• Foden Get 210 b.h.p.

Page 145

If you've noticed an error in this article please click here to report it so we can fix it.

from 4.09 Litres

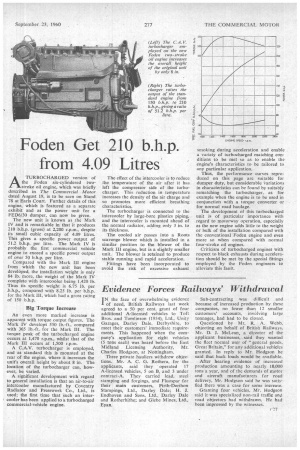

ATURBOCHARGED version of the Foden six-cylindered twostroke oil engine, which was briefly described in The Commercial Motor dated August 19, is to be seen on Stand 78 at Earls Court. Further details of this engine, which is featured as a separate exhibit and as the power unit for a FED6/30 dumper, can now be given.

The new unit is known as the Mark IV and is remarkable in that it produces 210 b.h.p. (gross) at 2,200 r.p.m., despite its small cubic capacity of 4.09 litres. This gives a specific power output of 51.2 b.h.p. per litre. The Mark IV is probably the first commercial vehicle engine to exceed a specific power output of over 50 b.h.p. per litre.

Compared with the Mark III engine from which the new unit has been developed, the installation weight is only 84 lb. more, the weight of the Mark IV complete with intercooler being 1,420 lb. Thus its specific weight is 6.75 lb. per .b.h.p., compared with 8.25 lb. per b.h.p. for the Mark 111 which had a gross rating of 150 b.h.p.

Big Torque Increase

An even more marked increase is apparent with torque output figures. The Mark IV develops 550 lb.-ft., compared with 365 lb.-ft. for the Mark HI. The torque peak of the turbocharged engine occurs at 1,470 r.p.m., whilst that of the Mark HI occurs at 1.500 r.p.m.

A C.A.V. turbocharger is employed, and as standard this is mounted at the rear of the engine, where it increases the unit's overall height by about 8 in. The location of the turbocharger can, however, be varied.

A significant development with regard to general installation is that an air-to-air intercooler manufactured by Coventry Radiator and Presswork Co., Ltd., is used; the first time that such an intercooler has been applied to a turbocharged commercial-vehicle engine. The effect of the intercooler is to reduce the temperature of the air after it has left the compressor side of the turbocharger. This reduction in temperature increases the density of the air charge and so promotes more efficient breathing characteristics.

The turbocharger is connected to the intercooler by large-bore plastics piping, and the intercooler is mounted ahead of the normal radiator, adding only 3 in. to its thickness.

The cooled air passes into a Roots scavenge blower which is installed in a similar position to the blower of the Mark III engine, but is a slightly smaller unit. The blower is retained to produce stable running and rapid acceleration.

Fittings have been incorporated to avoid the risk of excessive exhaust smoking during acceleration and enable a variety of turbocharged matching conditions to be met so as to enable the engine's Characteristics to be tailored to any particular application.

Thus, the performance curves reproduced on this page are suitable for dumper duty, but considerable Variations in characteristics can be found by suitably rematching the turbocharger, as for example when the engine is to be used in conjunction with a torque converter or for normal road haulage.

The development of this turbocharged unit is of particular importance with regard to motorway operation, especially as the new engine adds little to the weight or bulk of the installation compared with the conventional Foden engine and even more so when compared with normal four-stroke oil engines.

Criticism of turbocharged engines with respect to black exhausts during acceleration should be met by the special fittings employed by the Foden engineers to alleviate this fault.