ROADSIDE AND GARAGE.•

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

Interesting Contributions from Our Driver and Mechanic Readers.

A Chain-coupling Tool.

MHE driver of a chain-driven lorry;

"E.H." of Walsall, tells us that he often has one of the chains break ; so frequent is this occurrence that he appears to have made a special tool for bringing the ends of his chain together so that he can insert a coupling bolt.

The tool which he suggests could be made from a piece of gas barrel to which is brazed or welded one of the hooks which engage the links of the chain. Inside this part slides a long bolt, with a hook attached by brazing or welding. The nut of the bolt can be used to draw the hooks together and so tighten the chain.

The tool would undoubtedly be a very useful one for putting a chain on to its sprockets, but we would hardly have thought that if all was in order it would be necessary for a driver to carry such a tool with him. Chains usually break through being too slack and mounting the teeth of the sprockets. Another cause is running them until they are hopelessly out of pitch with the sprockets through wear. in the links. A fruitful cause of breakage is neglect of proper means for securing the coupling bolt, which often works out of one of the links, thus throwing all the strain on one link, which soon gives way.

"EH." appears to look upon the spanner which is used for adjusting the radius rod as a garage tool and does not carry it with him. Probably this is the cause of the frequent trouble with his chains. Good chains kept in Proper adjustment should not break unless some unforeseen accident occurs.

Reassembling Ball-thrust Bearings.

A WMINING is given by "E.W.Y.,"

of Cardiff, to those who are responsible for the reassembly of parts where ball-thrust bearings are employed, as he has apparently seen some instances of damage done by the wrong assembly of such parts. He writes :— "Too much importance cannot be attached to the reed for care in fitting double thrusts on such parts as rearaxle worm shafts, gearbox main shafts, steering columns, etc. Although designs vary in detail, the purpose of the thrust is important and constant, and the object of the fitting can easily he rendered useless by overlooking any one of its component parts. Thus very often a journal bearing or nut and washer, or other parts not designed to take thrust, are made to de so, and ultimately parts of a costly, nature require renewal in consequence.

"Firstly, all parts of a rear diameter to the shaft rely on the end nut for being clamped up solid with the shaft, so that it is imperative that the nut be fixed dead tight. The parts so clamped include a distance piece (or two halfdistance pieces), the length of which is a very important factor; and if only few thousandths too short would clamp up the races and washers. Care must be taken to see that the distance piece is sufficiently longer than the combined thicknesses of the thrust washers and races in order to allow freedom of the balls round their races, but no lateral play.

Assuming in the design that the centre washer is clamped on to the shaft between two distance pieces, then the two outer washers must be contained without lateral movement in the housing casting, which usually bolts' on to the main casting. One of these will take the forward and the other the backward thrust.

"Another design provides for the centre washer to be held rigidly in the housing and the two outer washers to rotate with the shaft.

"In either case, the greatest care should be taken that the halls have just that amount of freedom which prevents binding, but no more"

Curing. a Slipping Belt.

MUCH trouble through boiling often

results from a slipping fan belt, and serious damage to engines has occurred from 'overheating, the cause of •which could not be discovered so long as the radiator or the water circulation was suspected of being the sole cause of the trouble. As a last resource we have known the fan belt to be made to drive more efficiently, and the trouble stopped immediately.

It is possible for a fan to appear to he driving at its notmal speed, although half the speed of the belt is lost in slip A correspondent, "AS.," of Pontypridd, tells us how he overcame a slipping fan belt without unduly tightening the belt, which of course tends to shorten its life and puts much strain on the spindle bearing. His plan is to procure some ordinary tubber bands from a stationer's' shop and put them side by side on the part of the pulley where the belt rests. This not only increases the coefficient of friction, but it slightly increases the diameter of the pulley. The bands he used were In. wide. Care should be taken that no grease or oil gets to the bands.

A Valve Tip.

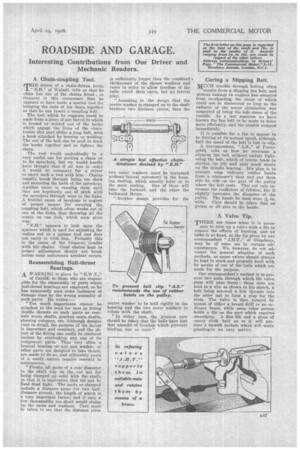

THERE are times when it is neces sary to trim up a valve with a file to remove the effects of burning, and no lathe is at hand, so-the tip given by our correspondent " J.H.T.," of GlitzeburY, may be of some use in certain circumstances. We, however, do not advocate the general adoption of such methods, as spare valves should always be kept in stock and properly dealt with by means of one of the tools which are made for the purpose.

Our correspondent's method is to procure two nuts, through which the valve stem will pass freely ; these nuts are held in a vice as shown in his sketch, a bolt being screwed a few threads into the outer nut to form a stop for the stein. The valve is then rotated by means of either a breast drill or an ordinary brace, while some other person holds a file on the part which requires smoothing. A fine file and a piece of emery cloth held on to it will produce a smooth surface which will make grinding-in an easy matter.