GUY'S LATEST: A LIGHT 30-CWT. CHASSIS.

Page 13

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

MITERE appears to be an increas ing demand for a light goods chassis capable of attaining comparatively high speeds and possessing the power of rapid acceleration to meet traffic conditions. At the same time, such a chassis must be efficient, easy to maintain and moderate in first cost, and_ we consider that all these qualifications are embodied in the new 30-ewt. ON model Guy.

It has a 90 min, by 130 mm. fourcylindered engine, carefully balanced and capable of running at 3,000 r.p.m., a simple, single dry-plate clutch the springs of which do not require adjustment, a four-speed gearbox built up as a unit with the

engine, and a propeller shaft with a Hardy joint at the forward end and a Spicer joint and plunger at the rear end, the final drive being by overhead worm. Both brakes operate on the rear-wheel drums, but front-wheel brakes can be fitted as an extra ; this also applies to the provision of a Dewandre servo.

The price, including a Lucas 12volt lamp set (consisting of headlights on the wings and a tail lamp), Vise() air cleaner, Lucas starter. speedometer, electric horn arid spare wheel and tyre, is 1348.

The track is 4 ft. 9J, ins., and this, together with the high power-weight ratio, excellent clearance, pumpwater circulation and efficient cool

ing, renders the chassis particularly suitable for overseas use. The engine is arranged with all the most important auxiliaries at the near side or at the front and, readily accessible, so that forward control can be provided ; as a matter of fact, the company will be producing a chassis of the forwardcon troI pattern as well as that which we are describing.

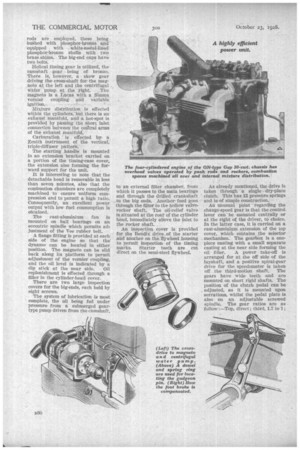

Dealing now with the details of the design and commencing with the engine, this has overhead valves operated, by push rods and rocker arms ; the rockers are steel stampjugs on bronze bushes and carry adjustable pins bearing in cups on the 'very light tubular push rods. The cylinders are cast with the upper half of the crankcase and, of course, have a detachable head in which, incidentally, the sparking plugs are inserted at an angle at the off side.

The crankshaft, which has 2i-in, journals and crankpins, Is mounted on three main bearings with four-bolt caps. The pistons are of the same grade cast-iron as the cylinders. Each has three ordinary rings and a scraper groove at the top, the piston pins are dowelled into the pistons, each being located by a wide spring-steel band.

Duralurnin connecting rods are employed, these being buShed with phosphor-bronze and 'equipped with white-metal-lined phosphor-bronze shells with two brass shims. The big-end caps have two bolts. '

Helical timing gear is utilized, the camshaft gear. being of bronze. There is, however, a skew gear driving the cross-shaft for the magneto at the left and the centrifugal Water pump at the right. The magneto is a ',was with a Simms vernier coupling and variable

ignition • Mixture distribution is effected within the cylinders; but there is an• exhaust manifold, and a hot-spot is provided by passing the short inlet connection betweenthe central arms of the exhaust manifold.

Carburation : is . effected by a Zenith instrument of the vertical, triple-diffuser pattern.

The starting .bandle is mounted in an extension bracket carried on a portion of the timing-case cover, the extension also forming the for ward support for the unit. •

It is interesting to note that the detachable head is removable in less than seven minutes, also that the combustion chambers are completely machined to ensure uniform compression and to permit a high ratio. Consequently, an excellent power output with low fuel consumption is obtained.

The cast-aluminium fan is mounted on ball bearings on an eccentric spindle which permits ad, justrnent of the Vee rubber belt.

A flange fitting is provided at each side of the engine so that the dynamo can be located in either position. The magneto can be slid back along its platform to permit adjustment of the vernier coupling, and the oil level is indicated by a dip stick at the near side. Oil replenishment is effected through a filler in the cylinder-head cover.

There are two large inspection covers for the big-ends, each held by eight screws.

The system of lubrication is most complete, the oil being fed under pressure from a submerged gear, type pump driven from the cktishaft,

to an external filter chamber, from which it passes to the main bearings and through the drilled crankshaft to the big ends. Anotherfeed goes through the filter to the hollow valverocker shaft. The oil-relief valve is situated at the rear a the cylinder head, immediately above the inlet to

the rocker shaft. . • .

An inspection cover is provided for the Beadix drive .of the starter and anather on thellYwheel housing to 'permit inspection of the timing marks. Starter teeth are cut direct on the semi-steel flywheel.

As already mentioned, the drive is taken through a singledry-plate clutch_ This has 12 pressure springs and is. of simple construction.

An unusual point regarding the change-speed gear is that the control lever can be •mounted centrally or at the right of the driver, to choice. In the latter case, it is carried on a cast-aluminium extension of the top cover, which contains the selector . mechanism. The gearbox is a onepiece casting with a small separate casting at the near side forming the oil tiller. A power take-off is • arranged for at the off side of the layshaft, and a positive spiral-gear drive for the speedometer is taken off the third,motion shaft. The gears have wide teeth and are mounted on short rigid shafts. The position of the clutch pedal can be adjusted, as it is mounted upon serrations, whilst the pedal plate is also on an adjustable screwed spindle. The gear ratios are as lollow:—Top, direct ; third, 1.7 to 1; second, 2.61 to 1; first, 5.27 to 1 ; reverse, 8.23 to 1. With a backaxle ratio of 6.75 to 1 and 34-in. by 7-in. tyres at the rear, the road speed is 15.1 m.p.h. at 1,000 r.p.m. of the engine.

• The rear axle is a horizontal banjo forging with an overhead worm, the latter being mounted on ball and roller Hoffmann bearings and provided with a double-thrust race.

The wheels are mounted on taperroller bearings and the splined axle shafts are fixed in the driving caps and can be pulled out of the differential without removing the wheels, so permitting the whole of the gearing to be withdrawn for inspection or repair.

Duplex brakes are embodied in the rear drums, the foot brake being controlled through a link compensator on the cross-shaft, whilst the hand' brake is non-compensated. All the levers on the shafts are held by serrations and cotter-pins. Adjustment of the foot brake is effected by a turnbuckle on the forward rod, whilst both this and the hand brake have snap-over wiugnuts at the ends of all the rods. Forgings are utilized for the brake drums, which have deep flanges and dust covers.

The chassis frame is perfectly straight, but with the side members tapered to front and rear. The material is fin, pressed channel 6 ins, deep with 21-in. Ranges. There is a deep, dropped, channel-section cross-member at the front, then two arched, tubular members and, finally, an inverted channel. Pressedsteel • spring ,brackets are bolted through to cross-members.

The suspension is excellent, the springs being overshing with a pimple in the centre of each leaf to avoid weakening by holes, and the ends of the second leaves are carried under, the byes, which are bushed.

Tecalemit-Zerk lubricators are fitted throughout the chassis.

The front axle is a reversed Elliott with ball joints for the brake rod and drag link.

The wheels are of the eight-stud steel-disc pattern with single pneumatic tyres, 33-in. by 5-in, at the front and 34-in. by 7-in, at the rear.

Petrol is 'gravity fed to the carburetter from an 8a-gallon tank on the dash behind the instrument board. A well-polished cast-aluminium radiator with vertical gilled tubes adds to the appearance.

The main dimensions, etc., of the chassis are :—Wheelbase, 11 ft. 2 ins.; overall length, 16 ft. 8-1 ins.; dash to end of frame, 12 ft. 61 ins.; laden height, 2 ft. 5 ins.; ground clearance, under front axle, 121 ins., under rear axle, 111 ins.; turning circle, 49 ft. ; chassis. weight, 31 cwt.