Future trends in transmissions

Page 164

Page 165

Page 166

Page 167

Page 168

Page 170

Page 171

If you've noticed an error in this article please click here to report it so we can fix it.

BY D. THAW, AMIMechE, AMIMarE

technical director, Eaton ENV Transmissions Ltd.

■ TY prudent author of a Paper attempting to see into the future should outline some of the factors which will [ence transmission trends. These include: future national sport policy; future national highway programmes; future Dnal vehicle regulations; future taxation policy; future s of prime mover. In addition to the above, our status as gh volume exporter of motor vehicles involves us in the lations of many other countries.

'ith so many imponderables it is wise to begin our review the immediate future and to proceed to the medium and long term in the realization that the further we ince into the future the more unreliable our predictions line. Although there is scope for ingenuity on the part of transmission designer, the basic transmission specification t for him by others. He is the servant of the truck manuirer, who in turn has to produce a vehicle attractive to :ustomers in specification, performance and price.

immediate futu re le conventional stepped-ratio truck transmission has hed a high state of development and is simple, efficient economical. It is capable of being further developed to : such changes in vehicle operation as can be envisaged le immediate future. The adoption of synchromesh is eeding slowly; but it is to be expected that all transmis; suitable for engines of up to 500 lb. ft. torque capacity eventually be of this type. At this point the inertia of the ; to be synchronized will tax the conventional synnizing mechanism and the more powerful types, such as developed by Smiths and shown in Fig. 1, will probably tecessary.

current problem is that, in the short term at least, some ;le categories are suffering a decline in power to weight . The changes in the Construction and Use Regulations ,64 allow the operation of tractor-trailer units up to 32 tons

Until the demand for high-power engines increases their production to the point where their price vehicle manufacturers are compelled to equip with available but under-powered engines. I power to weight ratios are as low as 5.5 b.h.p. leads to sluggish performance and poor grade gear, this in turn leading to higher usage of till gear ratios.

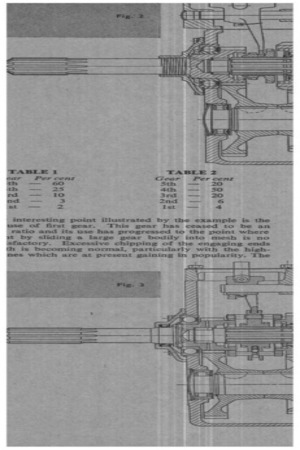

Normal rigid truck transmission is predicated t use of the top gear in which the input shaft( directly together and no power is circulated thr( ing. Table 1, over page, is a prediction of perce running time spent in each gear of a five-speed ti these circumstances. As an illustration, if the g the truck is such that only 20 per cent of the tinni in top gear Table 2 shows the resulting redistrib It will be seen that the duties of the intermedia doubled and their life correspondingly shorten( time as vehicles are equipped with engines giN weight ratio of 6.5 b.h.p. per ton or more, sor transmissions than those indicated by engine tor( be necessary. interesting point illustrated by the example is the use a first gear. This gear has ceased to be an ratio and its use has progressed to the point where it by sliding a large gear bodily into mesh is no sfactory. Excessive chipping of the engaging ends th is becoming normal, particularly with the highnes which are at present gaining in popularity. The

steps is then chosen to allow the engine to work within a cp.' narrow speed range giving the best balance of performs' and economy whatever the terrain the vehicle traverses. W only few ratios there will be large engine speed variatii With more ratios these variations will be smaller. Figs. 4 a 5 illustrate the principle.

In the vehicle range up to 16 tons g.v.w. and 24 tons g.c the 10-speed transmission is well established and likely remain so. Above these operating weights the use of and 15-speed transmissions is likely to gain in popularity. both cases alternative solutions are available where eitl all ratios are in the gearbox or a simpler gearbox is used w a multi-speed axle.

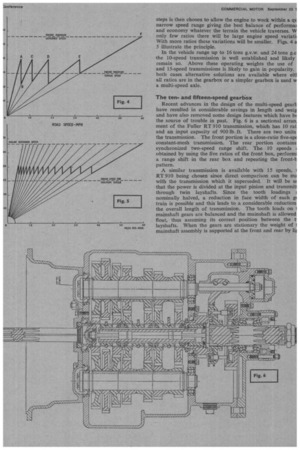

The tenand fifteen-speed gearbox Recent advances in the design of the multi-speed gearb have resulted in considerable savings in length and weig and have also removed some design features which have Ix the source of trouble in past. Fig. 6 is a sectional arran; rnent of the Fuller RT 910 transmission, which has 10 rat and an input capacity of 900 lb. ft. There are two units the transmission. The front portion is a close-ratio five-spc constant-mesh transmission. The rear portion contains synchronized two-speed range shift. The 10 speeds ; obtained by using the five ratios of the front box, performi a range shift in the rear box and repeating the front-b pattern.

A similar transmission is available with 15 speeds, 1 RT 910 being chosen since direct comparison can be ma with the transmission which it superseded. It will be sc that the power is divided at the input pinion and transmiti through twin layshafts. Since the tooth loadings ; nominally halved, a reduction in face width of each gt train is possible and this leads to a considerable reduction the overall length of transmission. The tooth loads on 1 mainshaft gears are balanced and the mainshaft is allowed float, thus assuming its correct position between the t layshafts. When the gears are stationary the weight of mainshaft assembly is supported at the front and rear by 14 since there is no resultant tooth load on the mainirs, no load-carrying bearings between these and the are necessary, nor does the spigot bearing between ishaft and primary shaft play a major part in gear .T 910 replaced a similar single-layshaft gearbox and wing table shows the advantages of the twin-layshaft Jetion in length. of 101 in. is particularly valuable in t-wheelbase tractor unit, where it eases the problem Iler shaft angles.

r designs for multi-speed range shift transmissions !ri developed in Sweden by Volvo and Scania Vabis, :etain the single-layshaft principle but which, in to having a synchronized range shift, have also a chronized front gearbox. In Germany, too, the cornof a fiveor six-speed synchronized transmission and .onized splitter gearbox is being investigated.

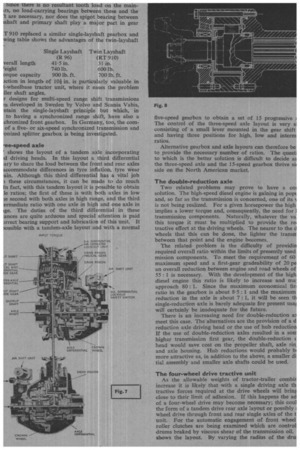

.ee-speed axle ' shows the layout of a tandem axle incorporating A driving heads. In this layout a third differential ary to share the load between the front and rear axles accommodate differences in tyre inflation, tyre Wear airs. Although this third differential has a vital job .1 these circumstances, it can be made to do much In fact, with this tandem layout it is possible to obtain le ratios; the first of these is with both axles in low le second with both axles in high range, and the third ermediate ratio with one axle in high and one axle in [ge. The duties of the third differential in these .ances are quite arduous and special attention is paid meet bearing support and lubrication of this unit. It aossible with a tandem-axle layout and with a normal five-speed gearbox to obtain a set of 15 progressive 1 The control of the three-speed axle layout is very si consisting of a small lever mounted in the gear shift and having three positions for high, low and interm ratios.

Alternative gearbox and axle layouts can therefore be to provide the necessary number of ratios. The questi to which is the better solution is difficult to decide as the three-speed axle and the 15-speed gearbox thrive 511 side on the North American market.

The double-reduction axle

Two related problems may prove to have a CO3 solution, The high-speed diesel engine is gaining in pops and, so far as the transmission is concerned, one of its s is not being realized. For a given horsepower the high implies a lower torque and, consequently, the need for transmission components. Naturally, whatever the va: this torque it must be multiplied to provide the re, tractive effort at the driving wheels. The nearer to the d Wheels that this can be done, the lighter the transrr between that point and the engine becomes.

The related problem is the difficulty of providin required overall ratio within the limits of presently used mission components. To meet the requirement of 60 maximum speed and a first-gear gradeability of 20 pe an overall reduction between engine and road wheels of 55: I is necessary. With the development of the high diesel engine this ratio is likely to increase and ma: approach 80: 1. Since the maximum economical fin ratio in the gearbox is about 85: 1 and the maximum reduction in the axle is about 7 : 1, it will be seen th single-reduction axle is barely adequate for present usa4 will certainly be inadequate for the future.

There is an increasing need for double-reduction a, meet this case. The alternatives are the provision of a d reduction axle driving head or the use of hub reduction If the use of double-reduction axles resulted in a som higher transmission first gear, the double-reduction head would save cost on the propeller shaft, axle rin, and axle housing. Hub reductions would probably IN more attractive as, in addition to the above, a smaller di tial assembly and smaller axle shafts could be used.

The four-wheel drive tractive unit As the allowable weights of tractor-trailer combir increase it is likely that with a single driving axle th tractive forces required at the drive wheels will bring close to their limit of adhesion. If this happens the ad of a four-wheel drive may become necessary; this coal the form of a tandem drive rear axle layout or possibly wheel drive through front and rear single axles of the t unit. For the automatic engagement of front wheel roller clutches are being examined which are control drums braked by viscous shear of the transmission oil. shows the layout. By varying the radius of the dru: thickness of the oil annulus to be sheared, the speed Tence between front and rear wheels at which the clutch anatically engages can be closely controlled.

1 medium term may well be that the most profound influence on transions in the medium term will be in the field of engine :lopment. If the operator is embarrassed by the number atios required to give his truck performance with economy, if automatic transmissions are held back because of their efficiency, the real culprit is the reciprocating internal bustion engine. Its torque curve is unsuited for the autoive application and the proliferation of ratios is a direct ;equence. Its efficiency in terms of heat input and hanical work output puts the efficiency of the automatic smission in a very favourable light. Fig. 9 shows as full ; a typical engine torque curve and the tractive effort tired at the drive wheels of a truck. I realize that this aposition of curves can be subject to many objections. se do not read more into it than the comparison of the m of two curves. Nevertheless the difference between t is offered and what is required is startling.

ig. 10 shows the tractive effort available in each ratio of a speed gearbox. It will be seen that there are gaps between lable tractive efforts in each ratio. Conditions occurring in e gaps necessitate a down-change to a ratio which has ter torque potential. The fact that the full potential of lower gear is not utilized means that the engine is forced on in an uneconomical speed range. Naturally the more )s used in the transmission the fewer the tractive effort ; and the more likelihood of having a ratio for any condiwhilst running the engine at an economical speed. If, ever, the horsepower and torque characteristics of the ne could be drastically altered the transmission would be ffified almost to the point of its disappearance.

xperimental attempts have been made in the USA to ilify the transmission by the use of larger engines. This the effect of increasing the tractive effort available in each ) and a five-speed gearbox with a single-speed axle has red practicable with g.c.vv.'s of 60,000 lb.

more fundamental approach has been made by Perkins in this country, with their differentially supercharged ne. The engine drives a differential gear, the two outputs 3 this device driving the transmission and an engine superIgen When the vehicle meets with resistance, as in climbs grade, the output from the differential (i.e. that connected to the transmission) slows down. This has the ei ing the speed of the other output which drives ti faster which in turn produces more engine hors and tractive effort at the road wheels. This engine power output with vehicle power req continuing process. This engine requires on] gearbox and it will be seen from Fig. 11 tha tractive effort is very close to the ideal.

Another interesting development was outfit to the Institution of Mechanical Engineers by ; In this a variable speed drive from the engine the supercharger to supply a constant volumt engine whatever the crankshaft speed. In ot the maximum combustion pressures an ingeni varying the compression ratio has been devise, been reproduced from the paper and shows tl flat b.h.p. curve and the falling torque curve matches the curve of desirable tractive effort.

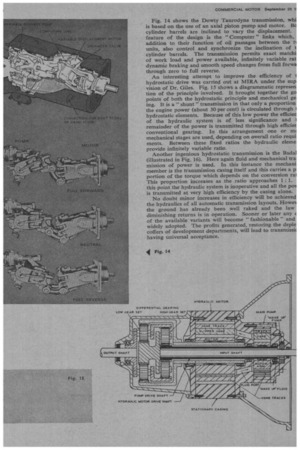

Bridging the gap It will have been noticed in the discourse o number of ratios that the greater the numbe more efficiently can the engine be operated. leads to the thought that the automatic trans be ideal since within its total range it has avail number of ratios. This, however, is not the ord since economics enter the picture as well as fitnt We need only say at this point that the efficien matic transmission is not yet quite acceptabl■ operator will look very carefully at the extra in big costs and weigh them against his requireme There seems to be a need for some bridgi between the present manual transmission and transmission. This could well take the form interest in the epicyclic transmission coupled through a hydraulic coupling. This would g the gear changing operation and give a "hot teristic which is useful in keeping the vehicle ro: circumstances. It makes for easy starting fro: clutch operation. It also avoids a feeling on driver that the transmission is no longer und as is the case with automatics. Since some of to the introduction of even synchronized gearl professional pride on the part of the drivers sideration is a very real one. The type 0 Fig. 14 shows the Dowty Taurodyne transmission, whi is based on the use of an axial piston pump and motor. Be cylinder barrels are inclined to vary the displacement. feature of the design is the " Computer " links which, addition to their function of oil passages between the t% units, also control and synchronize the inclination of t cylinder barrels. The transmission permits exact matchi of work load and power available, infinitely variable rat dynamic braking and smooth speed changes from full forwa through zero to full reverse.

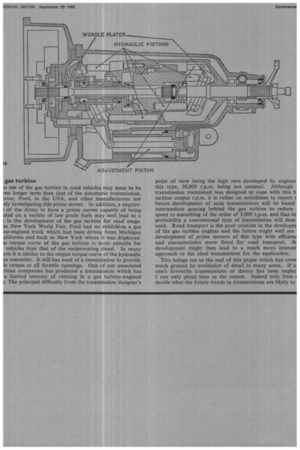

An interesting attempt to improve the efficiency of t hydrostatic drive was carried out at MIRA under the sup, vision of Dr. Giles. Fig. 15 shows a diagrammatic represen tion of the principle involved. It brought together the go points of both the hydrostatic principle and mechanical ge. ing. It is a " shunt " transmission in that only a proportion the engine power (about 30 per cent) is circulated through I hydrostatic elements. Because of this low power the efficien of the hydraulic system is of less significance and remainder of the power is transmitted through high efficier conventional gearing. in this arrangement one or m( mechanical stages are used, depending on overall ratio requi ments. Between these fixed ratios the hydraulic eIeme provide infinitely variable ratio.

Another ingenious hydrostatic transmission is the BadaI (illustrated in Fig. 16). Here again fluid and mechanical tra mission of power is used. In this instance the mechani member is the transmission casing itself and this carries a p portion of the torque which depends on the conversion rat This proportion increases as the ratio approaches 1 : 1. this point the hydraulic system is inoperative and all the pot is transmitted at very high efficiency by the casing alone.

No doubt minor increases in efficiency will be achieved the hydraulics of all automatic transmission layouts. Howes the ground has already been well raked and the law diminishing returns is in operation. Sooner or later any of the available variants will become " fashionable " and widely adopted. The profits generated, restoring the deple coffers of development departments, will lead to transmissic having universal acceptance.

gas turbine

te use of the gas turbine in road vehicles may seem to be 'Fen longer term than that of the automatic transmission. ,ever, Ford, in the USA, and other manufacturers are ely investigating this prime mover. In addition, a requireof the Army to have a prime mover capable of being ated on a variety of low grade fuels may well lead to a t in the development of the gas turbine for road usage. he New York World Fair, Ford had on exhibition a gas [ne-engined truck which had been driven from Michigan alifornia and back to New York where it was displayed. le torque curve of the gas turbine is more suitable for vehicles than that of the reciprocating diesel. In many ,ets it is similar to the output torque curve of the hydraulic ue converter. It still has need of a transmission to provide le torque at all throttle openings. One of our associated :dean companies has produced a transmission which has a limited amount of running in a gas turbine-engined C. The principal difficulty from the transmission designer's point of view being the high revs developed by engines this type, 30,000 r.p.m. being not unusual. Although transmission mentioned was designed to cope with this Ii turbine output r.p.m. it is rather an anticlimax to report t future development of such transmissions will be based intermediate gearing behind the gas turbine to reduce speed to something of the order of 3,000 r.p.m. and that in probability a conventional type of transmission will then used. Road transport is the poor relation in the developm of the gas turbine engines and the future might well see development of prime movers of this type with efficienc and characteristics more fitted for road transport. St development might then lead to a much more interest approach to the ideal transmission for the application.

This brings me to the end of this paper which has cove: much ground by avoidance of detail in many areas. If al one's favourite transmissions or theory has been neglec I can only plead time as the reason. Indeed only time 4 decide what the future trends in transmissions are likely to