DIESEL MILESTONE

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

Electronically-controlled fuel injection is the next important phase in diesel engine development, and Detroit Diesel Allison is ahead of the field for commercial applications. Tim Blakemore reports

IESEL engines of the future will have electronically controlled fuel injection. I have yet to meet an engineer from any engine or fuel injection equipment (fie) manufacturer who would disagree with that statement.

This is a logical next step in the continuing refinement of ci (compression ignition) engines. But the questions remain: when and how?

In 1978 Rolls-Royce V12 military engines began to use a Lucas CAV electronic injection control system. More recently the two major suppliers of fie in Europe, Lucas and Bosch, have displayed prototypes of electronically controlled components at shows. One is the interesting Lucas CAV unit injector for small, high-speed, direct-injection engines, which was unveiled at the 1983 Frankfurt show.

At last year's Society of Automotive Engineers congress in Detroit, Stanadyne Diesel Systems of the USA displayed two versions of a system which, it claimed, could be in limited production for some 1986 engines.

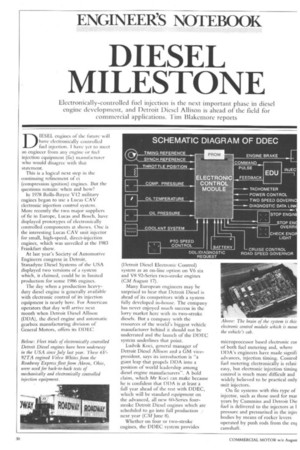

The day when a production heavyduty diesel engine is generally available with electronic control of its injection equipment is nearly here. For American operators that day will arrive next month when Detroit Diesel Allison (DDA), the diesel engine and automatic gearbox manufacturing division of General Motors, offers its DDEC (Detroit Diesel Electronic Control) system as an on-line option on V6 six and V8 92-Series two-stroke engines (CM August 17).

Many European engineers may be surprised to hear that Detroit Diesel is ahead of its competitors with a system fully developed in-house. The company has never enjoyed much success in the lorry market here with its two-stroke diesels. But a company with the resources of the world's biggest vehicle manufacturer behind it should not be underrated and the launch of the DDEC system underlines that point.

Ludvik Koci, general manager of Detroit Diesel Allison and a GM vicepresident, says its introduction is "a giant leap that propels DDA into a position of world leadership among diesel engine manufacturers". A bold claim, which Mr Koci can make because he is confident that DDA is at least a full year ahead of the rest with DDEC, which will be standard equipment on the advanced, all new 60-Series fourstroke Detroit Diesel engines which are scheduled to go into full production next year (CM June 8).

Whether on four or two-stroke engines, the DDEC system provides microprocessor based electronic cor of both fuel metering and, where DDA's engineers have made signifi advances, injection timing. Control fuel metering electronically is relati• easy, but electronic injection timinp control is much more difficult and widely believed to be practical only unit injectors.

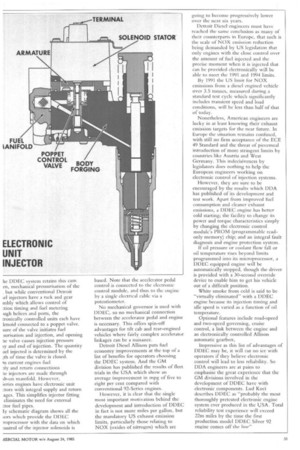

On fie systems with this type of injector, such as those used for mar years by Cummins and Detroit Die fuel is delivered to the injectors at 1 pressure and pressurised in the injec bodies by means of rocker levers operated by push rods from the enE camshaft. he DDEC system retains this cam en, mechanical pressurisation of the but while conventional Detroit ;el injectors have a rack and gear mbly which allows control of :tion timing and fuel metering ugh helices and ports, the

tronically controlled units each have lenoid connected to a poppet valve. sure of the valve initiates fuel surisatic-in and injection, and opening he valve causes injection pressure ry and end of injection. The quantity ael injected is determined by the ;th of time the valve is closed. In current engines fuel

31y and return connections le injectors are made through iit-on manifold. However, ;cries engines have electronic unit :tors with integral supply and return ages. This simplifies injector fitting eliminates the need for external :tor fuel pipes.

ly schematic diagram shows all the ;ors which provide the DDEC roprocessor with the data on which ;ontrol of the injector solenoids is based. Note that the accelerator pedal control is connected to the electronic control module, and thus to the engine by a single electrical cable via a potentiometer.

No mechanical governor is used with DDEC, so no mechanical connection between the accelerator pedal and engine is necessary. This offers spin-off advantages for tilt cab and rear-engined vehicles where fairly complex accelerator linkages can be a nuisance.

Detroit Diesel Allison puts fuel economy improvements at the top of a list of benefits for operators choosing the DDEC system. And the GM division has published the results of fleet trials in the USA which show an average improvement in mpg of five to eight per cent compared with conventional 92-Series engines.

However, it is clear that the single most important motivation behind the development and introduction of DDEC in fact is not more miles per gallon, but the mandatory US exhaust emission limits, particularly those relating to NOX (oxides of nitrogen) which are going to become progressively lower over the next six years.

Detroit Diesel engineers must have reached the same conclusion as many of their counterparts in Europe, that such is the scale of NOX emission reduction being demanded by US legislation that only engines with the close control over the amount of fuel injected and the precise moment when it is injected that can be provided electronically will be able to meet the 1991 and 1994 limits.

By 1991 the US limit for NOX emissions from a diesel engined vehicle over 3.5 tonnes, measured during a standard test cycle which significantly includes transient speed and load conditions, will be less than half of that of today.

Nonetheless, American engineers arc lucky in at least knowing their exhaust emission targets for the near future. In Europe the situation remains confused, with still no firm acceptance of the ECE 49 Standard and the threat of piecemeal introduction of more stringent limits by countries like Austria and West Germany. This indecisiveness by legislators does nothing to help the European engineers working on electronic control of injection systems.

However, they are sure to be encouraged by the results which DDA has published of its development and test work. Apart from improved fuel consumption and cleaner exhaust emissions, a DDEC engine has better cold starting; the facility to change its power and torque characteristics simply by changing the electronic control module's PROM (programmable readonly memory) chip; and an integral fault diagnosis and engine protection system.

If oil pressure or coolant flow fall or oil temperature rises beyond limits programmed into its microprocessor, a DDEC equipped engine will be automatically stopped, though the driver is provided with a 30-second override device to enable him to get his vehicle out of a difficult position.

White smoke from cold is said to be "virtually eliminated" with a DDEC engine because its injection timing and idle speed is varied as a function of oil temperature.

Optional features include road-speed and two-speed governing, cruise control, a link between the engine and an electronically controlled Allison automatic gearbox.

Impressive as this list of advantages of DDEC may be, it will cut no ice with operators if they believe electronic control will lead to less reliability. So DDA engineers are at pains to emphasise the great experience that the GM divisions involved in the development of DDEC have with electronic components. Lud Koci describes DDEC as "probably the most thoroughly pretested electronic engine system ever produced in the USA. Total reliability test experience will exceed 22m miles by the time the first production model DDEC Silver 92 engine comes off the line"