DUPLICATED PROPELLER SHAFTS for Powerful Machines

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

A Method of Reducing Transmission Stresses. Two-stage Speed Reduction and Its Advantages

MODERN industrial conditions demand the rapid transport of goods at strictly economical prices ; therefore, the large vehicle must be employed for this class oi work, because the price per ton-mile decreases as the size of the vehicle employed increases. In view of this fact, there is a tendency to use goods-carrying vehicles of still larger capacity. Obviously, rear-axle ratios in machines of this class mast bo. of a fairly low order, and where worm gears are used the question arises as to the ease of over-running. In addition, there is clearance to le considered.

In a similar manner the overall dimensions of low-ratio bevel-driven axles become unwieldy, because the bevel pinion cannot be made too small and the low ratio requireemust be obtained by the use of an inconveniently large crown wheel.

Either with worm or bevel gears transmitting the torque that is necessary to propel heavy machines the tooth pressures are of a high order, and the differential assembly in a rear axle of ordinary construction has to be a massive piece of work in order to withstand the great loads to which it is stibjected at comparatively low rates of rotation.

TO overcome these dlifierdties a transmission system has been patented by Mr. J. R.. Churchill, of 6, Shoot-up Hill, London, N.W.2. We here make reference to two specific designs, but the general principle is the :same

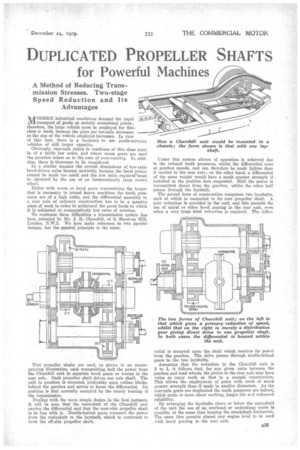

Two propeller shafts are used, as shown in an accompanying illustration, each transmitting half the power from the Churchill unit to separate bevel gears or worms in the rear axle. Each propeller shaft drives one axle shaft. The unit in question is mounted, preferably upon rubber blocks, behind the gearbox and serves to house the differential. Its position is that normally occupied by the steady bearing of the transmission.

Dealing with the more simple design in the first instance, It will be seen that the mainshaft of the Churchill unit carries the differential and that the near-side propeller shaft is in line with it. Double-helical gears transmit the power Irons the •mainshaft to the layshaft, which is continued to form the off-side propeller shaft.

Under this system silence of operation is achieved due to the reduced tooth pressures, whilst the differential runs at gearbox speeds, and can therefore be made lighter than if carried in the rear axle ; on the other hand, a differential of the same weight would have a much greater strength if installed in the position here suggested. Half the power is transmitted direct from the gearbox, whilst the other half passes through the layshaft.

The second form of construction comprises two layshafts, each of which is connected to its own propeller shaft. A gear reduction is provided in the unit, and this permits the use of spiral or other bevel gearing in the rear axle, even when a very large total reduction is required. The differ

ential is mounted upon the shaft which receives its power from the gearbox. The drive passes through double-helical gears to the two layshafts.

Assuming that the reduction in the Churchill unit is 2 to 1, it follows that, for any given ratio between the gearbox and road wheels, the pinion in the rear axle may have twice as many teeth as that in a normal construction. This allows the employment of gears with teeth of much greater strength than if made in smaller diameters. As the rear-axle gears are duplicated the tooth pressures are halved, which tends to more silent working, longer life and enhanced reliability. By arranging the layshafts above or below the mainshaft of the unit the use of an overhead or unclerslung worm is possible, at the same time keeping the crankshaft horizontal. The same idea permits almost any engine level to be used with bevel gearing in the rear axle.