15 m.pig

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

ith New Dodge :onner

By Laurence J. Cotton, M.I.R.T.E.

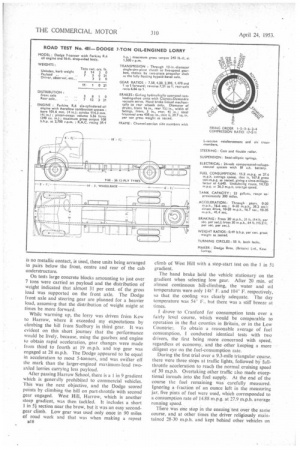

THIS week The Commercial Motor is able to publish a full description and road-test report of a new Dodge 7-ton oil-engined lorry which, carrying a generous payload, afforded unusually economical fuel returns on flat and undulating routes and climbed a short 1 in 54 gradient in second gear. Complete with a 16-ft. drop-sided body and full tank, it weighs 3 tons 144 cwt. and is rated for a maximum

gross vehicle weight of 11 tons 3 cwt. It is being produced at a competitive price, the chassis costing £1,355 and with cab £1,423 plus 1267 I 1 s. 9d. tax.

The Dodge 7-ton forward-control model was first introduced with a petrol engine at the Commercial Motor Show last year and was a tentative measure before the production of the oil-engined version. Features of the latest model include 9.00-20-in. tyres, high-speed oil engine, all-metal cab, hydraulically operated braking with vacuum assistance, and heavyduty frame, steering and transmission components. If operated at the weight specified by the makers, the Dodge. is equal in payload capacity to models of the maximum-load class in Britain, and with the standard tyre equipment, its payload is unaltered in countries where the American T.R.A. schedule applies.

The Perkins R.6 high-speed oil engine (The Commercial Motor, April 10), when fitted in the chassis with exhauster, fan and dynamo connected, has a net output of 101 b.h.p. at 2,700 r.p.m., and is installed in the Dodge on a four-point mounting. At the front it is supported on two rubberbonded units in shear and compression and inclined at an angle, so that the main axes, when projected, intercept slightly above the line of oscillation.

The two rear supports are mounted at an angle to the vertical, so that oscillation of the unit is constrained about the normal axis through the centre of gravity of the engine and centre line of the propeller-shaft front universal joint. Movement of the engine from torque reaction is limited by a separate rubber buffer.

A Borg and Beck 13 in.-diameter clutch, with springloaded centre plate and segment facings, is employed, and the Dodge five-speed direct-drive-top gearbox is attached as a unit with the engine. This gearbox is common to the petrol-engined version, but as the Perkins unit is governed to 2,700 r.p.m., there is a less perceptible gap in the gear-ratio Spacing than might normally be apparent when an engine is set at a lower maximum speed.

A heavy-duty hypoid-bevel rear axle of 6.66 to 1 is standard for the 7-tonner, but an Eaton two-speed unit is available as an alternative. With the single-ratio axle installed, the Dodge reached over 45 m.p.h. on level ground during my trials, but the high ratio of the two-speed unit would afford a maximum speed of about 55 m.p.h.

Brake gear for this model includes a Clayton Dewandre 175 mm. vacuum-servo motor, and Girling hydraulically operated two-leading-shoe units. The servo motor is attached to the frame close to the brake pedal, and the cylindrical vacuum reservoir is located adjacent to the fuel tank on the near side of the chassis. Dual hydraulic cylinders are incorporated in the front braking system, whilst at the rear, high-centre-lift shoes are employed with external hydraulic operating cylinders. To improve cooling, 15f in.-diameter drums are used at the rear, where twin tyres are fitted.

Cold-squeeze rivets attach the cross-members to the frame and an L-section reinforcement plate is placed between the axles at the point of maximum stress_ Channel-section cross-members are employed, but the A-bracing behind the gearbox, formerly used in Dodge vehicles, is replaced by an additional cross-member

immediately behind the cab. The front cross-member is bolted to facilitate removal when changing the engine.

The longitudinals are level on the top flanges from the rear to the cab, but are sloped down at the front and extended beyond the spring brackets to enable the bumper bar to be rigidly attached.

The standard Dodge all-metal cab is adapted to the 7-tonner, a slight modification being required to the engine cowl to accommodate the larger engine. The complete cab, together with the wings, bonnet and radiator, is carried on a sub-frame, which is flexibly mounted on the chassis. A six-point mounting, employing engine-type rubber-bonded bobbins in which there is no metallic contact, is used, these units being arranged in pairs below the front, centre and rear of the cab understructure.

On tests large concrete blocks amounting to just over 7 tons were carried as payload and the distribution of weight indicated that almost 31 per cent, of the gross load was supported on the front axle. The Dodge front axle and steering gear are planned for a heavier load, assuming that the distribution of weight might at times be more forward.

While warming up, the lorry was driven from Kew to Harrow, where it exceeded my expectations by climbing the hilt from Sudbury in third gear. It was evident on this short journey that the performance would be lively, because, using the gearbox and engine to obtain rapid acceleration, gear changes were made from third to fourth at 19 m.p.h. and top gear was engaged at 28 m.p.h. The Dodge appeared to be equal in acceleration to roost 5-tonners, and was swifter off the mark than the larger-engincd maximum-load twoaxled lorries carrying less payload.

After passing Harrow School, there is a 1 in 9 gradient which is generally prohibited to commercial vehicles. This was the next objective, and the Dodge scored points by climbing the hill on part-throttle with second gear engaged. West Hill, Harrow, which is another steep gradient, was then tackled, it includes a short in 54 section near the brow, but it was an easy secondgear climb. Low gear was used only once in 90 miles of road work and that was when making a repeat climb of West Hill with a stop-start test on the I in 51 gradient.

The hand brake held the vehicle stationary on the gradient when selecting low gear. After 20 min. of almost continuous hill-climbing, the water and oil temperatures were only 148' F. and 104' F. respectively, so that the cooling was clearly adequate. The day temperature was 54° F., but there was a stiff breeze at times.

I drove to Cranford for consumption tests over a fairly level course, which would be comparable to operation in the flat counties in Britain, or in the Low Countriec. To obtain a reasonable average of fuel consumption, I conducted identical tests with two drivers, the first being more concerned with speed, regardless ot economy, and the other keeping a more diligent eye on the .fuel-consumption rate.

During the first trial over a 9.3-mile triangular course, there were three stops at traffic lights, followed by fullthrottle acceleration to reach the normal cruising speed of 30 m.p.h. Overtaking other traffic also made exceptional inroads into the fuel supply. At the end of the course the fuel remaining was carefully measured. Ignoring a -fraction of an ounce left in the measuring jar, five pints of fuel were used, which corresponded to a consumption rate of 14.88 m.p.g. at 27.9 m.p.h. average running speed.

Tfiere was one stop in the ensuing test over the same course, and at other times the driver religiously main• tained 28-30 m.p.h. and kept behind other vehicles on the route. I would have expected a greater difference in consumption and average speed in comparison with the first test, but only f pint less fuel was used and the average speed worked out to 27.2 m.p.h. The consumption rate corresponded to 15.66 m.p.g., giving a mean of 15.2 m.p.g. for the two tests.

To make the consumption trials more comprehensive, I staged a further test between Egham and Bagshot. The route includes some undulating ground and the medium and heavy-class chassis normally have to make fairly extensive use of the intermediate gears. The Dodge was driven in the usual trunk-haulage style, maintaining 30-35 m.p.h. wherever possible, with the throttle wide open on hills.

The long drag past Virginia Water towards Sunningdale was taken in good style, using fourth gear for 14 min., and on other gradients, 5-tonners using an indirect ratio were overtaken by the Dodge in top gear. The excellent pulling characteristics of the oil engine, coupled with the liveliness of the chassis as a whole, indicate that the Dodge could work alongside any contemporary 5-tonner or 7-tonner weighing under 3 tons unladen.

Outstanding Economy Over out-and-return runs, a fuel return of 14.725 m.p.g. was obtained at 26.3 m.p.h. average speed. This is an excellent result for a 7-tonner, especially as full load was carried for the entire distance. In general service, the operator usually obtains 2-3 m.p.g. more than I secure, because of light or unladen running.

Acceleration tests verified my observation that the Dodge was quick off the mark. Using the highest four gears, it reached 20 m.p.h. from rest in 16.6 sec. and the 30 m.p.h. mark was passed in 38.2 sec. Top-gear acceleration from 10-30 m.p.h. was accompanied in early stages by torsional oscillation, but with the general high performance of the vehicle, it is unlikely that any driver would attempt to use full throttle at 10 m.p.h. in top gear. The acceleration rate in direct drive was reasonable, 20 m.p.h. being reached in 16.7 sec. and 30 m.p.h. in 41.4 sec.

In a fair amount of hill-climbing and traffic driving during the previous tests, I had ample opportunity of studying the steering, which was easy, and the efficiency of braking. The brakes were particularly effective in normal traffic work. When conducting the braking trials, using about 200 lb. pedal pressure, the rear wheels locked for up to 30 ft. from 30 m.p.h. on a close-grained concrete road. Stopping distances ranged up to 81 ft. from this speed and 31-34 ft. when braking from 20 m.p.h.

Stopped in 64 ft. from 30 m.p.h.

A better surface of clean and fairly coarse concrete was found nearby and further tests were conducted with progressive pedal pressure. Measured with a solenoidoperated pistol, which marks the point where initial pressure is applied on the pedal, the Dodge was stopped in 64 ft. front 30 m.p.h. and 31 ft. from 20 m.p.h. These readings are fairly accurate records of the maximum braking efficiency with a normal pedal pressure.

Readings of the temperatures taken at the end of the day's trials showed the Dodge to be adequately cooled, the top-tank temperature registering 128° F. and engine oil 120° F. I returned the vehicle to Kew, feeling that it will meet with the approval of operators for its low price and economy. Drivers will appreciate the cool and comfortable cab, with its light controls, and the performdrice will be a sales asset.