MATE HANDLING EXHIBITION

Page 54

Page 55

Page 56

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

JAPANESE, American and East European exhibits provide the international flavour at the third International Materials Handling Exhibition, which ends its six-day run at the Kelvin Hall, Glasgow, tomorrow. Sponsored by the Institute of Materials Handling, this year's exhibition is the most comprehensive of its kind to have been mounted in Scotland and the biggest to be held in the UK in 1969. More than 100 exhibitors are showing materials handling equipment ranging from polythene bins to fork-lift trucks with electronic systems developed for the American Apollo spacecraft.

Advanced electronics

Selections from the Allis-Chalmers range of electronic, diesel and gas fork-lift trucks are shown by Reddey Mechanical Handling Ltd. (stand 62). It is this company's elec tronic trucks which have the unique feature of including an electronic system developed by Allis-Chalmers for the US Apollo spacecraft and adopted for use in the trucks some six years ago.

The control system in these trucks is based on a bank of power transistors, in place of the thyristors which are becoming more commonly used in the manufacture of such equipment, with a frequency of 120 cycles per second and pulse width modulation.

The company claims that the advanced electronics prevent the trucks from being overstrained—the motor, for example, will cut out before it is allowed to burn itself out—and a new feature, introduced at the exhibition, is the addition of a protective circuit board which reduces damage to the system to a minimum in the event of mal

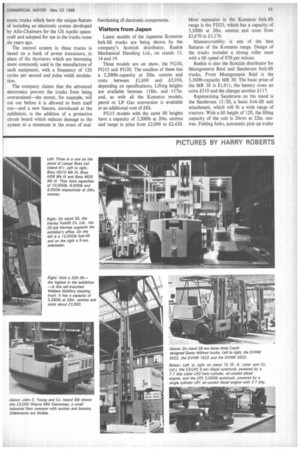

functioning cif electronic components. Visitors from Japan Latest models of the Japanese Komatsu fork-lift trucks are being shown by the company's Scottish distributor, Reekie Mechanical Handling Ltd., on stands 13, 14 and 19.

Three models are on show, the FGIO, FG15 and FG20. The smallest of these has a 2,200lb-capacity at 20in. centres and costs between £1,690 and £2,010, depending on specifications. Lifting heights are available between 118in. and 157in. and, as with all the Komatsu models, petrol to LP Gas conversion is available at an additional cost of £84.

FG15 models with the same lift heights have a capacity of 3,300lb at 20in. centres and range in price from £2,090 to £2,420. Most expensive in the Komatsu fork-lift range is the FD25, which has a capacity of 5,5001b at 20in. centres and costs from £2,670 to £3,176.

Manoeuvrability is one of the best features of the Komatsu range. Design of the trucks includes a strong roller mast with a lift speed of 87ft per minute.

Reekie is also the Scottish distributor for Montgomerie Reid and Sanderson fork-lift trucks. From Montgomerie Reid is the 3,3601b-capacity MR 30. The basic price of the MR 30 is £1,911, the battery costs an extra £310 and the charger another £117.

Representing Sanderson on the stand is the Sanderson 12 /20, a basic fork-lift unit attachment, which will fit a wide range of tractors. With a lift height of 12ft, the lifting capacity of the unit is 20cwt at 22in. centres. Folding forks, automatic pick-up trailer hitches and a pallet box tippler designed for the handling of potatoes are among the accessories available with the unit.

Examples of Lancer Boss Ltd.'s Boss Mk III fork-lift trucks are being exhibited for the first time in Scotland on stand 41.

The company has also taken the demonstration arena to show in action its range of front-lift trucks and sideloaders—including a Lancer 2500 series sideloader with traversing cab for lifting and loading 20ft, 20-ton ISO containers.

The biggest front-lifting truck in Europe—the 81,000lb-capacity Boss Mk on show along with the 5,000lb-capacity PD5, the 7,000lbcapacity MD7, the 8,000lb-capacity HD8, the 10,0001b-capacity HDIO and the 15,000lb-capacity C D 15.

Representing the Boss P and M series electric trucks at the exhibition are the 5,000lb-capacity PE5 and 7,000lb-capacity ME7. Both feature the Boss-Westinghouse SCR Supertronic fixed-frequency pulsecontrol system.

The traction motors in these trucks are direct-mounted to the drive axle, eliminating all transmission linkage. Similar advantages are gained from the direct-mounting of the hydraulic pump to the pump motor, which is mounted on hinged panels for ease of access. Full hydrostatic power steering is provided in the Boss M series.

Full Crown range

The full range of equipment made by Crown Controls Ltd. is being shown on stand 43.

The Crown Shuttle hand-pallet truck is designed for the handling of fragile loads and has a capacity of 4,500lb. It is available in six standard sizes and has polyurethane wheels with sealed bearings, nylon rollers, an articulated steering wheel and a 200deg turn.

There are four models in the Crown P series of counter-balanced fork-lift trucks, the P12, P16, P20 and P25, with load ratings of 1,3001b, 1,760Ib, 2,200lb and 2,7501b respectively at 20in. centres.

On all models, each of the front wheels is driven by an independent motor, powered through a closed spur-gear system contained in an oil bath and gear chain with electrical cut-out differential action. All machines have five forward and five reverse speeds, controlled by a switching relay.

All models are fitted with Magnetrol—a specially wired motor which eliminates the necessity for resistances. The power is taken from the battery only in amounts required, resulting in battery savings of up to 60 per cent for extended operation in lower speeds.

The Crown series V stackers are power driven and are made in two models with capacities of 1,5001b and 2,000lb respectively. Loads can be power-lifted to heights of from 54in. to 130in. in aisles as narrow as 5ft 8in. Both models are equipped with 12V batteries and built-in chargers.

18,000lb Fork-lift

The central exhibit shown by Yale Materials Handling Equipment (stand 26) is the 18,0001b-capacity diesel fork-lift truck shown publicly for the first time at the Ports and Terminals Exhibition in April.

Designed mainly for work at ports and freight terminals, timber yards, steel works and brick and concrete plants, the truck has dual-lift cylinders positioned to give good through-mast visibility for the driver, maximum lift and travel speeds and accessibility.

The truck is provided with hydrostatic power steering, air brakes, an air-operated hand brake and automatic transmission with three forward and three reverse speeds. The tilt cylinders act high on the mast to reduce mast distortion, improve load stability and minimize operating forces. The counterweight and rear axle form a single integrated unit which can be withdrawn to expose the engine for overhaul.

Other features include two-speed hoisting and a pedal-controlled inching ,system, which allows the truck to creep while full power is used for hoisting. The canopy guard is an integral part of the machine and can be fitted out to provide a fully weatherproof cab. The forks are hinged so that they can be swung upwards within the truck's length for travel.

The truck has an outside turning radius of 150in. and a right-angle stacking with 48in. forks of 227in. length. It will lift loads up to 18ft with the standard mast, which can be tilted 6deg forward and 12deg backward. The maximum travel speed is 26 mph and the machine can negotiate one-in-three gradients fully loaded.

New Lister conveyor

A newly introduced mobile industrial conveyor, manufactured by R. A. Lister and Co. Ltd., is making its debut on stand 72. Examples from the company's ranges of dieseland electric-powered trucks and tractors are also featured, several on show for the first time in Scotland.

The new conveyor. the PL14, is suitable for handling a wide variety of goods in most types of warehouse and storage area. It is powered by a 2 hp electric motor and can carry a 3361b distributed load to a 16ft delivery height at 60ft per minute.

The machine can be loaded at ground level and deliver goods to between 6ft 10in. and 14ft. The height range is increased by equipping the conveyor with a pair of adjustable legs at its loading end. When these legs are fully extended, the loading height becomes 3-1-ft with delivery heights between 41-ft and 16ft. The machine's height and angle of operation are adjusted by a mechanical jacking arrangement.

On show for the first time in Scotland is a Lister 3E fixed-platform electric truck with a payload capacity of 4,400lb. The truck has a contr.ol system incorporating a carbon pile controller, specially developed by Lister, which requires only the simplest mainten

ance and keeps battery consumption to a minimum under all working conditions.

The company's industrial tractors are represented by two diesel-powered units, the 4D and CS /LR2 types, and an electric model, the Lister 4E unit. These tractors have a range of drawbar pulls from 7501b to 2,0001b. An industrial trailer which has a 2 ton payload capacity is also on view.

The SCS12 horizontal static industrial conveyor, fitted with a three-phase electric motor, is at the exhibition. The conveyor is 12ft long with a 2ft-wide track and can carry a 43cwt distributed load at 60ft per minute.

Also shown in Scotland for the first time are two Lister Graiseley vehicles. These comprise a pedestrian-controlled electric platform truck with a 2,2001b capacity and an electric pallet truck which can carry a 3,3001b payload.

Collapsible containers

A new collapsible container is being shown by IBC Transport Containers Ltd. on stand 2, that of Inglis Engineering along with the standard IBC Big Bag and Compac models.

Known as the Palsac, the new container has a similar body to the Big Bag—a cylindrical container with a conical bottom; but instead of incorporating a steel collar which must travel with the bag, full or empty, a new folding steel collar is used. It is of all-welded steel tube with what is claimed to be a unique locking device and system of attaching to the bag. Consequently the bag travels without any metal attachments and only two or three collars are needed for each traffic pattern.

The bag has a volume of up to 80 Cu. ft., a load-carrying capacity of 2 tons and weighs 251b. Its collapsed vOlume is one cu. ft. Palsac can be used with standard wooden pallets or with the Big Bag steel pallet tray.

Prices of the Palsac models are as follows: Model A, 1,000 litres /35 cu. ft., £25 13s to £28 7s according to quantity; Model B, 1,500 litres /53 Cu. ft., £26 lOs to £29 5s; Model C, 1,500 litres /53 cu. ft. but with larger diameter than B, £28 14s to £31 14s; Model D, 2,000 litres /70 Cu. ft., £31 4s to £34 14s. The collapsible collar costs £29 10s.

Mintech

A chain hoist which can move a load to any position in a vertical plane with great accuracy is on show for the first time by the Ministry of Technology (stand 36).

The exhibit has been converted from a normal chain hoist to two-axis electronic control by applying Hi-syn positional electronic control units. These units have been successfully applied over a wide range of mechanisms including the loading and unloading of automatic lathes.

The chain hoist on show demonstrates how positioning of the hook can be programmed in both the hoisting and lowering operations, the programme being varied to suit individual applications.

Drives of this type can be fitted to mechanisms which require a repeatable cycle of operations. The number of axes is not limited and the programme and range of motion can be readily changed.