BRING!

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

HONE THE

114C

• The unlikely combination of a German prisoner of war and a half-share in a pig led to the formation of one of the most progressive hauliers in the north-east of England. This year, Stiller Transport of Middleton St George, near Darlington, celebrates its 25th anniversary as a company specialising in tanker, abnormal load and general haulage. The PoW was Gunther Stiller, captured while he was stationed in Guernsey during the Second World War, and imprisoned in Teesdale, where he became involved in farm work. When he was released, with few possessions and fewer prospects, he got a job lorry driving, and that was when he bought his share in the pig.

From these small beginnings, he invested in his own truck in 1950, a former British Road Services AEC, and slowly built up a fleet and a reputation.

In 1964 Stiller Transport was incorporated, and five years later Gunther Stiller bought three acres of ground at Middleton St George; another five acres have since been added, and the site includes 3,716m2 (40,000ft2) of warehousing.

Gunther had married a local girl, and in 1980 their son Paul joined the company from a Business Studies course at Edinburgh University. Stiller senior retired in 1985 at the age of 60, and Paul became managing director after a five-year apprenticeship that had involved everything from driving a shunter at Hartlepool Docks to running Stiller's traffic office.

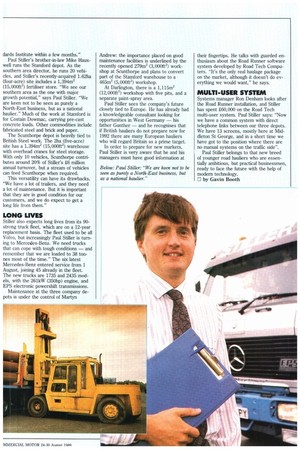

Left: Peter Heron (sitting), operations manager, and Ron Denham, systems manager, look after the company's £60,000 Road Tech multi-user system. "Long-serving members of staff were there to `keep me right'," says Paul Stiller, "and they now form the basis of our management team." Peter Heron, the company's operations director, joined S6I ler in 1966, when the fleet consisted of only five trucks.

Today, Stiller Transport operates 90 vehicles, with a fleet of more than 200 trailers, and although the head office is still at Middleton St George, there are depots at Scunthorpe and Stamford.

The proportion of trailers to trucks allows greater flexibility, and the compan: can cope with temporary slumps in any o its markets. The range of trailers is wide from standard flat-bed trailers, tippers an curtainsiders to bulk and multicompartment tankers. For abnormal and indivisible loads there is a range of extendable trailers.

The proximity of the head office to Teesside means that most of the Stiller fleet of tankers is based at Middleton St George, principally transporting chemical! for ICI and fuel for Phillips Petroleum.

The ICI work involves the transport of moderately hazardous substances, mainly bulk liquid chemicals for the fertiliser industry. These include ammonium nitrate Liquor, methanol and phenols, but Stiller can handle anything suitable for stainless steel tankers.

Working for ICI involves a substantial commitment to quality for Stiller. "Its ow quality standards are based on BS5750, and ICI expect its suppliers to work towards this same standard," says Paul Stil ler. "For us this means a more discipline! approach to the business, involving the setting of quality standards, preparation manuals, and training for drivers in the handling of hazardous loads. We hope to have accreditation for the British Stan dards Institute within a few months."

Paul Stiller's brother-in-law Mike Hauxwell runs the Stamford depot. As the southern area director, he runs 20 vehicles, and Stiller's recently-acquired 1.62ha (four-acre) site includes a 1,394m2 (15,000ft2) fertiliser store. "We see our southern area as the one with major growth potential," says Paul Stiller. "We are keen not to be seen as purely a North-East business, but as a national haulier." Much of the work at Stamford is for Costain Dowmac, carrying pre-cast concrete loads. Other commodities include fabricated steel and brick and paper.

The Scunthorpe depot is heavily tied to British Steel work. The 2ha (five-acre) site has a 1,394m2 (15,000ft2) warehouse with overhead cranes for steel storage. With only 10 vehicles, Scunthorpe contributes around 20% of Stiller's 26 million annual turnover, but a stream of vehicles can feed Scunthorpe when required.

This versatility can have its drawbacks. "We have a lot of trailers, and they need a lot of maintenance. But it is important that they are in good condition for our customers, and we do expect to get a long life from them."

Stiller also expects long lives from its 90strong truck fleet, which are on a 12-year replacement basis. The fleet used to be all Volvo, but increasingly Paul Stiller is turning to Mercedes-Benz. We need trucks that can cope with tough conditions — and remember that we are loaded to 38 tonnes most of the time." The six latest Mercedes-Benz entered service from 1 August, joining 45 already in the fleet. The new trucks are 1735 and 2435 models, with the 261kW (350hp) engine, and EPS electronic powershift transmissions.

Maintenance at the three company depots is under the control of Martyn

Andrew: the importance placed on good maintenance facilities is underlined by the recently opened 279m2 (3,000ft2) workshop at Scunthorpe and plans to convert part of the Stamford warehouse to a 465m2 (5,000ft2) workshop. At Darlington, there is a 1,115m2 (12,000ft2) workshop with five pits, and a separate paint-spray area.

Paul Stiller sees the company's future closely tied to Europe. He has already had a knowledgeable consultant looking for opportunities in West Germany — his father Gunther — and he recognises that if British hauliers do not prepare now for 1992 there are many European hauliers who will regard Britain as a prime target.

In order to prepare for new markets, Paul Stiller is very aware that he and his managers must have good information at their fingertips. He talks with guarded enthusiasm about the Road Runner software system developed by Road Tech Computers. "It's the only real haulage package on the market, although it doesn't do everything we would want," he says.

Systems manager Ron Denham looks after the Road Runner installation, and Stiller has spent 260,000 on the Road Tech multi-user system. Paul Stiller says: "Now we have a common system with direct telephone links between our three depots. We have 13 screens, mostly here at Middleton St George, and in a short time we have got to the position where there are no manual systems on the traffic side".

Paul Stiller belongs to that new breed of younger road hauliers who are essentially ambitious, but practical businessmen, ready to face the future with the help of modern technology.

0 by Gavin Booth