A TEST OF AN UNUSUAL DIFFERENTIAL

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

A Type of Device which has Engaged the Attention of Inventors for Many Years.

r1114E De Lavaud free-wheel differen tial is now being introduced into this country after having undergone severe tests in France. The following advantages over the usual form of differential gear are claimed :--(1) The provision of a free-wheel at the dictation of the driver and in either direction, thus reducing the difficulty of changing gears, (2) economy of petrol consumption, (3) reduced tendency to skid and (4) the elimination of wheelspin.

At a demonstration we witnessed. of the device at Brooklands on Wednesday last we were shown a car fitted with an ordinary differential gear, which was Placed on the beginning of a steep incline. A greasy board was placed under one of the rear wheels and the clutch was let in gently. No effort an the part of the driver could induce the car to move, as, although the wheel that rested on the ordinary road was adhering well, the tyre that was on the greasy board was slipping, the wheel revolving without imparting motion to the car.

Another car, fitted with the De Lavaud device, was then placed in exactly the same position, but because of the ratchet-like drive of both wheels the car moved forward, the wheel which rested on the ordinary road transmitting all the drive of the engine to that wheel, the other wheel being inert.

Other demonstrations were given in which attempts to produce a skid on a dry road only resulted in the car automatically finding a straight course owing to the nature of the drive, which always tends to transmit the power evenly to both wheels.

The effect of the device is that of driving both rear axles with ratchets, so that while running in a straight line the vehicle shall be driven evenly by both rear wheels, but, on turning a corner, the inner wheel only will drive, the outer one overrunning by means of the ratchet action. We are not sure that an action of this kind will enable a heavy lorry to turn a sharp corner, but we will, however, reserve our opinion on this point until we have tried the device on something heavier than a private car.

It is already known that a ratchet drive will prevent wheelspin and wobble of the front wheels. We merely use the word " ratchet " to describe the unidirectional drive, although no ratchets with teeth and pawl are used in the present case.

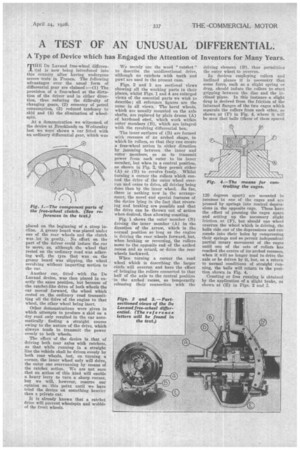

Figs. 2 and 3 are sectional views showing all the working parts in their places, whilst Figs. 1 and 4 are enlarged views of the essential parts we wish to describe; all reference figures are the same in all views. The bevel wheels. which are usually mounted on the axle shafts, are replaced by plain drums (A) of hardened steel, which work within outer members (B), which are integral with the revolving differential box.

The inner surfaces of (B) are formed with recesses of an arched shape, in which lie rollers, so that they can create a free-wheel action in either direction by jamming between the inner and outer members, so as to transmit power from each outer to its inner member, but when in a central position, as shown in Fig. 2, they permit either (A) or (B) to revolve freely. Whilst turning a corner the rollers which control the drive of the outer wheel overrun and cease to drive, all driving being done then by the inner wheel. So far, there is nothing new in the arrangement, the novel and special features of the device lying in the fact that reversing and braking are possible and that the drive can be thrown out of action when desired, thus allowing coasting.

Fig. 1 shows the outer member (B) driving the inner member (A) in the direction of the arrow, which is the normal position so long as the engine is driving the rear wheels forward, but, when braking or reversing, the rollers move to the opposite end of the arched recess and so retard, or drive the rear wheels backward.

When turning a corner the road wheel which is describing the larger circle will overrun and have the effect of bringing the rollers connected to that half of the axle to the central position in the arched recess, so temporarily releasing their connection with the driving element (B), thus permitting the outer wheel to overrun.

In devices employing rollers and inclined planes it is necessary that some force, such as a slight spring or drag, should induce the rollers to start gripping between the disc and the inclined plane. In this instance a slight drag is derived from the friction of the inturned flanges of the two cages which separate the rollers from each other, as shown at (I') in Fig. 4, where it will be seen that balls (three of them spaced

120 degrees apart) are mounted in recesses in one of the cages and are Pressed by springs into conical depressions in the opposite cage. These have the effect of pressing the cages apart and setting up the necessary slight friction at (F), but should one wheel overrun the wheel which is driving, the balls ride out of the depressions and can recede into their holes by compressing their springs and so permit independent partial rotary movement of the cages until one of the sets of rollers has reached the centre of its arched recesses, when it will no longer tend to drive the axle or be driven by it, but, on a return to normal conditions of straight running, the balls will return to the position shown in Fig. 4.

Coasting or free running is obtained by the application of a slight brake, as shown at (E) in Figs. 2 and 3.