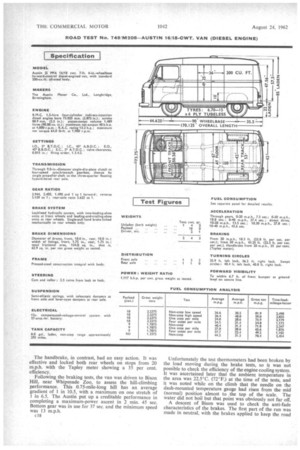

ROAD TEST: B.M.C. (Austin) 16/18-cwt. diesel van

Page 44

Page 45

Page 46

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

DIESEL SHOWS UP WELL

By A. J. P. Wilding IT is now just over six years since B.M.C. introduced the Austin 152 and Morris J2 15-cwt, rangeSince then there have been a number of changes in the design—some relating to the body, but the most important have been the increase in the load rating from 15 to 18 cwt. and the change from a steering-column-. to a floormounted gear lever. There is also now the option of a B.M.C. 1.5-litre diesel engine in place of the standard petrol engine of the same capacity.

The van tested was of the latest design and had the diesel engine fitted. This unit has bore and stroke dimensions of 2.875 in. and 3.5 in. respectively, identical to those of the standard petrol engine. The diesel's maximum net power output of 40 b.h.p. is only 2 b.h.p. less than that of the petrol engine, both being obtained at 4,000 r.p.m. Maximum net torque is 64 lb.-ft. for both engines—at 2,000 r.p.m. for the petrol, at 1,900 for the diesel. It follows therefore, that with the same gross vehicle weight and final drive ratios the performance with the diesel engine should be only a little poorer than that obtained with the petrol unit.

Apart from the engine, the mechanical specification of the van which was the subject of this test was virtually identical to that of the Morris .12 reported on in The Commercial Motor of July 27, 1956. Because of the extra

load carried in the 18 cwi model and the higher kerb weight it was not possible to compare directly the results of the two tests to ascertain the effect of the diesel engine on performance and—more important—fuel consumption. As I was to carry out the test alone, the van was loaded with 16.5 cwt. of iron weights and 1.5 cwt. of sand to give the full I8-cwt. rated load applicable when there is no passenger. The load was placed centrally in rows down the full length of the body floor to give the effect of an equally distributed load.. Gross laden weight was 2 ton 4 cwt. 3 qr. (the 1956 vehicle weighed 2 ton 1 cwt. 2 qr.). In this condition the front axle carried 1 ton 3 cwt. 3 qr. and the rear axle 1 ton 1 cwt. The whole of the additional 3 cwt. I qr. was found to be added to the load on the front axle. All tests, with the exception of the part-load fuel consumption tests, were carried out at this recorded gross weight.

Fuel consumption tests were carried out on the 6-mile out-and-return run along A6 between Barton and nophill. At the time of the tests, the ambient temperature was 16.5°C. (62'F.) and there was no wind to speak of—ideal conditions in fact. The results obtained were excellent for a van carrying an 18-cwt. load and were, on average, some 18 per cent, better than those obtained with the petrol-engined van (3-cwt. lighter) in 1956.

The van did not fed underpowered, and this was confirmed by the results. The fuel consumptions on the fourstops-per-mile runs for partand full-load were closer than those for the non-stop runs in the two load conditions. The oneand four-stops-per-mile tests are designed to simulate delivery work. Each of the stops was of 15 seconds duration, during which time the engine was left idling, the

average speed quoted being based on the time the vehicle was actually on the move. Acceleration figures obtained on the test were commendable, the times being only a little longer than the average for 15-cwt. vans. The B.M.C. 1.5-litre diesel gives useful torque at low revs., and there was reasonable pull-away from 10 m.p.h. on the direct-drive runs.

Maximum-pressure brake-test stops from 20 m.p.h. were completed first. The van was perfectly stable and the figures obtained were satisfactory for a van of this type—the average stopping distance was 20.8 ft. and the maximum deceleration on the stops, as recorded with a Tapley meter. was 90 per cent. On the stops from 30 m.p.h., however, all the wheels except the nearside front locked (the nearside front tyre marked the road slightly) and the front of the van swung violently across the road. Skid marks measuring over half the total stopping distance were left behind the van on each .stop. The average stopping distance from the higher speed was 52.8 ft., although the maximum deceleration shown by the Tapley meter was 93 per cent.

An Improvement To ascertain whether this result was due to a maladjustment on the test vehicle or to a basic design fault, brake tests were carried out on the same vehicle a month later, after servicing (including brake adjustment) by B.M.C.

On the second tests the van behaved perfectly and the figures quoted in the data panel were obtained (18.3 ft. from 20 m.p.h. and 43.25 ft. from 30 m.p.h.). All the wheels locked on the stops from both speeds and the front of the van deviated only 18 in. or so from the straight line. This time the movement was to the nearside.

An extremely high pedal effort was required, even for relatively light braking when fully loaded. I had to use my instep instead of the ball of my foot to depress the pedal, so as to obtain the necessary effort. At the end of eight hours' driving, my right leg muscles were unusually tired. The fault was not solely because so much force was needed at the pedal but partly through the pedal itself being set high in relation to the seat, which in my case meant that the pressure had to be applied with my knee bent at almost 90. The handbrake, in contrast, had an easy action. It was effective and locked both rear wheels on stops from 20 m.p.h. with the Tapley meter showing a 35 per cent. efficiency.

Following the braking tests, the van was driven to Bison Hill, near Whipsnade Zoo, to assess the hill-climbing performance. This 0.75-mile-long hill has an average gradient of I in 10.5, with a maximum on one stretch of 1 in 6.5. The Austin put up a creditable performance in completing a maximum-power ascent in 2 min. 45 sec. Bottom gear was in use for 37 sec. and the minimum speed was 13 m.p.h.

C18 Unfortunately the test thermometers had been broken by the load moving during the brake tests, so it was not possible to check the efficiency of the engine cooling system. It was ascertained later that the ambient temperature in the area was 22.5°C. (72°F.) at the time of the tests, and it was noted while on the climb that the needle on the dash-mounted temperature gauge had risen from the mid (normal) position almost to the top of the scale. The water did not boil but that point was obviously not far off. A descent of Bison was used to check the anti-fade characteristics of the brakes. The first part of the run was made in neutral, with the brakes applied to keep the road

speed at 20 m.p.h. Near the bottom of the hill, where the gradient becomes less steep, top gear was engaged and full throttle applied with the brakes still on to restrict the • speed to 20 m.p.h. Total time for the descent was 2 min. 24 sec., of which 34 sec. were spent in top gear. . At the bottom a full-pressure footbrake stop from 20 m.p.h. produced a Tapley meter reading of 56 per cent. The drop of 34 per cent. on the earlier brake tests showed appreciable fade and this must have been due to the lining material, because there was no discernible increase in the brake pedal travel.

On the journey to the fuel consumption test route, the M I motorway was used. The speedometer was checked and found to be accurate at 30 m.p.h. and 50 m.p.h., and the maximum speeds in the four gears were 15, 23, 37 and 55 m.p.h. The motorway was used on the run home to obtain the high-speed fuel consumption. The 10.6-mile stretch south from the A505 to the A4147 junctions was again used and a creditable consumption of 26.4 m.p.g. Was returned at an average speed of 48 m.p.h.

For almost all the time on the motorway the van was at or near its maximum speed of 55 m.p.h., at which speed it handled very well. On a very rough section of theJlearside lane approaching the A6 junction, the steering remained controllable at high speed, and the suspension stood up to the strain remarkably well. The suspension was found to be very good over all types of road surface.

At normal speeds, however, the steering was not of the .same standard as the suspension. No doubt, when the

• model waS first introduced in 1956, the steering action was up to the then currently acceptable standard, but it has not been brought into line with what I would consider desirable nowadays. Obviously the additional 3.25 cwt.

• on the front axle did not help. The steering was excessively heavy and I found it necessary to make almost constant steering correction to keep a straight course when running below about 20 m.p.h. At high speeds the van was perfectly well behaved, as I said earlier, but the overall impression was of driving a much heavier vehicle. The servicing before the brake re-test had presumably 'included greasing the steering linkage, as the wandering tendency had diminished and control was a little -lighter.

• Although hard work, the 12 was manceuvrable in traffic and confined spaces, being helped by a good driving position, excellent visibility and well-placed exterior mirrors. The change from a steering-columnto a floorMounted gear change is a distinct improvement, but it • took a little time to get used to the reversed gate. The reverse gear position could well be protected by a stronger spring stop for, occasionally, on 'changes down from third to second it was possible to override the stop and crash reverse gear.

In general, the B.M.C. 1.5-litre diesel engine was good by small diesel standards. Tickover was smooth, it was reasonably lively and it started easily. It is not possible to pass an opinion on the cold-starting capabilities, as the lowest ambient temperature at which the engine was started after standing overnight was about 10°C. '(50°F.). No difficulty was experienced when the heater plugs were brought into use before turning the engine. Because no extra sound insulation is provided when the diesel engine is fitted, and because the engine's revs, had to be used to get adequate performance to keep up with traffic, the noise level inside the van was high. Some form of insulation is needed.

A full series of maintenance tests was carried out on the van, some duplicating those done on the 1956 test, but there are slight variations in the layout of auxiliary units with the diesel engine fitted. Removing the bonnet top to check the level of coolant in the radi ator took 7 sec., but refitting the part took 23 sec. because it was not a good fit. With the top off, the coolant level was checked in 8 sec. Access to the engine dipstick is through a trap below the driver's seat. A check of the engine oil level did not present any difficulties and occupied 52 sec. Checking the gearbox oil level was also fairly straightforward. A small trap in the main body near the front bulkhead gives access to the gearbox dipstick and the level of oil was checked in 1 min. 18 sec. A cheek of the rear axle oil level was also easy and, when the correct key had been obtained, to remove and replace the square-socketed plug took only 56 sec. A plate pivoted at its centre and held in place by a screw covers two holes in the cab floor which gives access to the brake and clutch fluid reservoirs. The two levels were checked in one operation in 1 mm. 45 sec.

A larger battery is employed on the diesel-engined van and it is mounted behind the mate's seat, instead of under the driver's seat as on the petrol-engined model. A check of the electrolyte level in the six cells took 2 min. As on the petrol-engined van, the mate's seat and the trap under neath it have to be removed to get at the engine air cleaner. The routine task of checking the level of oil in the unit was started but had to be abandoned when it was found that a clamp ring holding the fabricated outlet in place on top of the cleaner had been fitted on this particular vehicle in such a way that it could not be loosened without removing the battery and its carrier bracket.

Trouble was also experienced in carrying out brake adjustments. The ratchet-screw jack supplied in the tool kit was used and one side of the van raised by utilizing the centre jacking pad on the body sub-frame. The van was fully laden at the time and after 2 min. 15 sec. the jack was fully extended with the rear tyre still on the ground. It would not have been possible to pack up the jack before starting the lift. When fully extended the jack did not look safe -the smaller diameter lifting screw was slightly bent and the load appeared too much for it—so I decided not to risk having the jack collapse and used a trolley jack. Brake adjustment has been made easier since 1956, when the wheels had to be removed to reach internal adjusters. External adjusting nuts are now mounted on the backplate—as is the general practice. Using the trolley jack, adjustment of the front brakes took 2 min. 55 sec., whilst the rears occupied 4 sec. less.

The maintenance tasks carried out were made more difficult by the tack of an adequate tool kit with the van.

Apart from the jack and operating-rod, a wheel-nut brace and the starting handle, the only contents were a piece of rubber tube and a spanner for bleeding the brakes and a small piece of square steel bar. I cannot see the importance of supplying a brake-bleeding kit, and the square bar which fits the square-socketed drain and level plugs is not much use without something to turn it with.

Tools required to do the maintenance tests included a spanner for brake adjustment, a Philips-headed screwdriver to remove two cover plates. a box spanner for the brake and clutch master-cylinder caps, and a level-plug spanner.