Triple Interest in Sound Producer-gas Conversion

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

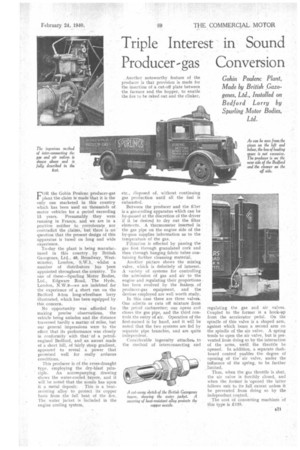

Gohin Poulenc Plant, Made by British Gazagenes, Ltd., Installed on Bedford Lorry by Spurling Motor Bodies, Ltd.

UOR the Gob in Poulenc producer-gas

plant theclaim is Made that it is the only one marketed in this country which has been Used on thousands of motor vehicles for a period exceeding 15 years. Presumably they were running in France, and we are in a position neither to .corroborate nor contradict the claims, but there is no question that the present design of this apparatus is based on long and wide experience.

To-day the plant is being manufactured in this country by British Gazogenes, Ltd., 48, Broadway, Westminster, London, S.W.1, whilst a number of distributors has been appointed throughout the country. To one of these—Spurling Motor Bodies, Ltd„ Edgware Road, The Hyde, London, N.W.9—we are indebted for the experience of a short run on the Bedford 3-ton long-wheelbase lorry illustrated, which has been equipped by this concern.

No opportunity was afforded for. making precise observations, the vehicle being unladen and the distance traversed hardly a matter of miles, but our general impressions were to the elect that its performance was closely in conformity with that' of a petrolengined Bedford, and an ascent made of a short hill, of fairly steep gradient, appeared to reveal a power that promised well for really arduous conditions. • This producer is of the cross-draught type, employing the dry-blast principle. An accompanying drawing shows the water-cooled tuyere, and it will be noted that the nozzle has upon

it a metal deposit. This is a heatresisting alloy to protect its copper basis from the full heat of the fire. The water jacket is included in the engine cooling system.

. Another noteworthy feature of the producer is that provision is made for the insertion of a cut-off plate between the furnace and the hopper, to enable the fire to he raked out and the clinker, etc., disposed of, without continuing gas production until all the fuel is exhausted.

Between the producer and the fiaer is a gas-cooling apparatus which can be by-passed at the discretion of the driver if it be desired to dry out the filter elements. A thermometer insetted in the gas pipe on the engine side of the by-pass supplies information as to the temperature of the gas.

Filtration is effected by passing the gas first through granulated cork and then through hanging fabric tubes containing further cleansing material.

Another picture shows the mixing valve, which is definitely of interest. A variety of systems for controlling the admission of gas and air to the engine and regulating their proportions has been evolved by the makers of producer-gas equipment, and the devices employed are well worth study.

In this case there are three valves. One admits or cuts off mixture from the petrol carburetter; one opens and closes the gas pipe, and the third controts the entry of air. Operation of the first-named is by hand, and it will be noted that the two systems are fed by separate pipe branches, and are quite independent.

Considerable ingenuity attaches, to the method of interconnecting and

regulating the gas and air valves. Coupled to the former is a hook-up from the accelerator pedal. On the spindle of this valve is a shaped arm, against which bears a second arm on the spindle of the air valve. A spring tends to open the air valve, but is prevented from doing so by the interaction of the arms, until the throttle be opened. In addition, a separate dashboard control enables the degree of opening of the air valve, under the influence of the spring, to be further limited.

Thus, when the gas throttle is shut, the air valve is forcibly closed, and when the former is 'opened the latter follows suit to its full extent unless it be prevented from doing so by the independent control.

The cost of converting machines of this type is £135.