RUNNING, UPKEEP AND OVERHAUL.

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

Interesting Contributions from Maintenance Engineers, Drivers and Mechanics.

A Useful Suggestion for Petrol-electric Vehicles.

F110M Maidstone we have received what appears to be a very useful suggestion, especially when applied to petrol-electric vehicles. Our correspondent, " W.S.M.," who has charge of petrol-electric vehicles, has at times to remove the generator and electric motor from the chassis. This he finds a difficult matter, as some of these units weigh as much as 7 cwt. apiece.

To -enable him to handle these parts when dismantling and reassembling, he has made a lifting device, a description of which he gives us, together with sketches..

A piece of stout channel-steel is cut to such a length that it will lie on the side frames. In the centre of this he mounts a gunmetal nut and a screw 2 ft. long by 31 in. in diameter. At the lower end of this screw he fixes a 1-in, thrust bearing which supports a fork as shown. The fork is placed over the ring on the top of the electric unit -and a bolt passed through, so that it can be lowered or raised by means of the screw.

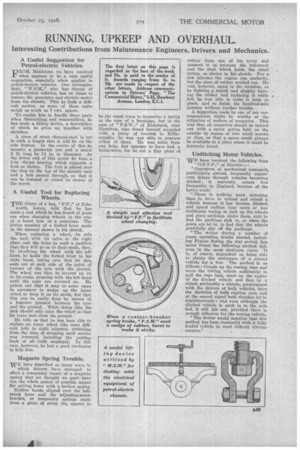

A Useful Tool for Replacing Wheels.

THE driver of a bus, " F.F.," of Fain

worth, Lanes, tells that he has made a tool which he has found of great use when changing wheels in the case of a burst tyre or a puncture. The device consists of a forked lever made in the manner shown in his sketch.

When replacing a wheel, he sets the unit with its valve in the right place and the holes in such a position that they will go on to their studs, then, by steadying the wheel with his left hand, he holds the forked lever in his right hand, taking care that its thin ends are at each side of the point of contact of the tyre with the ground. The wheel can then be levered up on to its studs, pressing with the left hand until the nuts are screwed on. He points oat that it may in some • cases be necessary to wedge up the inner wheel to keep it on its studs, hut that this can be easily done by means of a hammer jammed between the tyre and the ground. While doing this, the jack should only raise the wheel so that its tyres just clear the ground.

He tells us that he has been able to replace an inner wheel (the most difficult job) in eight minutes; reckoning from the time of stopping until service was resumed, including the putting back of all tools employed. In this ease, however, he had a good conductor to help him.

Magneto Spring Trouble.

WE have described so many ways in which drivers have managed to effect a temporary repair of a magneto, spring that we thought we must have run the whole gamut of possible means for getting home with a broken spring. Rubber bands slipped over the bellcrank lever and the adjusting-screw bracket, or temporary springs made from a piece of scrap tin, appear to

be the usual ways to improVise a spring in the ease of a breakage, but in the case of " P.S.W.," of Burnbank, near Hamilton, who found himself stranded with a party of tourists in Killieerankie, he was not able to precure either of these. He was miles from any help, but appears to have had a brain-wave, for he cut a tiny piece of rubber from one of his tyres and jammed it in between the bell-crank and the stud which holds the small spring, as shown in his sketch. For a few minutes' the engine ran perfectly, but the piece of rubber worked out. He was, however, equal to the occasion, as by lighting a match and slightly burn-. jug the rubber and replacing it while hot, he was able to make it keep in place, and to finish his hundred-mile journey without further trouble.

A suggestion made by one of our correspondents might be worthy of the attention of makers of magnetos. This was that all magnetos should be turned out with a spare spring held on the outside by means of two small screws or clips, so that a spare could always be available in a place where it could be instantly found.

Unditching Motor Vehicles.

wE have received the following from " 0.P.V.P.," of Ilendon

• " Operators of mechanical transport, particularly abroad, frequently experience delays through vehicles becoming ditched ; it naturally occurs less frequently in England, because of the better roads.

"There is nothing more annoying -than to have to unload and reload 'a vehicle because it has become ditched, and spend endless time more or less fruitlessly trying to jack up the wheels and place packings under them, only to find the packings sink in, or when the gears are let in, to find that the wheels gracefully slip off the packings.

"The writer during a number of years operating trucks abroad, including France during the war period, has never found the following method fail, even in the most obstinate cases. It is, of course, dependent on being able to obtain the assistance of a second vehicle for a tow. The method is as follows : Couple up the towing rope and move the towing vehicle sufficiently to Pull the rope taut, start up the engine of the ditched vehicle and then by a signal, preferably a whistle, prearranged with the drivers of both vehicles, have the throttles of both' engines open and at the second signal both clutches let in simultaneously ; and even although the ditched • vehicle is sunk in to the axle bed, it will lift out, provided there is enough adhesion for the towing vehicle.

"The Writer would mention that this method has been successful with a fully loaded vehicle in most difficult circumstances."