, which did duty as axles. When .removing a, wheel from a chassis it was only .necessary to jack the axle up so that the trolley could be run underneath the .wheel. When the wheel was freed from the axle, if could easily be run away on the trolley to any other part of the shop, and its replacement was effected as easily as its removal.

"After a, time other uses for this particular type of trolley suggested themselves. In particular it came in useful when removing engine or transmission units from the chassis. For this purpose the vehicle was 'run over the pit, across. which, I. had fitted a substantial plank, in the centre of which was secured a nut such as is usually fitted in the vice of a joiner's bench. To the underside of one trolley I fitted a special socket as shown in the sketch LWe have had this re-drawn.—En.]

"The bracket really consists of a central boss secured to the trolley by projecting arms and drilled and bushed to take the end of a steel screw. This screw fitted the nut in the plank across the pit, so that when it was desired to remove, say, a gearbox from a chassis, the vehicle was placed in position with the gearbox over the plank. The trolley also was brought into place with this special boss immediately over the nut in the plank : the screw was forced upWard until it' entered the boss in the trolley and lifted the trolley itself until it could take the weight of the gearbox. The trolley and gearbox could then be lowered by 'means of the screw and the component removed with ease to any part of the workshop.

Engine Lubricator Troubles.

" J.H." (Leyland) writes :—" We had a. lot of trouble recently with an old type engine in which splash lubrication was relied upon for the connecting rod big-ends, " cylinders and gudgeon pins. After losing several .big-encls -owing to lack of oil, we decided to investigate the lubrication system. It was found that a separate trough existed for the connecting rods, and as there. was no other apparent. cause for the shortage of oil it was presumed that these troughs were not deep enough. They were accordingly deepened. by securing a brass strip along the upper edge of each of the trough walls as shown in the sketch [We have had this re-drawn.—En.].

"The remedy was a satisfactory_ one, but it unfortunately produced trouble in another direction, as too much oil then got up into the cylinders, .cauSing,a smoky engine and rapid carbonization. The obvious, remedy for this was, of course, the fitting of baffle

plates. On examination we found that there was really no room-for baffle-plates. The compression of the engine was so low that we could not afford further to lower it by fitting pIales in between the cylinder base and crankcase. In any case this would have had the effect of bringing the bottom edges of the pistons into contact with the baffle-plates, as they were only