For DRIVERS, MECHANICS & FOREMEN

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to the sender of any letter which we publish on this page, and an EXTRA FIVE SHILLINGS to the sender of the one which we select as being the best each week, ' All notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith, Address, .D., M. a:id F., "The Commercial Motor," 7-15, Bosebery Avenue, London, E.G. 1.

Lamps Alight.

On Saturday, August 28th, light your lamps at 8.24 in London, 8.48 in Edinburgh, 8.44 in N ewcastle, 8.41 in Liverpool, 8.32 in Birmingham, 8.34 in Bristql, and 9.24 in Dublin.

Eliminating Crankshaft End Play.

Tire sender of the following communication, has been . awarded the extra payment of 5s. this week.

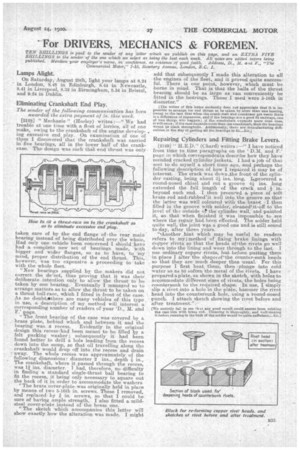

[212] " Mechanic" (Holley) writes:—" We • had trouble at one time with a fleet of lorries, all of one make, owing to the crankshaft of the engine developink excessive end play. On examination of one of 'them I discovered that the crankshaft was carried In five bearings, all in the lower half of the crankcase. The design was such that end thrust was only

taken care of by the end flange of the rear main bearing instead of being distributed over the whole, Had only one vehicle been concerned I should have had a complete new set of bearings made, With bigger and wider flanges, so as to have, to My mind, proper distribution of the end thrust. This, however, was too expensive a proceeding to take with the whole fleet.

"New bearings supplied by the makers did not correct the de'ect, thus 'proving that it was their deliberate intention only to allow the thrust tO be taken by one bearing. Eventually I managed so to arrange matters as to allow the thrust to be taken on a thrust ball-race, which I fitted in front of the case. As no doubtAthere are many vehicles of this type in use, a description of my method will interest a corresponding number of readers of your 'D., M. and F.' page. ,

"The front bearing of the ease was' covered by a brass plate, behind which and between it and the hearing WW1. a recess. Evidently in the original design this recess, had been meant to be filled INT a felt packing washer ; subsequently it had been found better to drill a hole leading from the recess down into the sump, so that oil travelling along the crankshaft would drop off into the :recess and drain away. The whole recess was approximately of the following dimensions: diameter 2 ins., depth in., The crankshaft, where it passed through the recess, was 1 ins. diameter. I had, therefore, no difficulty in finding a. standard single-thrust ball bearing to fit the recess, it being only necessary to square out the back of it in order to accommodate the washers "The brass cover-plate was originally held in place by means of two 5-16th in. screws. These I removed,

and replaced by in. screws, so that I could be sure of having ample strength. I also fitted a mildsteel cover-plate instead of the brass one. "The sketch which acconmanies this letter will show exactly how the alteration was made. I might

add that subsequently Imade this alteration to all the 'engines of the fleet,. and it proved quite successful. There is one point, however, which must be borne in mind. That is that the illas of the thrust bearing, should be as large as can conveniently be -fitted in the bearings. Those I used were 5-16th in diameter."

[The writer of thie letter evidently does not appreciate that it is impossible to arrange for end thrust to be taken by more than one bearing, owing to the fact that when the crankshaft and crankcase get warm there. is a difference of expansion, and if the bearings are a good ht endways, one of two things wili happen ; if the crankshaft expands More than -ease, it will seize ; if the case expands more than the crankshaft, then the bearings would be slack throughout. Additionally, there are manufacturing difficulties in the way of getting au the bearings to fit._En.] Repairing Cylinders and Fitting Brake Levers.

[2129] " H.E.D." (Chard) writes :—" I have noticed from time to time paragraphs on the D.M. and F.' page in which correspondents deaeribe how they have mended cracked cylinder jackets. I had a job of that sort to do myself a, short time ago, and perhaps the following description of howl repaired it may be of interest. The crack was doWn,the front of the cylinder casting, being about 3i ins. king. Lprocured round-nosed chisel and cut a groove '4?2 ins, long extended the full length of the crack and beyond each end. I then procured a piece of soft brass-rod andirubbed'it Well into the groove so that the latter was well coloured with the•brasq. . I then filled in the groove with solder, cleanedqt-off to:the level of thi outside ot the cylinder wall, and painted it, so that when finished it was impossible to ,see where the repair had been effected. The solder held quite well, the joint was a good (:).ne and is still soimel today, after three years. 'Another hint which may be useful to readers refers to mylmethod of fixing brake linings with copper rivets so that the heads op-the rivets go well down into the lining and wear through to the last. I use ordinary copper rivets, but before putting 'them in place I alter the shapefoPthe counter-sunk heads so that they aremuch deeper than 'usual.For this purpose I first heat them, then plunge into cold water so as to soften the metal Of the rivets. I have prepared a plate, as shown in the sketch, with holesto accommodate different sizes of rivets, the holes being countersunk to the required shape. In use, I simply slip a rivet-into a hole in the plate, hammer the rivet head into the 'countersunk hole, using a tound-nosed punch. I attach sketch showing the rivet before and after treatment." .

[We entirely fel to see thst any good result could accrue from rubbingthe met iron with brass rod. Cleaning It thoroughly, and well-tinning it before running in the bulk of the solder would be quite sufficient.—En. I