GOING for G EEN

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

Truck engine designers have cleaned up their act to meet the Euro-1 emission limit. But Euro-2 is on the way, and there's murmurings of Euro-3. No wonder there's so much talk of cats and traps...

Unless you have spent the past couple of years on a desert island you must be aware of the new emission regulations. Euro-1 came into effect last October for vehicles being type approved and covers those being registered from I October this year. But even before it comes into force the DOT put out a consultation paper about avoiding the limits with a derogation. In the event the manufacturers' R&D teams seem to have taken Eum-1 in their stride—but Euro-2 is on the way.

Some engine manufacturers claim to be able to meet Euro-2 in the lab, but they want to beat the limits by about 15% to allow for variations in engines coming off the line. Daf has stolen a march by launching Euro-2 engines two years ahead of the deadline (CM 16-22 Sept).

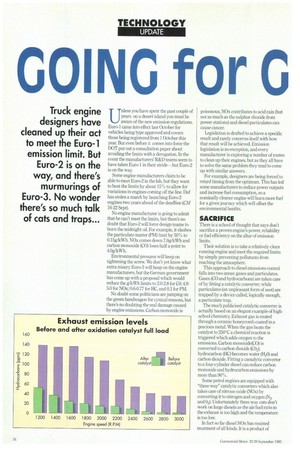

No engine manufacturer is going to admit that he can't meet the limits, but there's no doubt that Euro-2 will force design teams to burn the midnight oil. For example, it slashes the particulate matter (PM) limit by 50% to 0,15g/kWh. NOx comes down 7.0g/kWh and carbon monoxide (CO) loses half a point to 4.0g/kWh.

Environmental presures will keep on tightening the screw. We don't yet know what extra misery Euro-3 will heap on the engine manufacturers, but the German government has come up with a proposal which would reduce the g/kWh limits to 2.0-2.8 for CO; 4.95.0 for NOx; 0.6-0.77 for HC, and 0.1 for PM.

No doubt some politicians are jumping on the green bandwagon for cynical reasons, but there's no doubting the real damage caused by engine emissions. Carbon monoxide is poisonous, NOx contributes to acid rain (but not as much as the sulphur dioxide from power stations) and diesel particulates can cause cancer.

Legislation is drafted to achieve a specific result and rarely concerns itself with how that result will be achieved. Emission legislation is no exception, and every manufacturer is exploring a number of routes to clean up their engines, but as they all have to solve the same problem they tend to come up with similar answers.

For example, designers are being forced to retard timing from the optimum. This has led some manufacturers to reduce power outputs and increase fuel consumption, so a nominally cleaner engine will burn more fuel for a given journey which will offset the environmental benfits.

SACRIFICE

There is a school of thought that says don't sacrifice a proven engine's power, reliability or fuel efficiency on the altar of emission limits.

Their solution is to take a relatively clean running engine and meet the required limits by simply preventing pollutants from reaching the atmosphere.

This approach to diesel emissions control falls into two areas: gases and particulates. Gases (CO and hydrocarbons) are taken care of by fitting a catalytic converter; while particulates (an unpleasant form of soot) are trapped by a device called, logically enough, a particulate trap.

The much publicised catalytic converter is actually based on an elegant example of highschool chemistry. Exhaust gas is routed through a ceramic honeycomb coated in a precious metal. When the gas heats the catalyst to 250°C a chemical reaction is triggered which adds oxygen to the emissions. Carbon monoxide(CO) is converted to carbon dioxide (CO2); hydrocarbon (HC) becomes water (H20) and carbon dioxide. Fitting a castalytic converter to a four-cylinder diesel can reduce carbon monoxide and hydrocarbon emissions by more than 90%.

Some petrol engines are equipped with "three-way" catalytic converters which also takes care of nitrous oxide (NOx) by converting it to nitrogen and oxygen (N2 and 02). Unfortunately three way cats don't work on large diesels as the air/fuel ratio in the exhaust is too high and the temperature is too low.

In fact so far diesel NOx has resisted treatment of all kinds. It is a product of temperature and pressure in the combustion chamber —the higher the heat, the more NOx you get. This has led designers to experiment with lower compression ratios, and it has also helped kill off ceramics in engines (which is prime example of well-meaning legislation having unforseen and possibly unfortunate results).

As a further reminder that, even in

emission controls, there's no such thing as a free lunch, converting carbon monoxide to carbon dioxide furthers global warming because CO2 is a greenhouse gas.

Particulates are lumps of carbon soot covered in sulphuric acid, hydrocarbons and a number of the other unsavoury by-products of combustion. Unlike gases, particulates cannot be processed on their way through the exhaust pipe. Instead they are caught and burnt by using a wall flow filter.

Once again a honeycomb lies at the heart of the process, but each passage has one end blocked off. Exhaust gas enters the open end of one passage, passes through the wall and exits from the open end of the next passage. Erninox says that its trap removes about 80% of particulates from the exhaust. After the particulates in the trap have built up to a predetermined level diesel is injected to burn them off, leaving the trap "regenerated" and ready for further use.

CONFUSION

One area where there is still some confusion in legislation is how many, if any regenerations should be included in the emission test. The Californians have, as usual, declared DI; the rest of the world is still arguing.

To burn off the particulates the injected diesel has to ignite, but because the

particulate trap works at relatively low temperatures this will not haprSen spontaneously. One way to overcome this is to combine a particulate trap with a catalytic converter, and Eminox has developed such a device for the eco-friendly Royal Mail 95 Series (tested in CM 4-10 March).

This hybrid—formally known as an automatically regenerating trap particulate filter—comprises a wall flow filter

sandwiched between two oxidation catalysts. All the exhaust passes through the first catalytic converter, which oxidises the gases, while the particulates are subsequently caught by the wall flow filter. To regenerate the trap diesel is injected onto the first catalyst, which is hot enough to ignite it and burn off the particulates in the trap. The second catalyst then cleans up any noxious PI'

11 gases produced in this process.

According to Eminox this computer controlled combination slashes CO, HC and particulate emissions, leaving only NOx relatively unaffected. This technology doesn't come cheap—production models are expected to cost around £6,000—but there has been a premium of around £1,000 for updating some existing engines to meet Euro-1, and meeting Euro-2 has pushed up the price of Daf's 11.6-litre unit by another £2,000.

Engine manufacturers do have other cards to play in the emissions game. Some are banking on multi-valve heads, or multi-hole injectors; others are putting their money on electronically controlled diesel pumps (EDC) or electronic unit injectors.

Using more valves in the head and more holes in the injectors improves fuel/air mixing, leading to more complete combustion and lower emissions.

SECRET

It's no secret that injecting the exactly the right amount of fuel at exactly the right time will keep emissions to a minimum, but converting theory to practice has not been easy.Traditionally, the required advance and timing curves for mechanical fuel pumps are determined by running a number of tests over the load/speed range with a series of different static pump timings. The best average is then used on production engines.

Electronic diesel control (EDC) is the first step to computerisation. It incorporates a drive-by-wire system which electronically moderates the rack position on a mechanical pump. A simple engine monitoring system can reduce the amount of diesel being injected to avoid, or at least reduce, over fuelling.

The Achilles heel on both mechanical and EDC systems is the ever increasing pressures in the injection pipes. To reduce emissions the fuel has to be injected more quickly through smaller holes improve mixing and to allow time for more complete combustion. Injection pressures have risen to 1,200bar, which is causing the pipes to bulge as the fuel surges through.

DEFEATS

This not only defeats the object of raising the injection pressures but can also cause problems such as secondary injections. Nonetheless Peter de Kok, Daf's head of engine development, predicts pressures up to 1,800bar when Euro-3 is introduced.

Many manufacturers are looking at electronically controlled unit injectors to deliver these pressures, using an overheadcam or pushrod system of actuation. Volvo's latest 12litre Euro-1 engine uses Lucas OHC unit injectors to deliver fuel at up to 1,500bar.

As well as delivering fuel at much higher pressures, these systems also allow the fuelling for each injector to be individually set, with the timing controlled by a solenoid. By computer mapping the engine, fueling and timing can be continually adjusted to the optimum throughout the load/speed range.

Daf's R&D team has managed to meet Euro-2 without using electronics, cats or traps—but no doubt the green lobby groups will now tell Euro politicians: "It would be even cleaner and greener if a cat were bolted on." So despite the best efforts of the engine manufacturers, after treatment devices could become the norm on heavies.

CALCULATED

It has been calculated that under present levels of technology, only three parts in 1,000 of diesel exhaust are noxious. To reduce this level further will cost millions of pounds, and the legislation will only apply to new vehicles. It is likely that more stringent inservice testing will be introduced to catch older vehicles (and the odd vote).

But road-going vehicles only use about 43% of the UK's diesel (with cars accounting for over 6% and rising). Most is used in domestic and industrial heating systems, generators. marine and industrial engines, plant and trains—and these are governed by less stringent emission limits, or by none at all. Then there are the power stations, which are far an away the biggest contributors to acid rain.

Truck engine manufacturers have strong grounds for demanding that other users should have to clean up their act to the Euro-1 equivalent before road transport has to spend many millions more to meet Euro-3 and beyond.

After all, we all share the same environment.

0 by Colin Sowman