1 t was at the back end of 1995 that

Page 28

Page 30

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

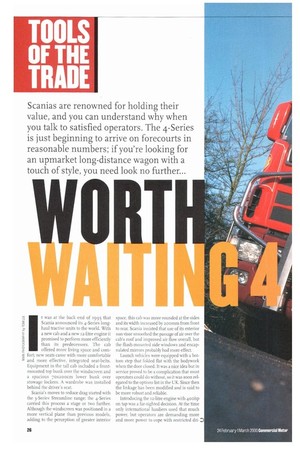

Scania announced its 4-Series long. haul tractive units to the world. With a new cab and a new 12-litre engine it promised to perform more efficiently than its predecessors. The cab offered more living space and com

1 t was at the back end of 1995 that

Scania announced its 4-Series long. haul tractive units to the world. With a new cab and a new 12-litre engine it promised to perform more efficiently than its predecessors. The cab offered more living space and com fort; new seats came with more comfortable and more effective, integrated seat-belts, Equipment in the tall cab included a front. mounted top bunk over the windscreen and a spacious 7ox2o0cm lower bunk over stowage lockers. A wardrobe was installed behind the driver's seat.

Scania's moves to reduce drag started with the 3-Series Streamline range; the 4-Series carried this process a stage or two further. Although the windscreen was positioned in a more vertical plane than previous models, adding to the perception of greater interior space, this cab was more rounded at the sides and its width increased by zoornm from front to rear. Scania insisted that use of its exterior sun visor smoothed the passage of air over the cab's roof and improved air flow overall, but the flush-mounted side windows and encapsulated mirrors probably had more effect.

Launch vehicles were equipped with a bottom step that folded flat with the bodywork when the door closed. It was a nice idea but in service proved to be a complication that most operators could do without, so it was soon relegated to the options list in the UK. Since then the linkage has been modified and is said to be more robust and reliable.

Introducing the 12-litre engine with 400hp on tap was a far-sighted decision. At the time only international hauliers used that much power, but operators are demanding more and more power to cope with restricted dri ving hours, lower speed limits, heavier weights and increased fuel costs. The x ohpplus-per-tonne benchmark still holds good for 41 tonnes on domestic work.

The 36ohp mechanical-injection and 400hp EDC six-cylinder charge-cooled engines incorporated four valves per cylinder in separate cylinder heads with injectors positioned vertically in the centre of each cylinder.

Designed with a hot and cold side, the engine layout separated the fuel system from the exhaust.

Timing gears were installed at the rear of the engine with the flywheel, while an in

line flangemounted pump

was driven directly from the timing mechanism, just like the servo pump for the power steer ing. E DC (Electronic Diesel Control) ensured that fuel was injected in precise quantities to burn efficiently in redesigned combustion chambers.

Scania has used a centrifuge to filter engine oil since the end of the fifties. On the 12-litre engine this was supplemented by a full-flow oil filter to extend oil-change intervals—service intervals of 6o,000krn were possible for virtually all road-going applications. A flattoothed poly-V drive belt and automatic tensioner were introduced to give a positive drive for the coolant pump, alternator and air conditioning compressor: the cooling fan with thermostat-controlled hub fitted directly into the crankshaft.

Scania's 12-speed GR900 transmission was introduced in 1991; this was consistent with the company's policy of providing synchromesh gearboxes with a direct top gear to minimise power losses. An efficient integral hydraulic retarder was added to the spec sheet in '993; Opticruise, Scania's automated transmission providing integrated control of engine, gearbox and retarder, has

been an option since the mid-nineties. Single-reduction drive axles were steadily upgraded throughout the decade to handle increasing levels of torque.

In a move towards Euro-3, a revised power line-up was launched in April 1998, with the 12-litre engine topping 42ohp. But the major change was that the new it-litre Euro-2 units at 340 and 38ohp and the 12-litre at 42ohp all came with unit injectors, replacing the in-line injection pump. The injectors were controlled by an ECU (electronic control unit) on the (cool) left hand side of the engine.

As with E DC, this control system could be integrated with other systems such as electronic brakes, stability control and adaptive cruise control. Versions meeting Euro-3 came along the following year. Most electronic systems on 4-Series had integral fault diagnostics which could be accessed in the workshop: use of a laptop computer with a Vehicle Communications Interface link ensured a fast, systematic approach to trouble shooting.

Scania says that development of its UK network is a high priority; last year it opened its 8oth service point. Many of them are open 24 hours a day.

• by Bill Brack