Patents Completed.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Preventing Piston Ring Rotation. New Sparking Plug. An Improved Lubrication System. Steering Axle Design.

Copies of complete specifications of the patents published on this pare can be obtained from the Sales Branch, Patent Office, Holborn, W.C., at the cost of sixpence for each specification.

A. .PITTEVIT. and R. No. 17,711„ dated , 27th , M. liinxieT, No. 4434, dated 20th March, 1915.—The object

July, 1914.—The front axle is provided With'two hip in the ' of this invention is to Prevent the rotation of piston 'rings ordinary way to reenive the pivots of the stub-axle. This ii explosion engines. In the form illustrated, the piston has latter has formed in one with it vertical pivot pins turning in bearings in these lugs.

The upper bearing, which is also used as a. grease-cup, is first inserted in position and the stub-axle pivot entered into it. This is effected by letting the body of the stub-axle pass downwards through the body of the lower lug, the opening of which is made sufficiently large for that purpose. The bearing for the lower lug is then screwed in from the bottom and locked in position.

A single curved lever is fixed in the body of the stub-axle, and it is connected at one end to the steering column and at the other end to the coupling rod for the other steering wheel.

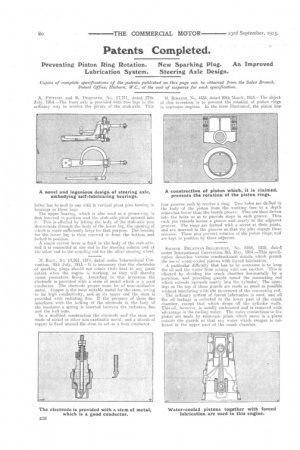

31. Rau., No. 14,561, 1914, dated under International Convention, 10th July, 1913.—It is necessary that the electrodes of sparking plugs should not retain their heat to any great extent when the engine is working, as they will thereby cause premature firing. According to this invention the electrode is provided with a stem of metal which is a good conductor. The electrode proper must be of non-oxidizable metal. Copper is the most suitable metal for the stern, owing to its high conductivity, and at its upper end the stern is provided with radiating fins. If the presence of these fins interferes with the locking of the electrode in the body of the insulator a spring is inserted between the radiating fins and the lock-nuts.

In a modified construction the electrode and the stem are made of nickel or other non-oxidizable metal, and a sheath of copper is fixed around the stem to act as a heat conductor.

four grooves each to receive a ring. Two holes are drilled in the body of the piston from the working face to a depth somewhat lower than the fourth groove. Pins are then driven into the holes so as to provide stops in each groove. Thus each pin extends across a groove and nearly to the adjacent grooves. The rings are formed with a recess at their joints, and are inserted in the grooves so that the pins engage these recesses. These pins prevent rotation of the piston rings, and are kept in position by those adjacent.

SOCIETE DELAUNAY-BELLEVILLE, NO. 6164, 1915, dated under International Convention 9th May, 1914.—This specification describes various constructional details which permit the use of water-ccoled pistons with forced lubrication.

A particular difficulty that has to be overcome is to keep the oil and the water from mixing with one another. This is effected by dividing the crank chamber horizontally by a partition, and providing guards round the connecting rod which extends upwards nearly into the cylinder. The openings at the top of these guards are made as small as possible without interfering with the movement of the connecting rod.

The ordinary system of forced lubrication is used, and all the oil leakage is collected in the lower part of the crank chamber, except that which drops off the cylinder walls. This oil, however, is usually carbonized and is removed with advantage in the cooling water. The water connections to the piston are made by telescopic joints which move in a plane outside the guards so that any water which escapes is collected in the upper part of the crank chamber.