THE NEW E

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

)DGE 3 -TONNER

Proves the Practical Value of careful Design

ARECENT addition to the Dodge range is a new 3-ton chassis, and the long-wheelbase edition of this model, equipped with a drop-sided lorry body, forms the subject of our road test this week.

The new chassis is of straightforward design and is sturdily built, whilst the equipment is unusually comprehensive. The chassis layout follows modern practice, whilst the relatively large six-cylindered engine, coupled with a low overall weight, results in a high power-to-weight ratio being obtained, and the topgear performance is, in consequence, extremely good.

Inspection of the engine and chassis indicates that the machine has been designed and built to withstand hard usage, and the results of our tests lead to the belief that the excellence of the performance is

n36 allied to low operating and maintenance costs.

The engine has a bore and stroke of 31. ins. and 4i ins, respectively, the R.A.C. rating being 27.34 h.p. A maximum output of 85 b.h.p. is obtained at 3,200 r.p.m., but normally the engine is governed to 2,000 r.p.m., at which speed 65 b.h.p. is developed, and a road speed of 35 m.p.h. may be attained on top gear.

Engine Details.

Side valves are employed, the inlet valves being of chrome-nickel steel, whilst the exhaust valves are of heat-resisting silchrome. The valve guides are removable, and inserted seats of a hard alloy are used for the exhaust valves.

Crankcase ventilation is provided by means ofia copper-mesh air filter embodied in the oil-filler cap, whilst the crankcase gases are drawn out by

has a secondary valve which allows air to pass through the carburetter so soon as the engine fires, although fully choked.

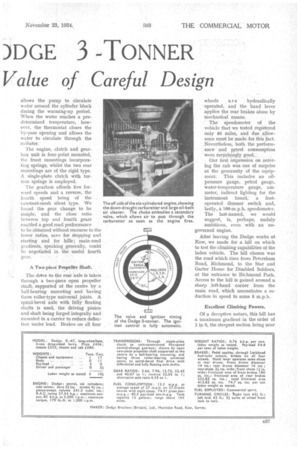

A Duplex oil-bath air cleaner is fitted above the carburetter. After entering the body of the device the air is directed downwards through a tapered compartment, at the base of which is an oil-bath. The increased velocity of the air stream at this point carries the heavier dust particles into the oil. The mixture of oil and partially cleaned air then passes upwards into a copper-mesh filter element, thus slowing down the air stream and allowing the oil to separate and flow down the conical filter element back to the base, through slots provided for this purpose.

The cooling system incorporates a by-pass thermostat, which does not cut off the water circulation, but allows the pump to circulate water around the cylinder block during the warming-up period. When the water reaches a predetermined temperature, however, the thermostat closes the by-pass opening and allows the water to circulate through the radiator.

The engine, clutch and gearbox unit is four-point mounted, the front mountings incorporating springs, whilst the two rear mountings are of the rigid type. A single-plate clutch with torsion springs is employed.

The gearbox affords five forward speeds and a reverse, the fourth speed being of the constant-mesh silent type. We found the gear change to be simple, and the close ratio between top and fourth gears enabled a good road performance to be obtained without recourse to the lower ratios, save for stopping and starting and for hills ; main-road gradients, speaking generally, could be negotiated in the useful fourth gear.

A Two-piece Propeller Shaft.

The drive to the rear axle is taken. through a two-piece open propeller shaft, supported at the centre by a ball-bearing mounting and having three roller-type universal joints. A spiral-bevel axle with fully floating shafts is used, the driving pinion and shaft being forged integrally and mounted in a carrier to reduce deflection under load. Brakes on all four wheels are hydraulically operated, and the hand lever applies the rear brakes alone by mechanical means.

The speedometer of the vehicle that we tested registered only 46 miles, and due allowance must be made for this fact.

• Nevertheless, both the performance and petrel consumption were surprisingly good.

Our first impression on entering the cab was one of surprise at the generosity of the equipmeat. This includes an oilpressure gauge, petrol gauge, water-temperature gauge, ammeter, indirect lighting for the instrument board; a footoperated dimmer switch and, lastly, a 100-m.p.h. speedometer. The last-named, we would suggest, is, perhaps, unduly ambitious, even with an un governed engine.

After leaving the Dodge works at Kew, we made for a hill on which to test the climbing capabilities of the laden vehicle. The hill chosen was the road which rises from Petersham Road, Richmond, to the Star and Garter Home for Disabled Soldiers, at the entrance' to Richmond Park. Access to the hill is gained around a sharp left-hand corner from the main road, which necessitates a reduction in speed to some 5 m.p.h.