For DRIVERS, MECHANICS & FOREMEN.

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN &LULLING S is awarded each week to the sender of the best letter which we publish on this page all others are paid for at the rate of a penny a line, with an allowance for photographs. All notes are edited before being published. Mention pour employer's name, in confidence, as evidence of good faith, Address, .D., M. and F„, "The Commercial Motor," 7-15, nosebery Avenue, London, E.C. 1.

Lamps Alight.

On Saturday, September 27th, light your lamps at 7.48 in London, 8.5 in Edinburgh, 7.57 in Newcastle, 8.1 in Liverpool, 7.58 in Birmingham, 7.58 in Bristol, and 8.14 in Dublin.

Removing Clutch Spigot Bushes.

The sender of the following communication has been

awarded the 10s. prize this week.

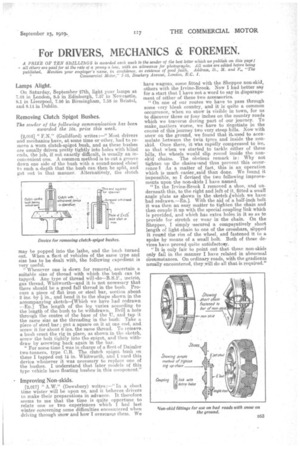

[2,016] " F.N." (Guildford) writes :—" Most drivers and mechanics have at some time or other, had to remove a worn clutch,-spigot bush, and as these bushes are usually driven pretty tightly into holes with blind ends, the job, if not exactly difficult, is usually an inconvenient one. A common method is to cut a groove down one side of the bush with a round-nosed chisel ta such a depth that the bush can then be split, and got out 'in that manner. Alternatively, the clutch

may be popped into the lathe, and the bush turned out. When a fleet of vehicles of the same type and size has to be dealt with, the following expedient is very useful. "Whenever one is down for removal, ascertain a suitable size of thread with which the bush can be tapped. Any type of thread will.do—B.S.F.,

gas thread, Whitworth—and it is not necessary that there should be a good full thread in the bush. Procure a piece of flat iron or steel bar, section about 2 ins, by in., and bend it to the shape shown in the accompanying sketch—[Which we have had redrawn —End The length of the leg varies according to the length of the bush to be withdrawn. Drill a hole through the centre of the base of the 13, and tap it the same size as the threading in the bush: Take a piece of steel bar; put a square on it at one end, and screw it for about 6 ins, the same thread. To remove a bush erect the rig in place, as shown in the sketch, screw the bolt tightly into the spigot, and 'then withdraw by screwing back again in the bar.

"For some time I was in charge of a fleet of Daimler two-tonners, type O.B. The clutch spigot bush on these I tapped out 14 in. Whitworth, and I used this device whenever it was necessary to replace one af the bushes. I understand that later models of this type vehicle have floating bushes in this component:"

• Improving Non-skids.

[2,017] " A.W." (Dewsbury) writes :—" In a short time winter will be upon us, and it behoves drivers to make their preparations in advance. It therefore seems to me that the time . is quite opportune to relate one or two experiences which. I had last winter concerning some difficulties encountered when driving through snow and how I overcame them. We have wagons, some fitted with the Sheppee non-skid, others with the Irvine-Brook. Now I had better say far a start that I have not a word to say in disparagement of either of these two areeessories.

"On one of our routes we have to pass through some very bleak country, and it is' quite a common occurrence, when no snow is visible in town, for us to discover three or four inches on the country roads which we traverse during part of our journey. To make. matters worse, we have to rfegotiate in the course of this journey two very steep hills. Now with snow on the ground, we found that it.. used to accumulate between the twin tyres and inside the nonskid. Once there, it was rapidly compressed to ice, so that when we started to tackle either of these hills, the wheels would slip round inside the nonskid chains. The obvious remark is : Why not tighten up the chainsoand thus prevent this occurrence 11 As a matter of fact, this is an operation which is much easier, said than done. We found it impossible, BO I devised the two following improvements upon the non-skids I have named.

"In the Irvine-Brook I removed a shoe, and underneath this, to the right and left of it, fitted a small angle plate as shown in the sketch fwhich we have had redrawn.—En.]. With the aid of a half-inch bolt it was then an easy matter to tighten the chain and then couple it up with the special coupling link which is provided, and which has extra holes in it so as to provide for stretch or wear in` the chain. On the Sheppee, I simply Jsectired a comparatively short length of light chain to one of the crossbars, slipped it round the rim of the wheel, and fastened it to a spoke by means of a small bolt. Both of these devices have proved quite satisfactory.

"It is only fair to point out that these non-skids only fail in the manner I have related in abnormal circumstances. On ordinary roads, with the gradients usually encountered, they will do all that is required."