A NEW TROLLEY-BUS TRAMCAR LOADS

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

AT a time when the trolley-bus is gain4ng in favour to an important degree in the municipal market for urban passenger-service vehicles, a highly advanced design of six-wheeled trolley-bus, seating no fewer than 74 persons, is introduced by the Associated Equipment Co., Ltd., Southall, in conjunction with the English Electric Co., Ltd.

Trolley-buses have hitherto afforded accommodation for 50 or 60 passengers, and this has provided one of the few remaining arguments in favour of the tramcar, namely, that it could shift tremendous peak loads from congested city areas.

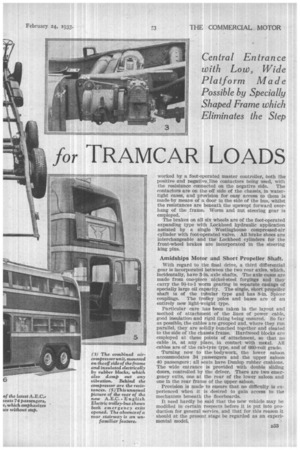

To provide for 74 seated persons as well as a number of standing passengers would be valueless unless rapid loading and unloading could be ensured, and in this case the problem has been tackled by providing a central entrance which has no step. The abolition of the step reduces hesitancy on the part of the passengers, thus Saving much time at each halt. Lowpressure 10.5-in tyres are fitted on all wheels.

The vehicle has an overall length of 30 ft. and fully laden weighs under 13 tons. By the use of specially designed electrical equipment chassis weight is brought down to 4 tons 5i cwt.

The 80 h.p. field-controlled series traction motor is located towards the, rear of the chassis, transmitting Its power through one short driving shaft. Both the motor and the air compressor used for braking are rubber mounted, and throughout special attention has been paid to insulation. For example, the resistances are doubly protected by dry-spot insulators.

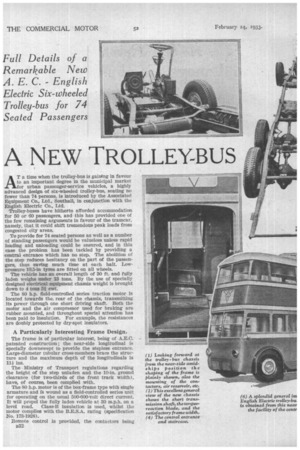

A Particularly Interesting Frame Design.

The frame is of particular interest, being of A.E.C. patented construction ; the near-side longitudinal is specially downswept to provide the stepless entrance. Large-diameter tubular cross-members brace the structure and the maximum depth of the longitudinals is Ili ins.

The Ministry of Transport regulations regarding the height of the step unladen and the 10-in, ground clearance (for two-thirds of the front track width), have, of course been complied with.

The 80 h.p. motor is of the box-frame type with single armature and is wound as a field-controlled series unit for operating on the usual 500-600-volt direct current. It will propel the fully laden vehicle at 30 m.p.h. on a level road. Class-B insulation is used, whilst the motor complies with the B.E.S.A. rating (specification No. 173-1928).

Remote control is provided, the contactors being B32 worked by a foot-operated master controller, both the positive and negative line contactors being used, with the resistance connected on the negative side. The contactors are on the off side of the chassis, in watertight cases, and provision for easy access to them is made by means of a door in the side of the bus, whilst the resistances are beneath the upswept forward overhang of the frame. Worm and nut steering gear is employed.

The brakes on all six wheels are of the foot-operated expanding type with Lockheed hydraulic application assisted by a single Westinghouse compressed-air cylinder with foot-operated valve. All brake shoes are interchangeable and the Lockheed cylinders for the front-wheel brakes are incorporated in the steering king pins.

Amidships Motor and Short Propeller Shaft,

With regard to the final drive, a third differential gear is incorporated between the two rear axles, which, incidentally, have 3-in, axle shafts. The axle cases are made from one-piece nickel-steel forgings and they carry the 9i-to-1 worm gearing in separate casings of specially large oil capacity. The single, short propeller shaft is of the tubular type and has 8-in. Spicer couplings. The trolley poles and bases are of an entirely new light-weight type.

Particular care has been taken in the layout and method of attachment of the lines of power cable, good insulation and rigid fixing being ensured. So far as possible, the cables are grouped and, where they run parallel, they are solidly bunched together and cleated to the side of the chassis frame. Hardwood blocks are employed at these points of attachment, so that no cable is, at any place, in contact with metal. All cables are of the cab-tyre type, and of 860-volt grade.

Turning now to the bodywork, the lower saloon accommodates 34 passengers and the upper saloon 40 passengers ; all seats have Dunlop rubber cushions. The wide entrance is provided with double sliding doors, controlled by the driver. There are two emergency exits, one at the rear of the lower saloon and one in the rear frame of the upper saloon.

Provision is made to ensure that no difficulty is experienced when it is desired to gain access to the mechanism beneath the floorboards.

It need hardly be said that the new vehicle may be modified in certain respects before it is put into production for general service, and that for this reason it should at the present stage be regarded as an experimental model.