KING OF THE CASTLE

Page 48

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

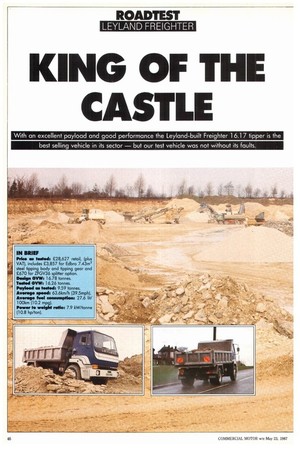

With an excellent payload and good performance the Leyland-built Freighter 16.17 tipper is the best selling vehicle in its sector — but our test vehicle was not without its faults.

• Appropriately enough, Leyland Dafs most powerful 16.26-tonne Freighter chassis, the 16.17, made its debut in tipper form three years ago at Tipcon.

Since then there have been several specification changes that have bolstered the Freighter's market lead. There is now the option of a "LF splitter gearbox and S-cam foundation full air breaks: the interior of the durable T45 cab has also received one or two modest refinements.

Of the four 16-tonners in the range, three are powered by Leyland's own 6.54 litre engine in 100, 115 and 128kW (135, 154 and 172hp) ratings. The fourth model, the 16.16, arrived early last month (CM 11 April). It is the first 16-tonner to feature the 114kW (153hp) Cummins-built Leyland 311 engine and looks like closing the gap in the Freighter range, as far as this engine is concerned.

Although the medium-powered 16.15 is still far and away the most popular with Leyland's customers, the 16.17 sells in sufficient numbers to make it an equally important part of the Freighter line-up.

As far as payload, performance and price are concerned, the 16.17 competes favourably on all counts. In chassis-cab form and with a full tank of diesel, it tips the scales at 4.66 tonnes to offer a body/ payload combination of 11.60 tonnes.

111 FUEL CONSUMPTION

Around our revised tipper route it looked rather less impressive in terms of fuel efficiency — a factor that might become crucial in any future debate by Leyland Daf over which engine should power the Freighter. On the motorway section the fully-laden 16.17 returned 28.5fit/100km (9.9mpg) at an average speed of 90.6km/h (56.3mph). Over A roads it performed a little better, with 27.1lit/1001on (10.42mph) at an average 53.8km/h (33.4mph).

Although it is the first 4x2 to be driven around our revised tipper route, its overall figure of 27.61it/100km (10.2mpg) at 63.6km/h (39.5mph) bears comparison with the most frugal three-mded 24-tonner tested over the route so far; the Cummins-engined lveco Ford Cargo 6x4 2424C (CM 13 December 1986).

Its final result of 30.71it/100km (9.2mph) at 66.1krn/h (41.1mph) is not too far behind that of the 16.17 Freighter, yet it carried 44.4% more payload at 14.64 tonnes. There are also mitigating factors that deserve mention, including the excessive amount of black smoke that emanates under load to leave its tell-tale mark on the front of the tipping body.

The body bulkhead forms an effective wind scoop which creates considerable resistance, particularly at motorway speeds. Together with the box-section side-pillars this must increase the overall drag factor, to the detriment of the fuel consumption.

Eighteen months ago in a 16-tonne group test and under comparable weather conditions a well run-in platform-bodied 16.17 with a similar driveline performed considerably better over our Welsh test route, returning almost 23.514/100km (12mpg) at a slightly faster average of 64krn/h (40mph).

Apart from the 16.17 tipper's mere 9,700km on the clock, these figures illustrate the effect that varying body types have on the model's performance.

• DRIVEUNE

A close kook at the 16.17's well established driveline gives a clue to its sharp on-road performance.

The 128kW Leyland turbocharged 420 engine drives through a fairly hefty 381mm (15in) diameter single-dry-plate clutch and the optional ZF S6-36 splitter gearbox to the Leyland hub-reduction drive axle.

With the GV36 splitter which gives upward splits on the ratios, an 0.83:1 top gear, 5.55:1 final drive and 11R 22.5s at the rear, the 16.17 has a maximum theoretical top speed of 103km/h (64mph). In practice (and with a following wind) it actually ran out at 116km/h (72mph).

One of the 16.17's more endearing qualities is the engine's crisp, positive acceleration which, together with abundant, well-chosen gear ratios, encourages a relaxed driving style while still allowing good journey times.

This is only marred by a fairly ponderous clutch pedal and what is becoming all-too-common on Leyland middleweights — an acutely-angled accelerator that soon causes discomfort if you attempt to drive with your foot fiat on the pedal_

• PERFORMANCE

As far as power and acceleration is concerned, the test vehicle turned in very quick times that compare well with current Daf and Volvo 16-tonners.

From 0-80km/h the 16.17's 63.1 seconds is 18 seconds faster than the naturally-aspirated 113kW Daf FD2100 tested last year (CM 28 June), but six seconds behind the Volvo FL616 with its charge-cooled 151kW engine (CM 5 April 1986). ERF's E6.18 (CM 1 November 1986) with the ZF six-speed gearbox and the same 126kW charge-cooled Cummins 'B' series engine that is used in Leyland's experimental TX450 had much more pace, cutting 10 seconds from the 16.17's 080Ian/h time.

The 6.5 litre engine develops its 574Nm (4231bft) maximum torque at 1,600rpm, but even at the 70mph (96km/h) motorway limit it still produces in excess of 542Nm (4001bft).

Between 64 and 801cm/h in 11th and 12th gear engine revs hover around 1,550-1,9501pin, running at its peak torque for good performance and, in theory, fuel economy. Whatever the limit, the Freighter 17.17 cruises effortlessly without ever sounding under any strain.

Setting off on the fiat requires full gear changes beginning with 2nd-high, but this can be varied by half a gear depending on the gradient. Slowing to approach roundabouts or junctions in built-up areas in 5th-high or 6th-low calls for just one full down-change to pull away confidently.

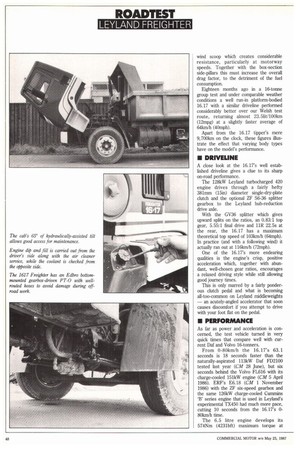

In quarry sites, despite not having the benefit (or choice) of a differential lock, the 16.17 never feels troubled by heavy mud or loose gravel. Here too its gradeability proved almost as effective as on the dry test slopes at the MIRA proving ground where it only just failed to re-start on the 33% (1-in-3) gradient.

• BRAKING

Although its park brakes proved very effective on the test hills, on MIRA's test tracks the foot brakes revealed an imbalance across the rear axle. This appeared during a full-pressure stop from 48km/h in the form of a rear-end pull to the left, but manifested itself as a sharp swing to the right from 64krnfh.

Fortunately during normal road use there was no sign of any abnormality and the brakes behaved satisfactorily throughout the period of the test.

• SUSPENSION

Ever since the T45 Freighter launch in 1981 Leyland has pinned its faith in semielliptic taper leaf springs. While other manufacturers fit double-acting hydraulic dampers at the rear, or supply anti-roll bars, Leyland perseveres with two-leaf slipper-ended helper springs.

Judging by the way that this Freighter behaved on MIRA's severe ride-andhandling course it is still a very capable basic specification that gives a wellcontrolled ride at normal road speeds. In addition to feeling very stable on the road the 4.0m-wheelbase 16.17 has a fairly small 15.5m (51ft) kerb-to-kerb turning circle and feels very maneouvrable indeed — despite the noisiest and most sluggish power-assisted steering we have encountered for some time.

Although the engine's tickover is uneven and often falls below 500rpm, even at 1,1001pm there is still intermittant drag on both sides of centre, as though there is air in the system.

To overcome this the revs were raised just a bit higher, removing any resistance.

• CAB COMFORT

Leyland's enduring 145 cab, which was treated to a number of minor improvements in time for last year's Motor Show, is easily accessible and comfortable.

Its entry steps are well spaced and outside the line of the cab with handy grab rails, while the driver's suspension seat and steering column adjust to suit most requirements. The low engine tunnel allows easy cross-cab movement.

Apart from a rather rattly exhaust, as though the baffles are loose in the silencer, in-cab noise levels are quite acceptable.

Seats and the cab interior are trimmed with light-coloured but easily-cleaned materials while the floor is covered with black rubber matting and looks as though it can be hosed out with little fuss.

• SUMMARY

The Leyland-built Freighter 16.17 tipper is part of a range that has been a market leader since its introduction six years ago.

It offers excellent payload potential, high levels of performance and is relatively easy to maintain.

With just 10,000kms on the clock the fuel consumption will probably improve, but its smoky, rattly exhaust, heavy steering and out-of-balance brakes spoilt an otherwise impressive performance.

Of the 10,180 4x2 rigids over 15tonnes GVW registered last year, Leyland's Freighter accounted for about 21%, and a third of those were tippers. By comparison, the new company's Eindhoven-built rigids fared less well with only 5% — which was slightly down from the 1985 figure.

This sales imbalance for the UK must fuel speculation over which marque should survive the rationalisation programme that is already under way.

However much Leyland Daf manoeuvres, at the end of the day operators have their own bottom lines — and their buying policies are directly influenced by price, payload and performance. Perhaps with the reputedly more fuel efficient '300' series, the Freighter will live on.

by Bryan Jarvis