NEAT OUTFIT KEEPS THE LAKES TIDY

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

Private waste contractor Peter Graveson has developed a specialist service which is in tune with its environment and up-market clientele. David Wilcox reports

El EY were designed to be bearproof, although we don't have too many problems with bears here in the Lake District."

The bear-proof objects arc rubbish bins owned by Carnforth-based waste contractor Peter Graveson. They are part of a system that he saw while on holiday in the Rocky Mountains of Canada four years ago. He was so taken with this Canadian Haul-All equipment that he is now using it on some of his own work in the Lake District.

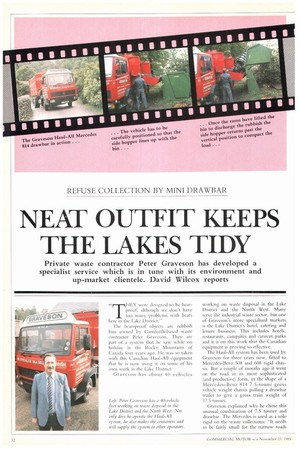

Graveson has about 40 vehicles Lift: Peter Graveson has a 40-vehicle fleet work* on waste disposal in the Lake District and the North West. Not only does he operate. the Haul-All system, he also makes the containers and will supply the system to other operators. working on waste disposal in the Lake District and the North West. Many serve the industrial waste sector, but one of Graveson's more specialised markets is the Lake District's hotel, catering and leisure business. This includes hotels, restaurants, campsites and caravan parks and it is on this work that the Canadian equipment is proving so effective.

The Haul-All system has been used by Graveson for three years now, fitted to Mercedes-Benz 508 and 608 rigid chassis. But a couple of months ago it went on the road in its most sophisticated (and productive) form, in the shape of a Mercedes-Benz 814 7.5-tonne gross vehicle weight chassis pulling a drawbar trailer to give a gross train weight of 17.5 tonnes.

Graveson explained why he chose this unusual combination of 7.5 tonner and drawbar. The Mercedes is used as a solo rigid on the waste collections: "It needs to be fairly small for the narrow roads

up here and to manoeuvre in and out of the hotels."

With relatively few tips and low average speeds in the Lakes, journeys to discharge the waste are slow, and so costly. That is where the drawbar comes in: its coupled-up capacity enables Graveson to reduce the number of runs Lo the tip.

W HAT initially attracted Graveson to the Haul-All system was its neatness. "It has to be environmentally acceptable for the Lake District. It also has to be fairly up-market for the high-class hotels and restaurants."

On each half of the Mercedes drawbar is a 9.2m3 (12yd3) compacting container which is demountable by means of a Multilift Hooklift system, The two containers can also be tipped to discharge via rear doors.

The system, which is the only one of its kind in the UK, works like this: the 3m3 (4yd3) "bear-proof bins, which are permanently sited at the hotels and campsites, can lift a full bin and discharge it into the side hopper of the Mercedes' container body. These rams are powered from the vehicle's power take-off.

Once the rubbish is in the side hopper this is powered upright past its starting position so that it compacts the rubbish inside the body. Because of this compaction each 9.2m3 container body can accomodate the contents of five 3m3 bins.

To cater for smaller customers like cafes which do not need this size of bin, the equipment can also work with smaller, wheeled plastic bins. These 660-litre capacity units can be clipped to the side of the Mercedes' hopper. When this is powered upright the contents of the bin are emptied into the body.

Alternatively, conventional black plastic bags can simply be loaded into the hopper. Whichever method of loading is used, the waste can still he compressed by the body in its compaction cycle.

The environmental advantages of the system become obvious as soon as one sees it in operation. Running solo, the 7.5-tonne Mercedes is unobtrusive in the narrow Lakeland towns, and it certainly looks suitably "up-market" for Graveson's customers.

It is also surprisingly quiet in operation while the bins are discharging their load. Indeed, the 814 on tickover is far quieter than the average refuse collection vehicle.

The bins, too, are designed to be unobtrusive. They are painted green and are sprayed with disinfectant from a tank on the Mercedes after each collection. A disadvantage of the system, though, is the high price of each bin — they are almost .$:1,000. Admits Graveson: "They are the most expensive, over-engineered bins. But because we don't actually pick them up or -handle them they should last a very long time and so we can write them off over a long period."

GRAVESON has almost 80 bins on sites in the Lake District. He has won business in competition with the local authority, even though his prices are higher. He attributes this success to a tidier, cleaner system and a better service.

The local authority still uses black plastic bags and charges on a rate-perbag basis. And whereas the authority gives a fixed weekly or fortnightly collection, Graveson collects on demand. His vehicles are radio-controlled and a telephoned request will result in a collection the same day. Because of the 814 drawbar's sophisticated body and demount equipment, its payload is reduced to around 8.5 tonnes. Despite this, Graveson says that the vehicle is more productive in terms of revenue earning than many of the larger six and eight-wheel mobile compactors in the fleet.

He points out that the 814 drawbar/Haul-All combination is a relatively "high-tech" solution and was expensive to buy. But his costings show that the capital cost of a vehicle on his type of work is a smaller than average proportion of total operating costs; running costs are much more significant. Operating in the Lake District entails steep gradients and low speeds, pushing up fuel consumption, brake wear and journey times.

Similarly, manoeuvring at collections and running onto tips gives transmissions and tyres a hammering. Graveson is an advocate of automatic transmission to reduce transmission and tyre wear, and has Allison automatics fitted to four Leyland Scammell Contractor 30.25 eight-wheel rear-end loaders. ZF Transmatic is fitted to five Mercedes — the first choice of vehicle in this waste disposal fleet.

As a result of this cost breakdown Graveson calculates that the 814 drawbar's ability to reduce the number of trips to the tip lowers the running costs to a point that easily compensates for its high purchase price.

However, the initial cost of the HaulAll containers and bins undoubtedly deters other operators. Graveson has the UK licence to manufacture the containers, but he remains the system's only UK operator. Having used it for three years he is convinced that it can prove its worth in other environmentally sensitive areas, particularly holiday destinations such as the West Country.