BUSIER TIME

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

r CANNERS' FLEET By Alan Smith FOOD wholesalers have become chary of carrying big stocks, because of the credit squeeze, and demand that supplies come in frequent small lots. For Lincolnshire Canners, Ltd., who own two canning factories at Boston and King's Lynn and operate 30 Seddon vehicles with Perkins P6 engines, this has meant that customers who previously received monthly consignments must now be called on . weekly. The number of calls made on each delivery round has increased accordingly, together with the amount of administrative work involved in distribution.

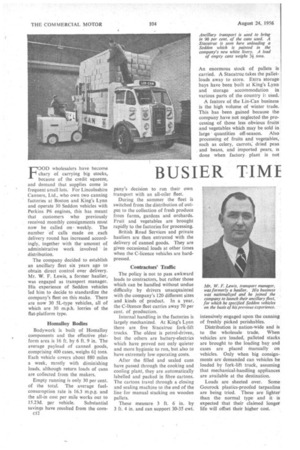

The company decided to establish an ancillary fleet six years ago to obtain direct control over delivery. Mr. W. F. Lewis, a former haulier, was engaged as transport manager. His experience of Seddon vehicles led him to decide to standardize the company's fleet on this make. There are now 30 5L-type vehicles, all of which are 30 m.p.h. lorries of the flat-platform type.

Homalloy Bodies

Bodywork is built of HomaIloy components and the effective platform area is 16 ft. by 6 ft. 9 in. The average payload of canned goods, comprising 400 cases, weighs 64 tons. Each vehicle covers about 880 miles a week, mostly with diminishing loads, although return loads of cans are collected from the makers.

Empty running is only 30 per cent. of the total, The average fuelconsumption rate is 16.3 m.p.g. and the all-in cost per mile works out to 15.23d. per vehicle. Substantial savings have resulted from the comet 2 pany's decision to run their own transport with an all-oiler fleet.

During the summer the fleet is switched from the distribution of output to the collection of fresh produce from farms, gardens and orchards. Fruit and vegetables are brought rapidly to the factories for processing.

British Road Services and private hauliers are then entrusted with the delivery of canned goods. They are given occasional loads at other times when the C-licence vehicles are hardpressed.

Contractors' Traffic

The policy is not to pass awkward loads to contractors, but rather those which can be handled without undue difficulty by drivers unacquainted with the company's 120 different sizes and kinds of product. In a year, the C-Iicence fleet carries away 70 per cent. of production.

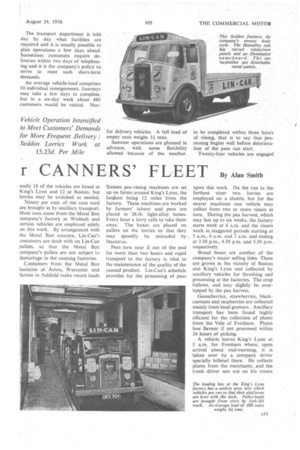

Internal handling in the factories is largely mechanized. At King's Lynn there are five Stacatruc fork-lift trucks. The oldest is petrol-driven, but the others are battery-electrics which have proved not only quieter and more hygienic to run, but also to have extremely low operating costs.

After the filled and sealed cans have passed through the cooking and cooling plant, they are automatically labelled and packed in fibre cartons. The cartons travel through a closing and sealing machine to the end of the line for manual stacking on wooden pallets.

These measure 3 ft. 6 in. by 3 ft. 4 in, and can support 30-35 cwt. An enormous stock of pallets is carried. A Stacatruc takes the palletloads away to store. Extra storage bays have been built at King's Lynn and storage accommodation in various parts of the country is used.

A feature of the Lin-Can business is the high volume of winter trade. This has been gained because the company have not neglected the processing of those less obvious fruits and vegetables which may be sold in large quantities off-season. Also processing of fruits and vegetables, such as celery, carrots; dried peas . and beans, and imported pears, is done when factory plant is not intensively engaged upon the canning of freshly picked perishables.

Distribution is nation-wide and is to the wholesale trade. When vehicles are loaded, palleted stacks are brought to the loading bay and cases are placed manually on vehicles. Only when big consignments are demanded can vehicles be loaded by fork-lift truck, assuming that mechanical-handling appliances are available at the destination.

Loads are sheeted over. Some Gourock plastics-proofed tarpaulins are being tried. These are lighter than the normal typeand it is expected that their claimed longer life will offset their higher cost.

The transport department is told day by day what facilities are required and it is usually possible to plan operations a few days ahead. Sometimes customers require deliveries within two days of telephoning and it is the company's policy to strive to meet such short-term demands.

An average vehicle-load comprises 10 individual consignments. Journeys may take a few days to complete, but in a six-day week about 480 customers would be visited. Nor malty 18 of the vehicles are based at King's Lynn and 12 at Boston, but lorries may be switched as needed.

Ninety per cent. of the cans used are brought in by ancillary transport. Most cans come from the Metal Box company's factory at Wisbech and certain vehicles are employed solely nn this work. By arrangement with the Metal Box concern, Lin-Can's containers are dealt with on Lin-Can pallets, so that the Metal Box company's pallets are not subject to demurrage in the canning factories.

Containers from the Metal Box factories at Acton,' Worcester and Sutton in Ashfield make return loads

for delivery vehicles. A full load of empty cans weighs 3+ tons.

Summer operations are planned in advance, . with some flexibility allowed because of the weather.

Sixteen pea-vining machines are set up on farms around King's Lynn, the faribbest being 12 miles from the factory. These machines are worked by farmers' labour and peas are placed in 28-1b. light-alloy boxes. Every hour a lorry calls to take them away. The boxes are placed on pallets on the lorries so that they may speedily be unloaded by Stacatruc.

Peas turn sour if out of the pod for more than two hours and rapid transport to the factory is vital to the maintenance of the quality of the canned product. Lin-Can's schedule provides for the processing of peas to be completed within three hours of vining, that is to say that processing begins well before deterioration of the peas can start.

Twenty-four vehicles are engaged upon this work. On the run to the farthest viner two lorries are employed on a shuttle, but for the nearer machines one vehicle may collect from two or more viners in turn. During the pea harvest, which may last up to six weeks, the factory starts work at 6 a.m. and the viners work in staggered periods starting at 5 a.m., 6 a.m. and 7 a.m. and ending at 3.30 p.m., 4.30 p.m. and 5.30 p.m. respectively.

Broad beans are another of the company's major selling lutes. These are grown in the vicinity of Boston and King's Lynn and collected by ancillary vehicles for threshing and processing at the factories. The crop follows, and may slightly be overlapped by the pea harvest.

Gooseberries, strawberries, blackcurrants and raspberries are collected mainly from local growers. Ancillary transport has been found highly efficient for the collection of plums from the Vale of Evesham. Plums lose flavour if not processed within 24 hours of picking.

A vehicle leaves King's Lynn at 5 a.m. for Evesham where, upon arrival about mid-morning, it is taken over by a company driver specially billeted there. He collects plums from the merchants, and the trunk driver sets out on his return run to arrive at 7-8 a.m. the next day.

This system costs more than hiring transport, but is justified by the absence of waste and the avoidance of late arrival of loads which, as indicated, involves deterioration of the fruit.

A particularly interesting costing system is followed. That it resembles those used by some hauliers is perhaps no accident, having regard, to Mr. Lewis' previous connection.

Each vehicle has a monthly cost and earning sheet. On one side are listed the various expenses incurred and on the other the Road Haulage Association's recommended rates for work done.

The difference between the two totals shows the savings attributable to ancillary operation, on the assumption that the R.H.A. rates would have been paid to outside contractors if a C-licence fleet were not used. Drivers' bonuses are based on these savings. A six-year life is reckoned upon for each vehicle, but depreciation is taken at 25 per cent. a year for four years with a nominal allowance for the remaining two.

Tyres are expected to last for a year. Drivers look after them , because longer life means bigger bonuses. Michelin Metallic tyres were found to bring vehicles into the 20 m.p.h. class, but some Michelin X covers on rear wheels give exceptionally long wear.

Engines are decarbonized at 50,00060,000 miles and new pistons with chromium top rings and Wellworthy Duaflex bottom rings are fitted, together with new valves. After a similar per iod a reconditioned Perkins engine is installed which lasts the vehicle until disposal is due, with an intermediate routine as described. Mobiloil S.A.E. 20 oil is used in all seasons.

In collaboration with F. Perkins, Ltd., an engine was run on a low viscosity lubricant. At 50,000 miles, 0.0075 in. wear was measured at the tops of the bores and 0.005 in. an inch down. This was little different from the results of using S.A.E. 20 lubricant.

Atomizers are changed at -10,000 miles. At 50,000 miles it is the practice to change the differential side bearings. Practically no rearaxle troubles have ever been experienced. Vehicles are washed after every journey. Cellulose finish eases cleaning. There is a weekly greasing and a monthly overhaul.

Driver comfort • is studied: each vehicle has a heater and demister and foglight. The newest lorry has 1-ft. 6-in.-deep valance panels to enhance appearance and is painted white. Illuminated nameboards are placed above the cab and at the rear. The first replacement vehicles are now being delivered. They are 12 Seddons with Homalloy cabs having curved windscreen panels.